Choosing the Right Excavator Parts Supplier: What to Ask

- Choosing the Right Excavator Parts Supplier: What to Ask

- Why choosing the right supplier for excavator parts matters

- Key supplier credentials and certifications to verify

- Questions about part quality and compatibility

- Inventory, lead times and emergency support

- Pricing, payment terms and total cost of ownership

- Warranties, returns and after-sales support

- Logistics, packaging and customs compliance

- Technical documentation and traceability

- Specific questions for Hyundai-compatible components and the SPARKLING MACHINERY hub

- Comparing OEM, aftermarket and remanufactured excavator parts

- Red flags when evaluating excavator parts suppliers

- Brand advantages: Why consider SPARKLING MACHINERY for Hyundai-compatible hubs

- Practical checklist: What to ask a potential excavator parts supplier today

- Frequently Asked Questions (FAQ)

- Q: How do I verify that a Hyundai-compatible hub will fit my machine?

- Q: Are aftermarket Chinese-made excavator parts reliable?

- Q: What is a reasonable warranty for a hub or undercarriage component?

- Q: How do I minimize downtime when replacing a failed hub?

- Q: Can SPARKLING MACHINERY parts be considered OEM?

- Contact us / View product

- Sources

Choosing the Right Excavator Parts Supplier: What to Ask

Why choosing the right supplier for excavator parts matters

Selecting the right supplier for excavator parts is not only a procurement decision — it affects machine uptime, safety, operating costs and project schedules. Poor-quality parts or unreliable supply chains can lead to unexpected downtime, higher total cost of ownership, and compromised safety. When you’re buying critical components such as hubs, final drives, hydraulic pumps or undercarriage parts, asking the right questions up front helps you assess risk and make an informed choice.

Key supplier credentials and certifications to verify

Before getting into technical details, verify the supplier’s credentials. Ask for documentation and check these items:

- Business license and registration in their operating jurisdiction.

- OEM authorizations or franchise agreements if they claim genuine parts.

- ISO 9001 or equivalent quality management certification (confirms consistent processes).

- Traceability systems for part batches and serial numbers.

These credentials confirm the supplier’s legitimacy and their commitment to quality management. For excavator parts, traceability is particularly important if you need to validate compatibility with specific machine serial numbers or warranty claims.

Questions about part quality and compatibility

Quality and compatibility are the top priorities when sourcing excavator parts. Use these targeted questions to evaluate a supplier:

- Is this part OEM, aftermarket, or remanufactured? (Ask for documentation.)

- Can you provide part numbers, drawings, and compatibility lists for specific machine models and serial ranges?

- Are parts manufactured to OEM tolerances and material specifications?

- Do you perform incoming inspection and functional testing? Can you share test reports?

- What temperature, wear, and impact specifications does the part meet?

Example: For Hyundai excavator hubs, confirm OEM cross-reference codes. The SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub states compatibility with Hyundai R160W9A/R170W7/R170W7A/R170W9 and claims to meet ZGAQ-03591 standards and resist -30°C to 100°C temperatures. Ask the supplier to supply test data or a certificate of conformity to validate these claims.

Inventory, lead times and emergency support

Downtime costs money. Assess a supplier’s inventory and responsiveness by asking:

- What is your stock level for critical excavator parts? Can you provide an inventory list?

- What are typical lead times for stocked items versus special orders?

- Do you offer expedited shipping or emergency shipments for breakdowns?

- Can you provide consignment stock or AOG (air on ground) support for key customers?

Reliable suppliers will be transparent about stock and able to provide realistic lead times. If they cannot support emergency shipments, you should factor that into your contingency planning or choose a supplier with faster logistics capabilities.

Pricing, payment terms and total cost of ownership

Price is important but must be evaluated alongside quality, warranty and lifecycle costs. Ask:

- Is the quoted price for a single unit or a minimum order quantity (MOQ)?

- What payment methods and credit terms do you offer?

- Do you offer volume discounts or long-term contract pricing?

- Can you provide a lifecycle cost comparison (initial price, expected life, warranty, service costs)?

A lower unit price can be attractive but might hide higher long-term costs if parts fail sooner or cause additional wear on connected assemblies. Request expected service life data and failure rates if available.

Warranties, returns and after-sales support

Good after-sales support reduces your risk. Questions to ask include:

- What warranty do you provide for this part (period and coverage)?

- What is your returns process for defective or non-compatible parts?

- Do you offer technical support for installation, troubleshooting or testing?

- Are spare or repair kits available, and what's their lead time?

For example, a supplier who offers installation guides, torque specs and phone support for component troubleshooting adds tangible value — especially for complex parts like hubs and final drives.

Logistics, packaging and customs compliance

Shipping heavy or precision excavator parts requires care. Ask your supplier:

- How are parts packaged to prevent damage in transit?

- Which carriers and incoterms (EXW, FOB, CIF, DDP) do you use?

- Can you provide HS codes, commercial invoices and packing lists for customs clearance?

