Top Signs Your Excavator Needs a Hub Replacement

- Top Signs Your Excavator Needs a Hub Replacement

- Why the Excavator Hub Matters for Excavator Parts and Machine Reliability

- Common Causes of Hub Failure in Excavator Parts

- Sign 1 — Excessive Play or Lateral Movement in the Wheel/Hub Assembly

- Sign 2 — Grinding, Clicking, or Roaring Noises During Travel

- Sign 3 — Uneven Track or Tire Wear and Misalignment

- Sign 4 — Visible Oil Leaks or Seal Failure at the Hub

- Sign 5 — Hub Overheating or Hot to the Touch After Operation

- Sign 6 — Vibration Felt Through the Frame or Controls

- Sign 7 — Visible Cracks, Distortion, or Surface Damage

- Quick Reference: Symptom Severity and Recommended Actions

- How to Inspect a Hub Safely — Practical Steps

- Choosing the Right Replacement: OEM vs Aftermarket Excavator Parts

- Product Highlight: Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 HUB SPARKLING MACHINERY

- Installation Tips and Best Practices for Excavator Parts Replacement

- Brand Advantages — Why SPARKLING MACHINERY Hubs Are a Strong Option

- Frequently Asked Questions (FAQ)

- Q: How long should a hub last under normal use?

- Q: Can I rebuild a damaged hub or must it be replaced?

- Q: Is the SPARKLING MACHINERY ZGAQ-03591 hub compatible with my Hyundai R170W7 excavator?

- Q: What routine checks prevent unexpected hub failures?

- Q: Do aftermarket hubs void the machine warranty?

- Contact Us / View the Product

- References

Top Signs Your Excavator Needs a Hub Replacement

Why the Excavator Hub Matters for Excavator Parts and Machine Reliability

The wheel hub (or track carrier hub on wheeled excavators and carrier/mid roller hubs on tracked machines) is a critical excavator parts component that links the track system or wheel assembly to the axle. It takes heavy vertical and lateral loads, transfers torque during travel, and seals lubrication for bearings and internal gears. When a hub begins to fail, the consequences range from reduced performance and increased fuel use to catastrophic breakdowns and costly downtime. For owners and fleet managers, recognizing the early warning signs of hub failure is essential. If you're facing issues with your hub, it's essential to know how to choose the right excavator parts supplier. The supplier you select plays a significant role in ensuring you receive high-quality replacement parts, so asking the right questions is crucial in making an informed decision.

Common Causes of Hub Failure in Excavator Parts

Understanding why hubs fail helps you prioritize inspections and fixes. The most common causes are:

- Wear and fatigue from heavy, repeated loading (common in construction and mining)

- Insufficient lubrication or contaminated lubricant leading to bearing failure

- Impact damage from debris, rock strikes, or collisions

- Seal failure allowing water and dirt ingress

- Corrosion from harsh environments or chemical exposure

- Poor installation or use of substandard replacement parts

All of the above relate directly to quality of excavator parts and maintenance practices; selecting hubs manufactured to OEM standards and following a disciplined inspection routine reduces risk.

Sign 1 — Excessive Play or Lateral Movement in the Wheel/Hub Assembly

How it presents: With the machine safely lifted and wheels or track carriers unloaded, you can rock the wheel or carrier back and forth. If you detect noticeable side-to-side play at the hub (beyond OEM-specified tolerances), that indicates bearing wear or internal damage to hub bores and interfaces.

Why it matters: Excessive play accelerates track and sprocket wear, causes misalignment, and can lead to bearing failure or axle damage. This quickly becomes an expensive repair if ignored.

Action: Immediate inspection. If play is present, remove hub cover and inspect bearings and seals. For wheel-hub systems, measure runout and bearing clearances to confirm diagnosis.

Sign 2 — Grinding, Clicking, or Roaring Noises During Travel

How it presents: Abnormal noises — grinding, metallic clicking, or a low roar — that change with speed or loading are a classic sign of internal bearing damage or gear tooth wear within the hub assembly.

