Signs of Genuine Hyundai Parts: A Practical Guide

- Signs of Genuine Hyundai Parts: A Practical Guide

- Why verifying authentic excavator parts matters

- Visual identification: markings, part numbers and cast features for excavator parts

- Packaging, labels and documentation for authentic excavator parts

- Technical compatibility: fit, tolerances and material checks for excavator parts

- Performance and lab tests: what to request or inspect

- Comparing genuine vs counterfeit: a quick reference table for excavator parts

- How to verify OEM part numbers and documentation for excavator parts

- Authorized channels and dealer verification for Hyundai excavator parts

- Case study: Inspecting the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub

- Warranty, returns and after-sales support — why they matter for excavator parts

- Brand advantages: why choosing genuine Hyundai parts for excavator parts pays off

- Practical buying checklist before committing to excavator parts

- FAQ — Frequently Asked Questions about Hyundai excavator parts and the ZGAQ-03591 hub

- Q1: How can I confirm the hub I received is the OEM ZGAQ-03591?

- Q2: Will using a non-genuine hub void my machine warranty?

- Q3: What tests can I realistically perform on-site before installation?

- Q4: Can a parts supplier provide proof that a hub was made to Hyundai OEM standards?

- Q5: What immediate signs suggest I should refuse a delivered hub?

- Contact / View product — take the next step

- References and sources

Signs of Genuine Hyundai Parts: A Practical Guide

Why verifying authentic excavator parts matters

For fleet managers, rental companies, and contractors, using authentic excavator parts is not just about brand loyalty — it impacts safety, machine uptime, warranty validity, and total cost of ownership. Counterfeit or incorrect undercarriage components (like hubs, final drives, sprockets and rollers) can fail prematurely, cause secondary damage, and increase downtime costs. This guide focuses on practical, field-tested signs to identify genuine Hyundai excavator parts — especially for undercarriage components — with an applied example: the Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub produced by SPARKLING MACHINERY.

Visual identification: markings, part numbers and cast features for excavator parts

One of the fastest checks is visual inspection. Genuine Hyundai parts typically carry clear, permanent markings: OEM part numbers (for example, ZGAQ-03591 for the hub), casting numbers, manufacturer codes, and sometimes holographic labels or QR codes. Key visual checks for excavator parts:

- Legible OEM part number stamped or cast in the metal — look for ZGAQ-03591 on the hub body or flange.

- Uniform machining and finishing: genuine hubs have consistent machining marks, smooth flange faces, and evenly spaced bolt holes within tolerances.

- Branding and logo placement: Hyundai genuine parts or approved manufacturers usually place logos or marks in consistent locations. Inconsistent fonts, misspellings, or fuzzy logos are red flags.

- Material surface quality: look for even heat-treat discoloration, absence of porosity or excessive sand casting roughness on critical sealing surfaces.

These visual checks are quick and can filter out obvious counterfeits before deeper verification.

Packaging, labels and documentation for authentic excavator parts

Packaging often reveals authenticity. Genuine Hyundai components come with specific packaging and documentation that counterfeiters rarely replicate fully. When inspecting packaging for excavator parts, check:

- Sealed box with Hyundai or OEM-branded tape and a part label including part number, barcode, and quantity.

- Accompanying documentation: a packing list, certificate of conformity, and sometimes warranty card or installation instructions listing the part number (ZGAQ-03591 for the hub example).

- QR codes or tamper-evident seals: many genuine parts include traceability codes you can scan for batch or origin confirmation.

If packaging looks generic, is missing labels, or lacks traceability, treat the part with caution.

Technical compatibility: fit, tolerances and material checks for excavator parts

Compatibility is more than matching a number. Genuine Hyundai parts are engineered to specific tolerances and materials to handle load, fatigue and environmental extremes. For a hub used on Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators, expect:

- Dimensional conformity: bolt circle diameter, bore dimension, flange thickness and mounting face runout must match OEM specifications.

- Material specification: typically high-strength alloy steel with required heat treatment to resist wear and impact.

- Temperature and environmental ratings: OEM hubs are specified to operate across a wide range (for example, -30°C to 100°C) without performance loss.

