Compatibility Guide: Bearings for R210W-9 and R200W7A

- Understanding where bearings sit in the excavator drivetrain

- Which parts of an excavator rely on tapered roller bearings?

- How bearing function affects machine performance

- Regulatory and standards context

- Compatibility specifics: ZGAQ-02328 and Hyundai models

- About the product: HYUNDAI EXCAVATOR PARTS HW210 R200W7 R200W7A R210W-9 ZGAQ-02328

- Interchangeability between R210W-9 and R200W7A

- Quick comparison table: suitability for common bearing locations

- Installation, inspection and maintenance best practices

- Pre-installation checks

- Correct installation techniques

- Service intervals and monitoring

- Troubleshooting common bearing issues and repair choices

- Symptoms and root causes

- When to replace vs rebuild

- Case example: diagnosing a noisy final drive

- References and further reading

- FAQ

- Q: Is ZGAQ-02328 a direct OEM replacement for both R210W-9 and R200W7A?

- Q: How do I verify the right bearing dimensions for my machine?

- Q: Can I reuse old spacers or seals when fitting a new ZGAQ-02328 bearing?

- Q: What lubrication should I use for this tapered roller bearing?

- Q: How quickly will bearing failure spread to other components?

This Compatibility Guide explains how tapered roller bearings interact with the key rotating systems on Hyundai wheeled excavators—especially R210W-9 and R200W7A models—and how the SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing fits into those systems. It covers interchangeability, fitment checks, installation best practices, and maintenance steps for core components of an excavator such as the swing mechanism, final drive input shafts, and carrier assemblies. The information below is designed to help parts managers, service technicians, and fleet supervisors make correct replacement and compatibility decisions with confidence.

Understanding where bearings sit in the excavator drivetrain

Which parts of an excavator rely on tapered roller bearings?

Tapered roller bearings are commonly used in rotating assemblies that carry combined radial and axial loads. In wheeled Hyundai excavators like the R210W-9 and R200W7A, these bearings appear in or near the following parts of an excavator: the swing gearbox/slew ring interfaces, final drive input/output shafts, travel gearbox components, carrier shafts, and some pivot/steering linkages. Correct identification of the location reduces the risk of installing an incorrect bearing size or series.

How bearing function affects machine performance

Bearings support shafts and rotating housings and directly influence gear alignment, backlash, and load distribution. A properly chosen tapered roller bearing ensures smooth rotation under heavy loads from the boom, arm, and bucket, minimizes vibration transferred to the frame, and prevents premature wear of gears and seals. Poor bearing selection or installation increases heat, reduces efficiency, and can trigger secondary failures in hub seals or gear teeth.

Regulatory and standards context

Rolling bearing design and life calculations follow international standards such as ISO 281 for life calculation of rolling bearings. For more on ISO guidelines for bearing life and load ratings, see ISO 281:2007. For background on excavator systems and components, the general excavator overview on Wikipedia provides useful context: Excavator - Wikipedia.