Why it matters: Noises usually mean components are already damaged and running metal-on-metal. Continuing operation increases damage rapidly and can produce secondary failures (seized hubs, broken axles).

Action: Stop operation and perform a thorough inspection. Replace worn bearings and check for gear/hub surface damage. If noise source is the hub, prepare for hub replacement to avoid further downtime.

Sign 3 — Uneven Track or Tire Wear and Misalignment

How it presents: You notice one side of the track or tire wearing faster, cupping, or showing abnormal shoulder wear. Tracks may pull to one side during travel.

Why it matters: Hub wear or a damaged hub flange changes geometry and wheel offset. Misalignment increases rolling resistance, fuel use, and stresses other undercarriage excavator parts.

Action: Check axle alignment and hub mounting surfaces. If hub face or bearing bores are out of tolerance, replacement is the reliable fix rather than repeated alignments.

Sign 4 — Visible Oil Leaks or Seal Failure at the Hub

How it presents: Grease or oil present on the outer hub surface, drips from hub cover seals, or contaminated lubricant sampled from the hub cavity.

Why it matters: Leaking seals allow dirt and water into the bearing cavity. Contaminated grease rapidly destroys bearings and corrodes internal parts. A leaking hub is a high-risk condition for complete bearing failure.

Action: Replace hub seals or the full hub assembly depending on contamination extent. After replacement, flush and refill with correct lubricant and monitor regularly.

Sign 5 — Hub Overheating or Hot to the Touch After Operation

How it presents: After a short operating period, the hub surface becomes abnormally hot compared to other running gear. Temperature rise may be gradual but marked.

Why it matters: Excess heat indicates friction inside the hub — usually due to bearing failure, lack of lubricant, or binding of internal components. Heat shortens component life and can lead to lubricant breakdown or fire risks in extreme cases.

Action: Stop and allow cooling, then inspect lubrication and bearing condition. Replace hub if bearings are scored or internal clearances are compromised.

Sign 6 — Vibration Felt Through the Frame or Controls

How it presents: Operators report vibration or shudder when moving, excavating or swinging. Vibration may intensify with speed and load.

Why it matters: Imbalances or unevenness inside the hub (damaged bearing rollers, worn races, or cracked hub structure) transmit vibration. Vibration reduces operator comfort, damages attachments, and shortens component life across excavator parts.

Action: Diagnose the source with runout checks and bearing inspection. Replace the hub if internal damage is confirmed.

Sign 7 — Visible Cracks, Distortion, or Surface Damage

How it presents: Visual inspection reveals cracks, gouges, fractured bolt holes, or severe corrosion on the hub body.

Why it matters: Structural damage compromises load-bearing capacity. Cracks propagate under load and can cause sudden catastrophic failure.

Action: Replace the hub immediately. Do not operate with structural damage.

Quick Reference: Symptom Severity and Recommended Actions

| Symptom | Typical Severity | Recommended Action |

|---|---|---|

| Excessive play | Medium to High | Inspect bearings; likely hub replacement |

| Grinding noises | High | Stop and replace bearings/hub |

| Uneven wear | Medium | Check alignment; repair or replace hub |

| Oil leaks | Medium to High | Replace seals/hub and clean lubricant |

| Overheating | High | Immediate inspection; likely replacement |

| Visible cracks | Critical | Replace hub immediately |

Note: Severity guidance is based on standard industry maintenance practices and manufacturer recommendations. (See References.)

How to Inspect a Hub Safely — Practical Steps

Follow these steps to perform a basic hub inspection. Always follow machine-specific safety procedures and lockout/tagout.

- Park on level ground, lower attachments, shut down, and secure the machine.

- Raise the machine safely (jack stands or hoist) to unload the wheel/track hub.

- Visually inspect the hub for external damage, oil, and loose fasteners.

- Remove hub covers to check grease condition and look for metal particles.

- Check for axial and radial play by gently rocking the wheel/carrier.

- Spin by hand and listen for noises; use a stethoscope for internal noise localization.

- Measure runout and bearing clearances per OEM specifications if possible.