Field test: trial-fit the hub without forcing components; if bearings, seals or mating parts require excessive force or show unusual gaps, the part may not be genuine or correctly machined.

Performance and lab tests: what to request or inspect

When in doubt, request or perform simple performance/reliability checks. For excavator parts such as the ZGAQ-03591 hub:

- Hardness testing on non-critical surfaces can confirm heat treatment consistency.

- Magnaflux (MT) or dye-penetrant inspection for surface cracks in critical load areas.

- Material certificate (e.g., mill test report) that lists chemical composition and mechanical properties.

Vendors offering test reports and traceability demonstrate higher confidence than those who can only supply the part itself.

Comparing genuine vs counterfeit: a quick reference table for excavator parts

| Feature | Genuine Hyundai Parts | Counterfeit/Non-OEM |

|---|---|---|

| Part Number & Marking | Clear OEM number (e.g., ZGAQ-03591), consistent branding | Missing/wrong numbers, poor markings |

| Packaging & Documentation | Branded packaging, certificate, traceability | Generic packaging, no documentation |

| Material & Heat Treatment | Specified alloy with MTR/HTR records | Unknown material, inconsistent hardness |

| Fit & Tolerance | Precision-fit, correct clearances | Poor fit, requires modification |

| Warranty & Support | OEM warranty and dealer support | No warranty or limited seller claims |

Sources for table criteria include OEM best practices and industry maintenance guidelines (see references below).

How to verify OEM part numbers and documentation for excavator parts

OEM part numbers are authoritative. Steps to verify:

- Cross-check the part number against Hyundai parts catalogs or online OEM parts lookup. Many Hyundai dealers and the Hyundai Construction Equipment parts portal list serial/part compatibility (for models R160W9A, R170W7, R170W7A, R170W9).

- Ask the supplier for a certificate of conformity or mill test report that references batch numbers tied to the label on the package.

- Scan any QR codes or serial codes and verify the returned information matches the product and OEM part number.

If the seller resists providing these items, treat the purchase as high risk.

Authorized channels and dealer verification for Hyundai excavator parts

Buying from authorized dealers, distributor networks, or directly from Hyundai OEM channels is the most reliable way to ensure authenticity. Tips:

- Use the official Hyundai Construction Equipment dealer locator or contact Hyundai customer service for dealer confirmation.

- Check the seller's business registration, history in heavy equipment parts, and references from other customers.

- When buying online, prefer sellers with documented warranty policies, return procedures, and physical addresses.

Authorized channels also support warranty claims and technical assistance — invaluable after installation.

