Longevity Tips: Extending Life of Volvo Excavator Brake Discs

- Maximizing Brake Disc Service Life for Volvo Excavators

- Understanding the brake disc role and common failure modes

- Why OEM-quality discs matter: product-specific considerations

- Key inspection checkpoints

- Routine Maintenance & Measurement Techniques

- How to measure and interpret disc thickness and runout

- When to resurface vs replace

- Recommended maintenance intervals and record-keeping

- Installation, Bedding, and Operational Best Practices

- Correct installation steps to avoid premature wear

- Bedding in new discs and pads

- Operational tips to prevent overheating and thermal damage

- Troubleshooting, Corrosion Protection and Parts Selection

- Common symptoms and root-cause checks

- Anti-corrosion strategies for long service life

- Choosing the right replacement: OEM vs aftermarket

- Comparison: Resurfacing vs New Disc

- Brand Advantages and Why SPARKLING MACHINERY VOE14558962 Is a Smart Choice

- OEM compatibility and tested performance

- Durability features

- Support and traceability

- Frequently Asked Questions (FAQ)

- Q1: How often should I replace the brake disc on my Volvo EW160/180?

- Q2: Can I use resurfaced discs indefinitely?

- Q3: What are the easiest ways to prevent corrosion on discs?

- Q4: Is special bedding required for SPARKLING MACHINERY discs?

- Q5: Where can I get the right VOE14558962 part?

Extending the service life of brake discs on wheeled Volvo excavators is both a safety priority and a cost saver. This guide synthesizes field-proven maintenance practices, inspection techniques, and installation best practices tailored for models EW160C/D/E and EW180C/D using the VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 DISC BRAKE SPARKLING MACHINERY unit. It helps fleet managers, technicians and procurement specialists reduce downtime, avoid unexpected brake rotor failures, and comply with OEM performance expectations. Extended service life also contributes to smoother operation, highlighting the performance impact of high-quality brake discs on excavators.

Maximizing Brake Disc Service Life for Volvo Excavators

Understanding the brake disc role and common failure modes

The brake disc (rotor) is the rotating component that converts kinetic energy into thermal energy through friction with brake pads. In excavators, discs face combined stresses: high torque during road travel, frequent stop-and-go in municipal sites, and abrupt loads when loading/unloading materials. Typical failure modes include wear (thinning), thermal cracking, corrosion, uneven surface glazing, and excessive runout. Familiar semantic keywords you’ll see in this article include rotor, friction surface, brake pad, caliper, runout, thermal cracking, and resurfacing.

Why OEM-quality discs matter: product-specific considerations

The SPARKLING MACHINERY NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 Disc Brake is built to VOLVO OEM standards and rated to operate from -30°C to 90°C while resisting wear and corrosion. Using OEM-grade rotors reduces risks of mismatch in thickness, balance and heat capacity — all factors that influence disc life. Refer to Volvo Construction Equipment for model compatibility and OEM guidance: Volvo CE.

Key inspection checkpoints

- Measure disc thickness at multiple points to detect uneven wear.

- Check surface for heat spots or blue discoloration indicative of overheating.

- Assess runout using a dial indicator; excessive runout (> manufacturer spec) causes vibration and pad wear.

- Inspect mounting bolts, hub interface, and anti-corrosion coatings.

Routine Maintenance & Measurement Techniques

How to measure and interpret disc thickness and runout

Use a micrometer to measure disc thickness in at least four quadrants near the friction surface to detect taper. Compare readings to the manufacturer minimum thickness. For runout, mount a dial indicator on a stable axle and rotate the wheel; runout exceeding OEM tolerances causes pedal pulsation and uneven pad wear. Typical acceptable runout for heavy equipment rotors is in the hundredths of a millimeter; check the excavator manual or consult the SPARKLING MACHINERY specification for exact tolerances.