If you find significant contamination, scoring, or abnormal clearances, plan for hub replacement rather than temporary repairs.

Choosing the Right Replacement: OEM vs Aftermarket Excavator Parts

When a hub must be replaced, you face two main choices: OEM (original equipment manufacturer) parts or reputable aftermarket parts. Key considerations:

- Compatibility: Confirm the part number and mating dimensions. Using the correct hub ensures proper fit and load path.

- Material and heat treatment: Hubs endure heavy mechanical stresses. Quality control on material and heat treatment matters for life expectancy.

- Seals and bearings: Pre-installed seals and matched bearings reduce installation risk.

- Warranty and support: Reliable suppliers offer warranty and technical support for fitment and installation.

A quality aftermarket hub built to OEM standards can be a cost-effective choice — if the supplier provides technical certification and traceability.

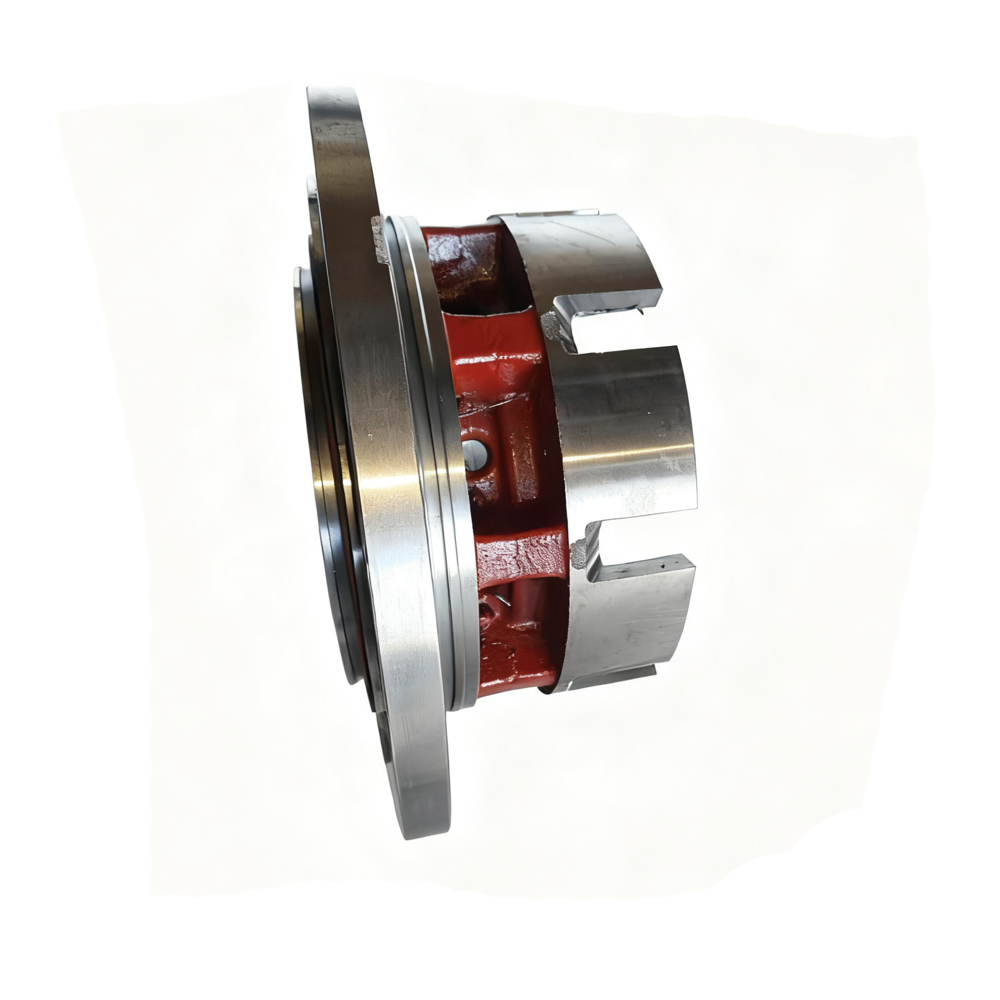

Product Highlight: Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 HUB SPARKLING MACHINERY

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

This hub is engineered as a direct replacement for Hyundai wheel/track carrier hubs for the listed models. For fleets running R160W9A or R170W-series machines, choosing a hub that meets OEM tolerances — like the ZGAQ-03591 — minimizes rework and supports predictable maintenance intervals.

