Benefits of VOE14558962 Brake Disc for Volvo EW160/EW180

- Benefits of VOE14558962 Brake Disc for Volvo EW160/EW180

- Overview: What is the VOE14558962 brake disc?

- Key safety benefits of the brake disc for Volvo EW160 and EW180

- Durability and material performance: wear, corrosion and temperature resistance

- Compatibility and OEM standard assurance for EW160C/D/E and EW180C/D models

- Operational benefits: on-road, municipal, and yard operations

- Maintenance guidance and replacement best practices

- Installation checklist for technicians

- Performance comparison: VOE14558962 vs generic aftermarket and low-quality copies

- How the brake disc improves total cost of ownership (TCO)

- Brand advantages: Why choose SPARKLING MACHINERY VOLVO EXCAVATOR PARTS MADE IN CHINA NEW ... VOE14558962

- Frequently Asked Questions (FAQ)

- Q1: Is VOE14558962 an original Volvo part?

- Q2: Will installing VOE14558962 affect ABS or machine electronics?

- Q3: How often should the brake disc be inspected or replaced?

- Q4: What signs indicate the disc is failing?

- Q5: Does the part come with warranty or certification?

- Q6: Can I replace the disc myself?

- Contact & Purchase: View product or speak to a specialist

- Authoritative references and further reading

Benefits of VOE14558962 Brake Disc for Volvo EW160/EW180

Overview: What is the VOE14558962 brake disc?

SPARKLING MACHINERY NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 Disc Brake is a dedicated safety component for VOLVO EW160C/EW160D/EW160E/EW180C/EW180D wheeled excavators (used in road construction, municipal engineering, and material handling). As the core of the braking system, it provides stable stopping force to ensure safe on-road travel and off-road operation, preventing accidents during tasks like loading or navigating uneven terrain.

Meeting VOLVO OEM standards (part no. VOE14558962), it endures high friction, -30°C to 90°C temperatures, and vibration. It resists wear and corrosion, ensuring long-term braking reliability for the five VOLVO models, with strict testing guaranteeing compatibility and safe performance.

Key safety benefits of the brake disc for Volvo EW160 and EW180

The primary role of any brake disc is safety. For the VOE14558962 brake disc installed on Volvo EW160 and EW180 wheeled excavators, safety advantages include reliable stopping power under load, predictable braking feel during repeated cycles, and consistent performance across variable working conditions (paved roads, construction sites, curbs, and material handling zones). Because wheeled excavators operate both on roads and in confined job sites, the brake disc’s stable friction behavior helps prevent runaways, reduces the risk of load shift during braking, and supports driver confidence when maneuvering around people and equipment.

Durability and material performance: wear, corrosion and temperature resistance

Excavator brake discs are exposed to heavy loads, frequent temperature cycles, and contaminants like dust, water, and salt. The VOE14558962 disc is engineered to meet these demands: it resists surface wear, maintains structural integrity under vibration, and tolerates temperatures from -30°C to 90°C. These properties reduce the risk of warping, cracking, or uneven wear that can create vibration, noise, or loss of braking efficiency. For fleet operators, longer disc life means fewer replacements, less downtime, and lower total cost of ownership.

Compatibility and OEM standard assurance for EW160C/D/E and EW180C/D models

Compatibility is critical for braking components. The VOE14558962 is manufactured to meet Volvo OEM fit and function for EW160C, EW160D, EW160E, EW180C and EW180D wheeled excavators. OEM-standard components ensure proper fit on hubs, correct centering and run-out tolerances, and compatibility with factory caliper geometry. This minimizes installation adjustments and guarantees that braking balance and ABS/sensor interactions (if applicable) remain within Volvo-designed parameters. Using an OEM-equivalent part reduces the risk of unexpected failures caused by poor fit or material mismatch.

Operational benefits: on-road, municipal, and yard operations

Wheeled excavators like EW160/EW180 perform a mix of duties: travel on public roads between sites, perform municipal tasks (e.g., digging and backfilling near utilities), and handle materials in yards. The VOE14558962 disc is optimized for this mixed use. Benefits include:

- Consistent deceleration and short stopping distances under varied load conditions;

- Stable performance during frequent stop-start cycles common in municipal work;

- Resistance to performance degradation when exposed to water or contaminants during yard duties;

- Reduced brake noise and vibration, improving operator comfort and equipment lifespans.