When to resurface vs replace

Resurfacing (machining) can restore a rotor if thickness remains above minimum and there are no deep cracks or severe thermal damage. However, frequent resurfacing reduces metal thickness and heat capacity. Replace the disc when:

- Thickness ≤ manufacturer minimum

- Visible thermal cracks or severe heat-checking

- Runout cannot be corrected by machining or hub mounting

- Corrosion pits or compromised anti-corrosion layer

Recommended maintenance intervals and record-keeping

Create a simple log for brake inspections, including disc thickness readings, runout measurements, pad remaining thickness, and any resurfacing events. Example schedule:

| Operating Intensity | Inspection Interval | Typical Replacement Window |

|---|---|---|

| Light (mostly yard/low loads) | Every 250 hours | 2000–4000 hours |

| Moderate (mixed road/site) | Every 150 hours | 1500–3000 hours |

| Heavy (continuous heavy loading, steep gradients) | Every 75–100 hours | 1000–2500 hours |

Installation, Bedding, and Operational Best Practices

Correct installation steps to avoid premature wear

Follow the torque sequence and values for rotor mounting bolts to ensure even clamping. Clean hub mating surfaces to remove corrosion and debris; use anti-seize where specified to prevent galvanic corrosion and ensure accurate torque readings. Incorrect hub mounting introduces runout and uneven pad contact. Always use OEM or OEM-equivalent fasteners and follow Volvo torque specs where available.

Bedding in new discs and pads

A proper bedding (break-in) process mates the pad friction material evenly to the rotor surface and reduces glazing. Recommended bedding routine for heavy equipment:

- Perform 5–10 controlled stops from low speed with light-to-medium braking.

- Follow with 3–5 moderate stops from higher speed (but avoid repeated hard stops that overheat the disc).

- Allow cooling periods between cycles to avoid thermal shock.

Improper bedding can cause uneven transfer layer formation and accelerate wear.

Operational tips to prevent overheating and thermal damage

Avoid prolonged continuous braking on long descents — instead use engine braking where possible. Distribute braking evenly across axles and avoid riding the brakes when maneuvering around materials. If frequent stops are unavoidable, consider upgrading to discs with higher thermal capacity or improved cooling features. For technical background on brake thermal behavior, see the Brake disc (rotor) overview.

Troubleshooting, Corrosion Protection and Parts Selection

Common symptoms and root-cause checks

If you detect vibration, noise, or reduced braking performance, perform a systematic check:

- Vibration: measure runout and check wheel hub mounting.

- Squeal/noise: inspect pad compound and surface glazing.

- Reduced stopping distance: measure pad remaining thickness and check hydraulic/hose conditions.

Anti-corrosion strategies for long service life

Heavy equipment operating in corrosive environments (salt, coastal, chemical sites) needs extra protection. Options include protective coatings on non-friction surfaces, regular cleaning of exposed interfaces, and using stainless or coated fasteners. The SPARKLING MACHINERY disc for Volvo models includes anti-corrosion treatment to extend service in harsh environments.

Choosing the right replacement: OEM vs aftermarket

When selecting a replacement, prioritize fit, material quality, and dimensional tolerances. The full product name to consider is: VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 DISC BRAKE SPARKLING MACHINERY. Buying a part that meets VOE14558962 OEM standards ensures correct heat capacity, balance and mounting compatibility. For vendor certification and specifications, check the manufacturer documentation and verify testing procedures and material traceability.

Comparison: Resurfacing vs New Disc

| Factor | Resurfacing | New Disc (OEM quality) |

|---|---|---|

| Cost | Lower per event | Higher up-front |

| Remaining life | Reduced with each cut | Maximum |

| Heat capacity | Decreases after cuts | Optimal |

| Risk of hidden cracks | Higher (may be missed) | Lower (new material) |

Brand Advantages and Why SPARKLING MACHINERY VOE14558962 Is a Smart Choice

OEM compatibility and tested performance

SPARKLING MACHINERY's VOLVO-compatible disc meets VOE14558962 specifications and has been tested under vibration, friction, and temperature cycles. Choosing a tested product reduces risks of unexpected fitment problems and brake inconsistencies under load.

Durability features

Key engineered benefits include high-wear alloy formulation, controlled surface hardness to resist glazing, and corrosion-resistant coatings. These features translate into longer intervals between replacements and more predictable wear patterns.

Support and traceability

Reputable suppliers provide traceability for materials and batch testing certificates. This reduces warranty issues and supports fleet auditing requirements. For broader OEM guidelines and component safety, consult authoritative references like SAE International.

Frequently Asked Questions (FAQ)

Q1: How often should I replace the brake disc on my Volvo EW160/180?

A: Replacement depends on operating conditions, but typical windows range from 1,000 to 4,000 hours. Follow inspection intervals (75–250 hours depending on load), measure thickness and runout, and replace when thickness reaches the manufacturer minimum or when thermal cracks are present.