- Do you assist with export/import documentation and duties?

Correct packaging and clear documentation reduce delays at customs and the risk of transit damage. Confirming incoterms clarifies who bears the shipping and insurance risk.

Technical documentation and traceability

Ask for the technical resources you’ll need to install and maintain parts:

- Installation instructions, torque values and alignment procedures.

- Material certificates and heat-treatment records where applicable.

- Batch and serial number traceability for recall or warranty management.

- Service and maintenance schedules to maximize part life.

Traceability lets you link a failed component back to its production batch — essential for root-cause analysis and warranty recovery.

Specific questions for Hyundai-compatible components and the SPARKLING MACHINERY hub

When sourcing parts that must mate with a specific machine family (such as Hyundai R160W9A/R170W7/R170W7A/R170W9), include model-specific checks:

- Does the part match the exact Hyundai OEM part number or cross-reference? (e.g., ZGAQ-03591).

- Has the part been tested on machines in the same series or serial-number range?

- Can you provide dimensional drawings and material specifications for the hub?

- Does the hub resist the operational temperature and load ranges of the machine?

Below is the supplied product description for reference:

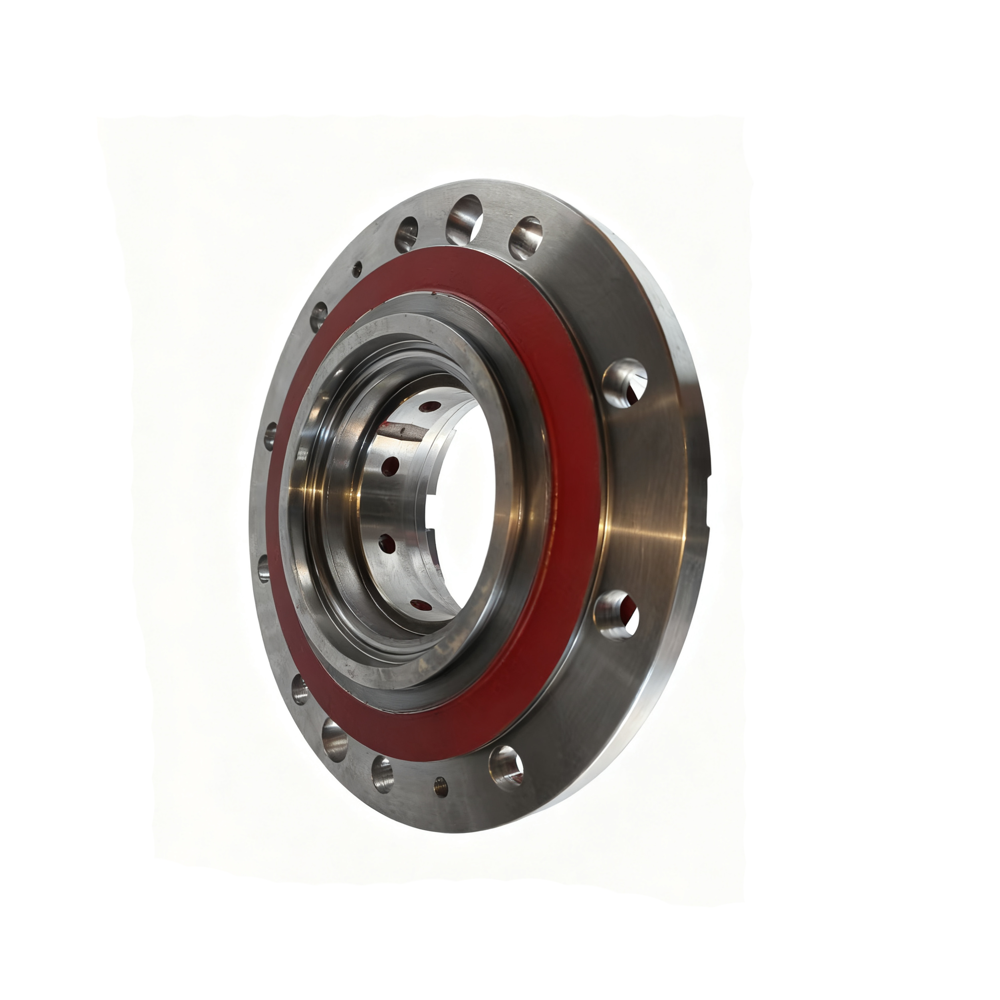

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

Ask your supplier for test certificates proving resistance to the stated temperature range and for material hardness/wear test results. If the supplier is exporting from China, confirm production site audits and any third-party inspection reports.

Comparing OEM, aftermarket and remanufactured excavator parts

Choosing between OEM, aftermarket and remanufactured parts requires balancing cost, availability and risk. The table below summarizes typical differences:

| Attribute | OEM | Aftermarket (high-quality) | Remanufactured |

|---|---|---|---|

| Fit & Compatibility | Guaranteed by manufacturer | Often compatible; verify fit | Depends on reman process |

| Price | Highest | Lower | Lower–medium |

| Warranty | Standard OEM warranty | Varies; check terms | Typically limited warranty |

| Availability | May have long lead times | Often better stock levels | Depends on inventory |

Source references for this comparison include OEM and aftermarket industry guidance (see Sources).