Compatibility specifics: ZGAQ-02328 and Hyundai models

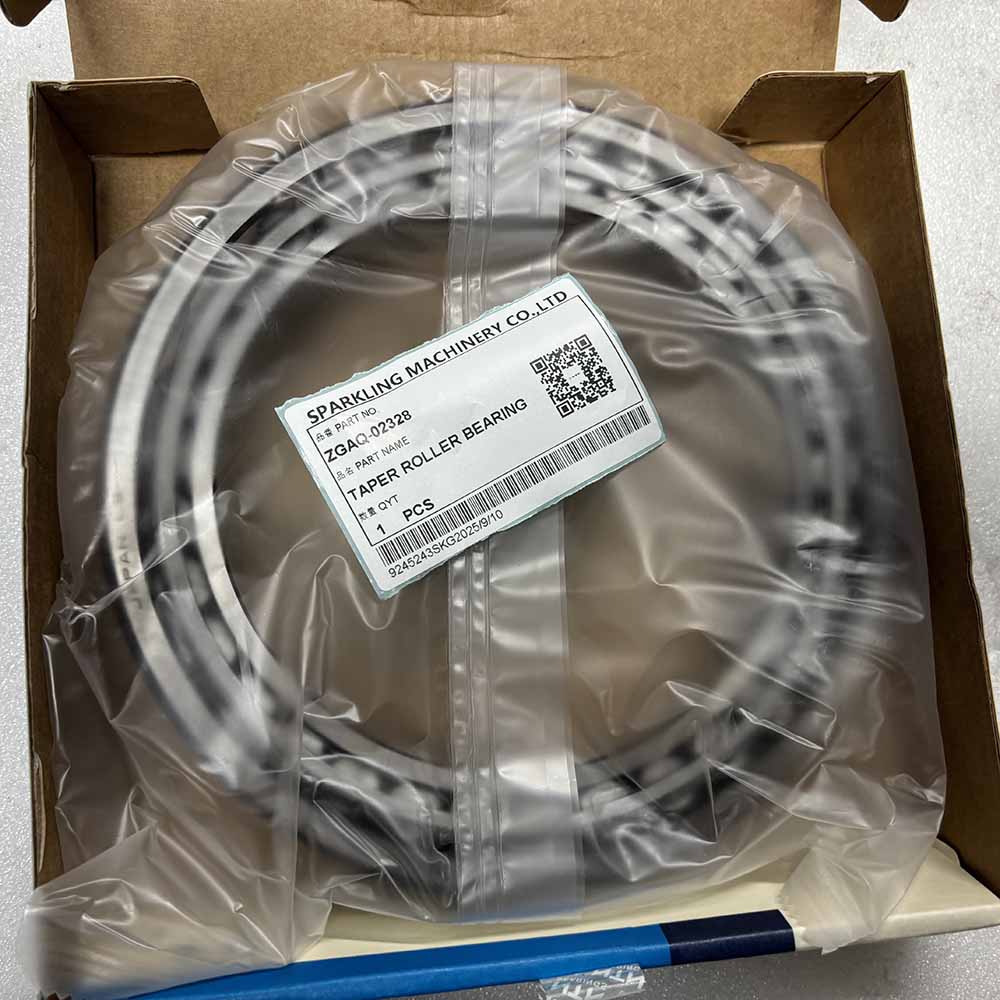

About the product: HYUNDAI EXCAVATOR PARTS HW210 R200W7 R200W7A R210W-9 ZGAQ-02328

SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing is a core rotating component for Hyundai excavators (construction/mining use). It withstands combined radial and axial loads, ensuring smooth rotation of key shaft parts.

Meeting Hyundai OEM standards (Part No.: ZGAQ-02328), it delivers high wear resistance and load capacity, guaranteeing seamless compatibility and long-term stable operational performance.

Interchangeability between R210W-9 and R200W7A

Interchangeability depends on the bearing seat dimensions, shaft journal diameter, housing width, and preload requirements. The ZGAQ-02328 is manufactured to match Hyundai OEM geometries for certain rotating assemblies in the HW210, R200W7, R200W7A and R210W-9 families. When evaluating interchangeability, always compare the following:

- OEM part number cross-reference and Hyundai parts catalog data

- Shaft journal diameter and shoulder locations

- Housing bore and retaining arrangement (locknut, snap ring, press fit)

- Required axial preload and ability to adjust via spacers or collars

Where direct OEM cross-reference exists (ZGAQ-02328), compatibility is usually assured for the intended bearing positions. However, confirm with the machine's parts manual or an official parts diagram before replacing bearings in critical systems.

Quick comparison table: suitability for common bearing locations

| Bearing Role | R210W-9 | R200W7A | ZGAQ-02328 Fit |

|---|---|---|---|

| Swing bearing interface (secondary) | Used in slew assemblies; large-diameter slew rings | Similar slew ring designs for wheeled models | Compatible where OEM specifies ZGAQ-02328 or matching geometry |

| Final drive input shaft | Moderate radial/axial loads; compact housings | Comparable layout; minor dimensional differences possible | Compatible if journal/housing dims match OEM spec |

| Steering/axle pivot shafts | Smaller tapered bearings or bushings often used | May differ by linkage; verify before use | Possible in some assemblies; verify cross-reference |

Installation, inspection and maintenance best practices

Pre-installation checks

Before fitting ZGAQ-02328 or any tapered roller bearing into an excavator assembly, perform these checks:

- Verify OEM part number or cross reference in the Hyundai parts manual.

- Measure shaft journal, housing bore, and width to confirm dimensional match.

- Inspect the shaft and housing for wear, scoring, or corrosion; repair or machine as required.

- Confirm lubrication type and grease/oil compatibility for the target application (swing gearbox vs final drive).

Correct installation techniques

Key points for installing tapered roller bearings:

- Cleanliness — keep parts and tools free from contaminants. Even small grit particles reduce bearing life.

- Assembly method — bearings should be pressed or driven evenly; do not hammer the rollers or race directly. Use proper pullers, presses, or fitting tools.

- Preload adjustment — tapered bearings require controlled axial displacement to set preload. Follow Hyundai service manual torque and axial play specifications. Incorrect preload can cause noise, heat, and early failure.

- Seals and retainers — replace seals and check retaining rings or locknuts for wear. Sealing integrity prevents ingress of dust and water common on construction sites.

Service intervals and monitoring

Regular monitoring extends bearing life:

- Inspect for heat, vibration, and unusual noise after 50–200 operating hours initially, then at scheduled service intervals.

- Check lubricant condition and level per gearbox/final drive recommendations. Contaminated lubricant is a primary failure cause.

- Record operating hours and replacement dates in a maintenance log to identify wear patterns related to operating environment.

Troubleshooting common bearing issues and repair choices

Symptoms and root causes

Common bearing-related symptoms and likely causes:

- Excessive heat — insufficient lubrication, contaminated grease/oil, or overload.