Maintenance guidance and replacement best practices

Proper maintenance preserves brake performance and extends service life. For the VOE14558962 brake disc, recommended practices include:

- Routine visual inspections every 50–250 operating hours: check for scoring, cracks, corrosion and uneven wear.

- Measure disc thickness and compare to Volvo service limits or the part supplier’s specification; replace when approaching minimum thickness.

- Inspect calipers, pads or shoes, hub bearings and hardware for contamination and proper torque.

- Clean mating surfaces and ensure proper run-out during installation to avoid vibration and uneven pad wear.

- Use correct pad materials and avoid mixing pad compounds that can change friction characteristics.

Installation checklist for technicians

To ensure correct fitment and performance:

- Verify part number VOE14558962 and compatibility with machine VIN or model plate.

- Inspect hub and mounting surface for rust, burrs or contamination; clean thoroughly.

- Measure disc run-out; confirm within manufacturer tolerance before tightening to final torque.

- Replace pads/shoes when installing a new disc to avoid uneven mating surfaces.

- Tighten fasteners to specified torque and perform a brake function test under controlled, safe conditions.

Performance comparison: VOE14558962 vs generic aftermarket and low-quality copies

The following table summarizes typical differences fleet managers should consider when choosing a brake disc for Volvo EW160/EW180 machines.

| Criteria | VOE14558962 (SPARKLING MACHINERY OEM-equivalent) | Generic Aftermarket | Low-quality Copy |

|---|---|---|---|

| Model compatibility | High — designed for EW160C/D/E & EW180C/D | Medium — may require adjustments | Low — risk of poor fit |

| Temperature tolerance | -30°C to 90°C (specified) | Variable — often narrower | Poor — higher risk of warping |

| Wear & corrosion resistance | High — treated materials/coating | Medium — depends on supplier | Low — premature corrosion |

| Testing & quality assurance | Strict testing to OEM standards | Limited | Minimal/none |

| Cost of ownership | Lower (longer life, less downtime) | Moderate | Higher (frequent replacements) |

How the brake disc improves total cost of ownership (TCO)

While initial purchase price matters, the VOE14558962 brake disc reduces TCO in several ways:

- Longer service life reduces parts consumption and replacement labor;

- Reliable braking lowers accident risk and associated repair downtime and liability;

- OEM-equivalent fit reduces installation time and avoids rework;

- Better corrosion resistance keeps the disc in service longer in harsh environments.

Brand advantages: Why choose SPARKLING MACHINERY VOLVO EXCAVATOR PARTS MADE IN CHINA NEW ... VOE14558962

SPARKLING MACHINERY positions the VOE14558962 disc as an OEM-equivalent part made to Volvo specifications. Brand advantages include:

- Dedicated focus on VOLVO wheeled excavator parts ensuring model-specific fit;

- Manufacturing to OEM standards and pre-shipment testing to ensure compatibility and safety;

- Competitive sourcing and logistics (made in China) with quality control to meet international standards;

- After-sales support and technical guidance for installation and maintenance.

Frequently Asked Questions (FAQ)

Q1: Is VOE14558962 an original Volvo part?

A1: VOE14558962 is a Volvo OEM part number. The SPARKLING MACHINERY product is described as an OEM-equivalent that meets Volvo standards for EW160C/D/E and EW180C/D machines. Verify part numbers and supplier documentation when ordering to confirm authenticity.

Q2: Will installing VOE14558962 affect ABS or machine electronics?

A2: The disc itself is a mechanical component. When fitted to correct Volvo models and installed per procedure, it maintains original braking geometry and should not adversely affect ABS or related systems. Ensure sensors and wiring are inspected during installation.

Q3: How often should the brake disc be inspected or replaced?

A3: Inspect discs during routine maintenance intervals (commonly every 50–250 hours depending on use). Replace when disc thickness approaches the minimum specification, if there are cracks, deep scoring, or significant run-out. Exact replacement intervals vary with operating conditions.

Q4: What signs indicate the disc is failing?

A4: Common signs include increased stopping distance, vibration or pulsation during braking, visible cracks or heavy scoring, uneven pad wear, and excessive corrosion at the friction surface. Any of these warrant immediate inspection and likely replacement.

Q5: Does the part come with warranty or certification?