Q2: Can I use resurfaced discs indefinitely?

A: No. Each resurfacing reduces material thickness and heat capacity. If the disc requires frequent resurfacing or if you detect cracks or severe heat damage, replace it with an OEM-equivalent like VOE14558962.

Q3: What are the easiest ways to prevent corrosion on discs?

A: Regular cleaning, protective coatings on non-friction surfaces, using coated fasteners, and storing equipment indoors when possible. For discs with factory anti-corrosion treatment, keep mounting surfaces clean to maintain fit accuracy.

Q4: Is special bedding required for SPARKLING MACHINERY discs?

A: Yes — perform a controlled bedding-in sequence of light to moderate stops followed by cooling intervals to build a uniform friction transfer layer and avoid glazing.

Q5: Where can I get the right VOE14558962 part?

A: Contact SPARKLING MACHINERY or authorized distributors. To view product details or request a quote, visit: SPARKLING MACHINERY VOE14558962 Disc Brake. For OEM compatibility and Volvo model references, see Volvo CE.

If you need technical support or a quote for VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 DISC BRAKE SPARKLING MACHINERY, contact our sales team: sales@sparklingmachinery.com or view product specifications and order online: View Product.

Authoritative references used in this guide include the general brake disc overview on Wikipedia and technical standards and best practices from organizations such as SAE International and Volvo Construction Equipment (Volvo CE).

2026 Supplier Sourcing for Hydraulic System Components

Key Specs to Check When Purchasing HW210 Excavator Parts

What are the application scenarios of Excavator Swing Motor?