Red flags when evaluating excavator parts suppliers

Watch for these warning signs:

- Reluctance to provide certifications, test reports, or part drawings.

- Unclear or changing delivery promises without written confirmation.

- No documented warranty or a returns policy that heavily favors the supplier.

- Extremely low prices with vague origin claims — could indicate counterfeit parts.

If you see these red flags, pause procurement until you have verifiable proof of quality and traceability.

Brand advantages: Why consider SPARKLING MACHINERY for Hyundai-compatible hubs

When evaluating suppliers of Hyundai-compatible undercarriage components, SPARKLING MACHINERY offers several advantages you should confirm:

- Model-specific production: The SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is produced specifically for Hyundai R160W9A/R170W7/R170W7A/R170W9 series, which simplifies compatibility verification.

- Claims to meet OEM standard ZGAQ-03591 and specified temperature and wear resistance, which reduces the risk of early failure in heavy-duty use.

- Manufacturing origin in China with potential cost advantages and scalable production capacity — relevant when buying multiple units for fleet maintenance.

- When combined with supplier-provided test reports, warranty and technical support, such parts can deliver strong value compared to costly OEM lead times.

Always ask SPARKLING MACHINERY (or any seller) for certificates, batch traceability, and third-party inspection reports to validate these claimed advantages.

Practical checklist: What to ask a potential excavator parts supplier today

Use this checklist during supplier calls or RFQs:

- Exact part number and cross-reference to OEM (e.g., ZGAQ-03591).

- Availability: stock quantity, lead time for additional units.

- Quality evidence: ISO certificates, material reports, test certificates.

- Warranty terms and returns policy.

- Packaging, shipping method, incoterms, and customs support.

- Price, MOQ, payment terms and any applicable discounts.

- Technical support availability and installation guidance.

Frequently Asked Questions (FAQ)

Q: How do I verify that a Hyundai-compatible hub will fit my machine?

A: Ask the supplier for the exact OEM part number cross-reference (e.g., ZGAQ-03591), dimensional drawings, and a compatibility list that includes your machine model and serial number range. If possible, request a sample for a test-fit or ask for photos showing the hub fitted to the intended axle assembly.

Q: Are aftermarket Chinese-made excavator parts reliable?

A: Many Chinese manufacturers produce high-quality parts that meet OEM standards, but quality varies. Verify ISO certifications, conduct factory audits if possible, request third-party inspection reports, and evaluate warranty and after-sales support before purchasing in volume.

Q: What is a reasonable warranty for a hub or undercarriage component?

A: Warranty periods vary by supplier and part type. For load-bearing undercarriage components, a 6–12 month warranty or a specified operating-hours warranty (e.g., 1,000–2,000 hours) with coverage for manufacturing defects is common. Confirm specifics in the contract.

Q: How do I minimize downtime when replacing a failed hub?

A: Maintain a small stock of critical components, work with suppliers who offer expedited shipping or consignment stock near major depots, and ensure technicians have installation instructions and torque specs on hand. Preventive inspections and condition monitoring reduce unexpected failures.

Q: Can SPARKLING MACHINERY parts be considered OEM?

A: Unless explicitly authorized by the OEM (Hyundai), SPARKLING MACHINERY parts are aftermarket components designed to meet OEM standards (per supplier claims). Always request documentation proving conformity to the cited OEM standard (ZGAQ-03591) if OEM equivalence is required.

Contact us / View product

If you need more details, test certificates, or a formal quote for the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub, contact our sales team. We can provide compatibility verification, lead times, pricing, and inspection reports on request. Email: sales@example.com | Phone: +1-555-0123 | View product page: https://example.com/products/sparkling-r160w9a-hub Selecting the right supplier is just the beginning; Hyundai R170W7 parts are designed to significantly improve your machine’s performance. Understanding the impact of these parts on your excavator’s operations will help you make the best investment for your equipment’s future.

Sources

- ISO 9001: Quality management systems — International Organization for Standardization. https://www.iso.org/iso-9001-quality-management.

- OEM parts and maintenance guidance from major manufacturers (e.g., Hyundai Construction Equipment information pages and parts catalogs). https://www.hyundai-ce.com

- Industry guidance on aftermarket vs OEM parts: Caterpillar and industry aftermarket whitepapers. https://www.cat.com

- Export/import documentation and incoterms overview: International Chamber of Commerce (ICC) Incoterms. https://iccwbo.org/resources-for-business/incoterms-rules/

Choosing the Right Hydraulic Pump for Your Excavator Model

Guide to Hydraulic Parts of Excavator for Maintenance 2026

Long-Term Care Tips for Hyundai Excavator Components

The B2B Buyer’s Guide to Excavator Undercarriage Parts

faq

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879