A5: Warranty and certification depend on the supplier and purchase agreement. SPARKLING MACHINERY states the part meets OEM standards and undergoes strict testing. Confirm warranty terms and any certification documentation (material test reports, dimensional inspection) at time of sale.

Q6: Can I replace the disc myself?

A6: Technically yes if you have the right tools, torque specs, and mechanical experience. However, correct installation and run-out checks are critical. For fleets, using trained technicians or authorized service centers is recommended to ensure safety and maintain warranty coverage.

Contact & Purchase: View product or speak to a specialist

To fully realize these benefits, it is essential to know how to spec brake discs for Volvo EW160/EW180 based on operating conditions and machine load.If you are interested in ordering VOE14558962 or need technical assistance selecting the correct brake disc for your Volvo EW160/EW180 machines, contact our sales team or request a quote. We provide product datasheets, compatibility verification by machine serial number, and guidance on installation and maintenance. Click to view product or contact us for a quote and lead time.

Authoritative references and further reading

Below are reputable sources for background on brakes, Volvo construction equipment and parts management:

- Brake (Wikipedia): https://en.wikipedia.org/wiki/Brake

- Volvo Construction Equipment (official): https://www.volvoce.com/

- Volvo Group Parts & Services overview: https://www.volvogroup.com/

- General vehicle braking systems guidance (SAE International): https://www.sae.org/

For part-specific certification, test reports, and warranty information, request documentation from the supplier at time of purchase.

Note: Product compatibility and specifications should be confirmed with the machine's serial number (VIN) and the supplier's technical team before purchase and installation.