Installation Tips and Best Practices for Excavator Parts Replacement

To get the most life from a new hub:

- Use proper lifting equipment and follow machine service manual torque specs for fasteners.

- Always use the specified lubricant and fill to recommended levels.

- Replace seals and bearings as a matched set when indicated.

- Check adjacent components (axle, sprockets, track links) and replace if worn; new hub on worn mating parts shortens service life.

- Perform a test run and re-torque fasteners after the initial operation hours as specified by the manufacturer.

Brand Advantages — Why SPARKLING MACHINERY Hubs Are a Strong Option

For operators considering replacement hubs, SPARKLING MACHINERY offers several advantages tied to the R160W9A/R170W-series hub (ZGAQ-03591):

- OEM-equivalent engineering: Manufactured to meet Hyundai OEM standards for fit and function, reducing fitment risk.

- Material and temperature resilience: Rated for -30°C to 100°C operation, suitable for wide climate ranges.

- Quality control and traceability: Controlled production processes reduce variability between batches.

- Cost-effectiveness: Typically lower cost than direct OEM while providing comparable performance when sourced from a certified supplier.

- After-sales support: Technical documentation and replacement guidance help field technicians install correctly and safely.

Selecting a supplier with documented quality processes and parts traceability protects fleets from premature failures and reduces total cost of ownership for excavator parts.

Frequently Asked Questions (FAQ)

Q: How long should a hub last under normal use?

A: Hub life varies with duty cycle, environment, and maintenance. In typical construction use with proper lubrication and no impacts, a hub can last many thousands of operating hours. Heavy mining duty, contamination, or impact damage will shorten life. Regular inspections are the best way to maximize hub life.

Q: Can I rebuild a damaged hub or must it be replaced?

A: Minor seal or bearing issues can sometimes be repaired, but structural damage, scored bores, or severe contamination usually require full hub replacement. Rebuilding must restore OEM tolerances to be reliable.

Q: Is the SPARKLING MACHINERY ZGAQ-03591 hub compatible with my Hyundai R170W7 excavator?

A: Yes — the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is specifically designed to meet Hyundai OEM specification ZGAQ-03591 and fits the listed models. Always verify your machine serial number and part number with the supplier prior to purchase.

Q: What routine checks prevent unexpected hub failures?

A: Check lubrication condition and levels, inspect for leaks, listen for unusual noises, measure play/runout during scheduled maintenance, and clean hubs after muddy or wet operations. Replacing seals promptly upon detection of leaks prevents contamination-related failures.

Q: Do aftermarket hubs void the machine warranty?

A: Using aftermarket parts may affect warranty terms depending on the OEM policy. If an aftermarket hub meets OEM specifications and is installed per OEM procedures, many manufacturers allow it, but you should confirm warranty terms with your dealer or the equipment manufacturer.

Contact Us / View the Product

If you suspect hub issues or need a certified replacement, contact our technical sales team for model verification, availability, and installation support. View details for the Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 HUB SPARKLING MACHINERY or request a quote by contacting our parts desk today.

References

- Cat - Undercarriage maintenance and best practices: https://www.cat.com/en_US/support/operations/maintenance/undercarriage.

- Hyundai Construction Equipment – Parts & Service overview: https://www.hyundai-ce.com/

- Noria Corporation - Common causes of bearing failure: https://www.noria.com/articles/common-causes-of-bearing-failure/

- General industry maintenance safety guidance (OSHA): https://www.osha.gov/

Wholesale heavy machinery control column manufacturer and supplier

Buyer's Guide to K9003219 Pulley Idler for Doosan DL450

Comparing OEM and Aftermarket Hydraulic Parts for Excavators

Best AC compressor for excavator manufacturers and supplier brands

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879