Hydraulic vs Mechanical Components: What to Expect

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

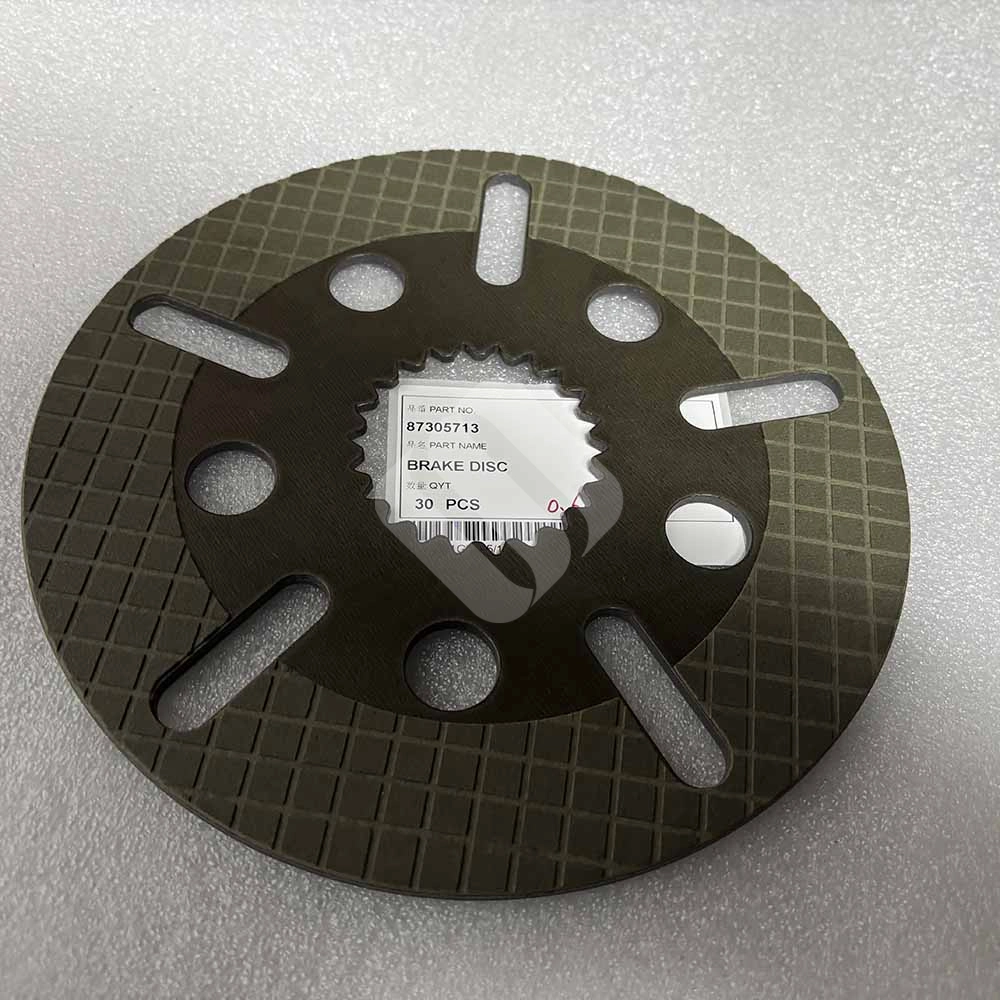

VOLVO HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B110B B100B LB90.B B90B B95B 87305713 BRAKE DISC SPARKLING MACHINERY

SPARKLING MACHINERY NEW B110B B100B LB90.B B90B B95B 87305713 Brake Disc is a core braking component for Volvo B110B/B100B/LB90.B/B90B/B95B excavators (heavy-duty construction/mining use). It works with brake pads to generate friction, ensuring reliable stopping and operational safety.

Meeting Volvo OEM standards (87305713), it resists -30°C to 300°C temps, wear, and thermal deformation, ensuring seamless compatibility and long-term reliable braking performance.

New Holland Backhoe Loaders 87305713 83959970 47123297 Brake Disc

87305713 is a specific industrial part number for a Brake Disc (or Friction Plate) used in agricultural and construction machinery, primarily manufactured by New Holland.

1.This friction disc is designed for oil-immersed (wet) braking systems. It is commonly found in:

New Holland Backhoe Loaders: Models including B90B, B100B, B110B, B115B, LB75, LB90, LB110, and LB115.

Ford Tractors: Series 550, 555, and 655.

Case IH: Certain models sharing the same drivetrain components

2. Technical Specifications

Outside Diameter (OD): ~204.75 mm

Inside Diameter (ID): ~55.88 mm (spline area)

Thickness: 4.8 mm

Teeth Count: 22 Teeth

Material: Paper-based friction material with a waffle-groove pattern for oil circulation and cooling

3. Cross-Reference Numbers

This part is often interchangeable with the following OEM and aftermarket numbers:

CNH: 83959970, 47123297

Ford/NH Original: E6NN2A097BB

Hyundai Wheel Loaders HL730-9 HL730-9A HL730-9S ZGAQ-03450 0501.323.355 DISC-INNER CLUTCH CHINA MADE

Part numbers 0501.323.355 (a ZF part number) and ZGAQ-03450 (a Hyundai part number) both refer to a Friction Disc used in the brake or clutch assembly of heavy machinery transmissions and axles.

This component is an inner clutch or brake friction plate/disc. It is a critical wear item within the drivetrain assembly (likely a ZF axle or transmission) responsible for creating the necessary friction to engage clutches or apply brakes in heavy equipment.

Compatible Equipment

This friction disc is commonly used in Hyundai wheel loaders and other construction equipment that utilize compatible ZF axles:

Hyundai Wheel Loaders: HL730-9, HL730-9A, HL730-9S, HL730TM-9A.

Other Compatible Equipment: Various backhoe loaders, including certain models by John Deere (e.g., 310, 315, 210K, 310SJ, 325K)

Part Numbers: 0501.323.355, 0501323355, ZGAQ-03450, ZGAQ03450, AT339543, 482-6743, VOE 15071853, S06/42932

ZTAM-00615 Support Kit Compatible with Hyundai R140W-7 & R140W-7A Wheel Excavators

ZTAM-00615 is an OEM-compatible support kit for Hyundai R140W-7/R140W-7A excavators. It provides essential structural reinforcement and vibration damping for key components, ensuring reliable performance under heavy loads and harsh working conditions in construction and engineering applications.

Key Features

· OEM direct‑fit design: Exact matching of mounting positions, hole spacing, and geometric dimensions for Hyundai R140W‑7 / R140W‑7A — plug‑and‑play without modification.

· High‑strength structural support: Heavy‑duty steel construction with reinforced stress points for excellent load capacity and impact resistance.

· Stable & durable: Anti‑wear, anti‑deformation, and anti‑corrosion surface treatment for long service life in harsh environments.

Compatible Models: Hyundai Wheel Excavators R140W-7, R140W-7A

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879