How Taper Roller Bearings Impact Excavator Performance

Guide to R170W7 Excavator Parts and Key Components

Best professional excavator parts manufacturers and supplier brands

Hydraulic Fluid and Filters: Best Practices 2026

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

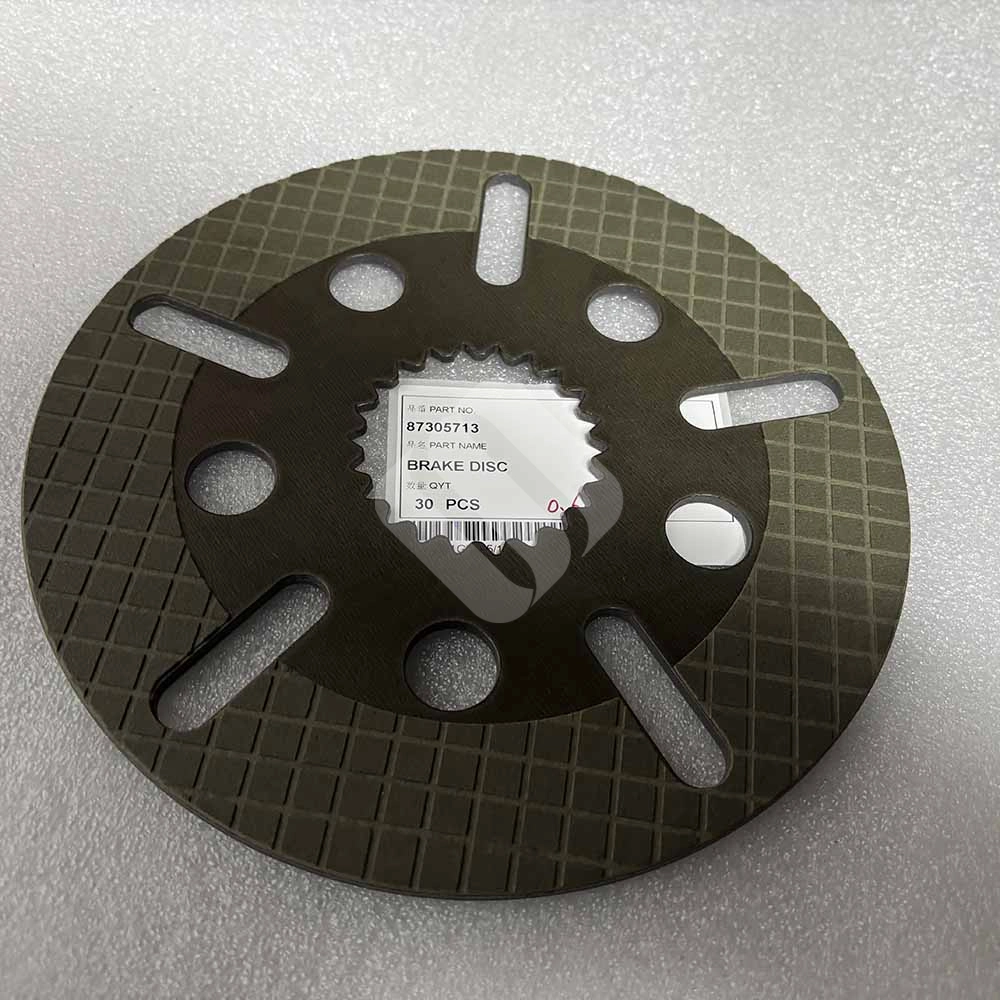

VOLVO HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B110B B100B LB90.B B90B B95B 87305713 BRAKE DISC SPARKLING MACHINERY

SPARKLING MACHINERY NEW B110B B100B LB90.B B90B B95B 87305713 Brake Disc is a core braking component for Volvo B110B/B100B/LB90.B/B90B/B95B excavators (heavy-duty construction/mining use). It works with brake pads to generate friction, ensuring reliable stopping and operational safety.

Meeting Volvo OEM standards (87305713), it resists -30°C to 300°C temps, wear, and thermal deformation, ensuring seamless compatibility and long-term reliable braking performance.

New Holland Backhoe Loaders 87305713 83959970 47123297 Brake Disc

87305713 is a specific industrial part number for a Brake Disc (or Friction Plate) used in agricultural and construction machinery, primarily manufactured by New Holland.

1.This friction disc is designed for oil-immersed (wet) braking systems. It is commonly found in:

New Holland Backhoe Loaders: Models including B90B, B100B, B110B, B115B, LB75, LB90, LB110, and LB115.

Ford Tractors: Series 550, 555, and 655.

Case IH: Certain models sharing the same drivetrain components

2. Technical Specifications

Outside Diameter (OD): ~204.75 mm

Inside Diameter (ID): ~55.88 mm (spline area)

Thickness: 4.8 mm

Teeth Count: 22 Teeth

Material: Paper-based friction material with a waffle-groove pattern for oil circulation and cooling

3. Cross-Reference Numbers

This part is often interchangeable with the following OEM and aftermarket numbers:

CNH: 83959970, 47123297

Ford/NH Original: E6NN2A097BB

Hyundai Wheel Loaders HL730-9 HL730-9A HL730-9S ZGAQ-03450 0501.323.355 DISC-INNER CLUTCH CHINA MADE

Part numbers 0501.323.355 (a ZF part number) and ZGAQ-03450 (a Hyundai part number) both refer to a Friction Disc used in the brake or clutch assembly of heavy machinery transmissions and axles.

This component is an inner clutch or brake friction plate/disc. It is a critical wear item within the drivetrain assembly (likely a ZF axle or transmission) responsible for creating the necessary friction to engage clutches or apply brakes in heavy equipment.

Compatible Equipment

This friction disc is commonly used in Hyundai wheel loaders and other construction equipment that utilize compatible ZF axles:

Hyundai Wheel Loaders: HL730-9, HL730-9A, HL730-9S, HL730TM-9A.

Other Compatible Equipment: Various backhoe loaders, including certain models by John Deere (e.g., 310, 315, 210K, 310SJ, 325K)

Part Numbers: 0501.323.355, 0501323355, ZGAQ-03450, ZGAQ03450, AT339543, 482-6743, VOE 15071853, S06/42932

ZTAM-00615 Support Kit Compatible with Hyundai R140W-7 & R140W-7A Wheel Excavators

ZTAM-00615 is an OEM-compatible support kit for Hyundai R140W-7/R140W-7A excavators. It provides essential structural reinforcement and vibration damping for key components, ensuring reliable performance under heavy loads and harsh working conditions in construction and engineering applications.

Key Features

· OEM direct‑fit design: Exact matching of mounting positions, hole spacing, and geometric dimensions for Hyundai R140W‑7 / R140W‑7A — plug‑and‑play without modification.

· High‑strength structural support: Heavy‑duty steel construction with reinforced stress points for excellent load capacity and impact resistance.

· Stable & durable: Anti‑wear, anti‑deformation, and anti‑corrosion surface treatment for long service life in harsh environments.

Compatible Models: Hyundai Wheel Excavators R140W-7, R140W-7A

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879