- Vibration and noise — misalignment, incorrect preload, damaged rollers/races, or gear tooth damage transmitting vibration.

- Rapid wear — abrasive contamination, poor sealing, improper installation, or shock loads beyond design.

When to replace vs rebuild

Decide based on inspection findings and cost/benefit:

- Replace bearing (e.g., ZGAQ-02328) if you find pitting, flaking, brinelling, fracture, or permanent deformation.

- Rebuild gearbox or hub if multiple components (gears, seals, shafts) are in good dimension but require bearing replacement and re-shimming.

- Always replace seals and check related fasteners during rebuilds to reduce repeat failures.

Case example: diagnosing a noisy final drive

Steps to diagnose:

- Listen and localize the noise (swing vs travel vs engine input).

- Check oil level and condition in the final drive. Metal particles indicate internal damage.

- Remove cover and inspect bearings, shafts, and gears for pitting or discoloration.

- If bearings show roller or race damage, replace with correct OEM or equivalent (such as ZGAQ-02328) and inspect mating components for scoring.

References and further reading

Industry guidance and standards to support bearing selection and life calculations include:

- Tapered roller bearing — Wikipedia

- Excavator — Wikipedia

- ISO 281 — Rolling bearings — Dynamic load ratings and rating life

- Association of Equipment Manufacturers (AEM) — industry trends and technical resources

FAQ

Q: Is ZGAQ-02328 a direct OEM replacement for both R210W-9 and R200W7A?

A: ZGAQ-02328 is manufactured to meet Hyundai OEM standards and is a direct replacement where Hyundai parts lists specify ZGAQ-02328 for the particular bearing position. Always confirm the parts diagram and part number for the exact assembly on your machine before ordering.

Q: How do I verify the right bearing dimensions for my machine?

A: Measure the shaft journal diameter, housing bore, and axial space where the bearing sits. Cross-check those measurements with the OEM parts manual or the supplier’s dimensional sheet. If available, use the Hyundai parts catalog or service manual for model-specific dimensions.

Q: Can I reuse old spacers or seals when fitting a new ZGAQ-02328 bearing?

A: It is best practice to replace seals and critical spacers that set bearing preload. Reusing worn seals or spacers can allow contamination or lead to incorrect preload and premature failure.

Q: What lubrication should I use for this tapered roller bearing?

A: Lubrication varies by application (closed final drive vs open carrier housing). Use the lubricant type and grade recommended by Hyundai for the specific assembly. For general guidance on lubricants and bearing life, consult industry references such as ISO lubrication recommendations and the machine’s service manual.

Q: How quickly will bearing failure spread to other components?

A: Bearing failure can accelerate damage to adjacent gears, shafts, and seals. Metal debris from a failed bearing circulates through gearboxes and can score gears and bearings, so immediate inspection and replacement after suspected failure are critical to prevent cascading damage.

If you need the exact OEM cross-reference, installation instructions, or a quote for HYUNDAI EXCAVATOR PARTS HW210 R200W7 R200W7A R210W-9 ZGAQ-02328 TAPER ROLLER BEARING SPARKLING MACHINERY, contact our parts team or view the product page for specifications and availability.

Contact us: For technical support, compatibility confirmation, or to order, please contact our parts specialists or visit the product listing to check stock and pricing.

2026 Cost Breakdown of Hydraulic System Components

Choosing the Right Excavator Parts Supplier: What to Ask

Hydraulic Fluid and Filters: Best Practices 2026

The B2B Buyer’s Guide to Hydraulic Systems for Excavators | SPARKLING Ultimate Insights

faq

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

K5V212DPH1J8R-9NG4-AV Hydraulic Pump - Construction Machinery Spare Parts fits EC300D EC350D EC380D R335LC-9V

The K5V212DPH1J8R-9NG4-AV is an OEM-compatible variable displacement axial piston main hydraulic pump, custom-engineered for Volvo EC300D/EC350D/EC380D and Hyundai R335LC-9V 30-38 ton excavators.

Key Features

· High-power output: 212cc displacement, max pressure 34.3 MPa, 1800 rpm rated speed—matches 150-190kW engine power for 30-38 ton excavators, ensuring efficient high-load operation.

· Precision flow control: Electro-hydraulic proportional control adjusts output per workload, cutting fuel consumption by 8% vs. standard pumps while maintaining smooth actuator response.

· Direct OEM fit: Exact mounting points, hydraulic ports, and SAE J518 flanges enable plug-and-play installation without system reconfiguration or adapter parts.

· Durable components: Hardened cylinder block, chrome-plated pistons, and wear-resistant valve plate extend service life; integrated pressure relief valve prevents overload damage.

Compatible Models & Part Numbers

· Volvo Excavators: EC300D, EC350D, EC380D

· Hyundai Excavators: R335LC-9V

· Part Number: K5V212DPH1J8R-9NG4-AV

· Interchangeable References: K5V212DPH-9N series; matches original main pump specs for above models

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879