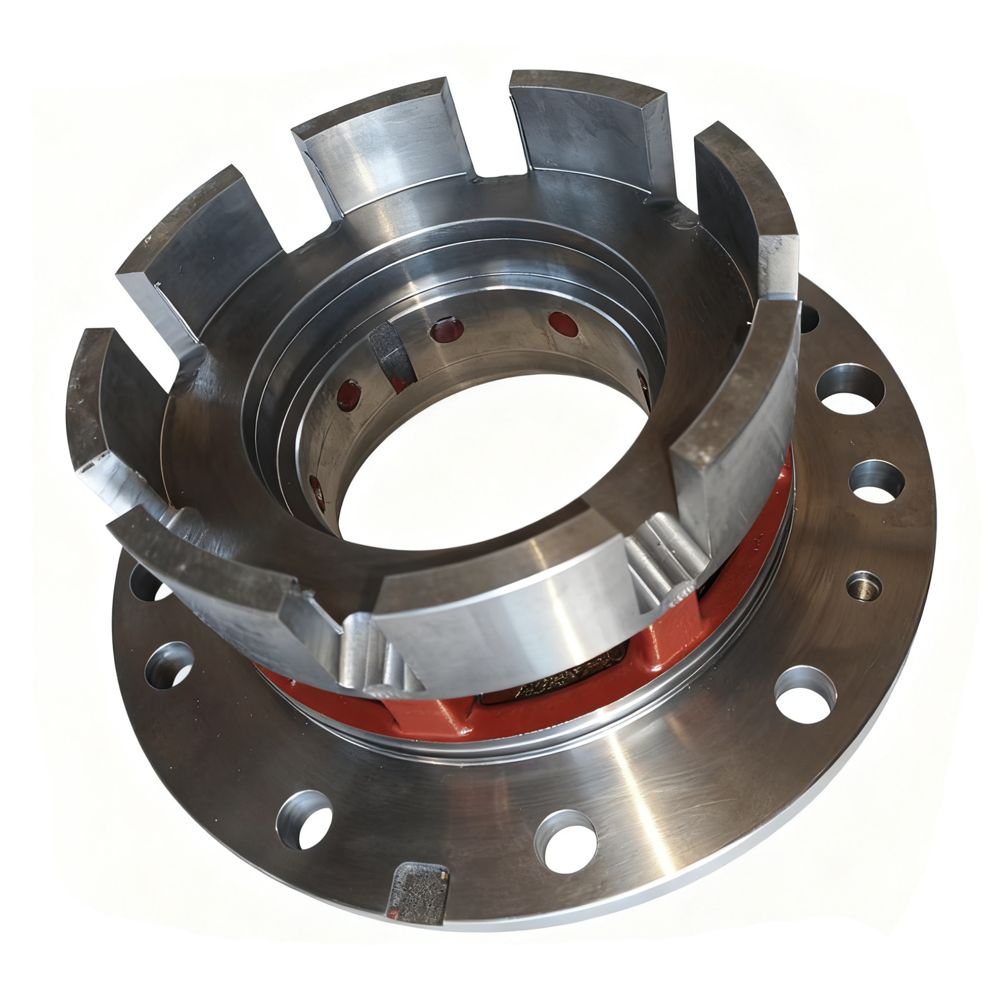

Case study: Inspecting the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub

Below is a practical inspection checklist tailored to the SPARKLING MACHINERY hub used on Hyundai wheeled excavators (R160W9A/R170W7/R170W7A/R170W9):

- Confirm packaging label lists: product name exactly as SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub and that the part number ZGAQ-03591 is visible and legible.

- Visually inspect the hub for casting or machining marks that match OEM references: check flange surface, bolt hole alignment, and hub bore concentricity.

- Request the mill test report (MTR) or material certificate from the supplier showing chemical composition and heat treatment results.

- Check operating temperature and wear resistance claims — the product description states resistance from -30°C to 100°C; verify that via material datasheet or MTR.

- Fit test on a non-critical machine or during scheduled downtime: verify mating with existing axle and track assemblies without excessive force.

Completing these steps will significantly reduce the risk of installing a non-conforming hub that could compromise travel stability or load performance.

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

Warranty, returns and after-sales support — why they matter for excavator parts

Genuine parts normally come with a clear warranty and return policy. Before purchase, confirm:

- Length and coverage of warranty (labor vs. part-only coverage).

- Return window and condition requirements for cores or used parts.

- Availability of technical support for installation or troubleshooting.

A seller who stands behind their parts with clear warranty terms and post-sale support is more likely selling quality, authentic components.

Brand advantages: why choosing genuine Hyundai parts for excavator parts pays off

Choosing genuine Hyundai-certified parts (or OEM-equivalent parts meeting OEM standards) delivers measurable advantages:

- Reliability: engineered fit and materials reduce failure modes and secondary damage.

- Uptime: correct parts reduce unscheduled downtime and maintenance frequency.

- Resale value: machines maintained with OEM parts retain higher resale value.

- Warranty compliance: using authentic parts preserves engine and machine warranties.

For SPARKLING MACHINERY-produced hubs that meet ZGAQ-03591 OEM standards, buyers gain the practical benefits of compatibility and expected lifecycle performance when verification steps are followed.

Practical buying checklist before committing to excavator parts

Use this short checklist before purchase:

- Verify OEM part number and cross-check with Hyundai parts catalog.

- Inspect packaging, labels and request supporting documents (MTR, certificate of conformity).

- Confirm seller is an authorized dealer or has verifiable references.

- Request warranty and return policy in writing.

- Perform a trial fit or accept a tested return policy if the part doesn’t meet expectations.

FAQ — Frequently Asked Questions about Hyundai excavator parts and the ZGAQ-03591 hub

Q1: How can I confirm the hub I received is the OEM ZGAQ-03591?

A1: Cross-check the part number on the hub and packaging against Hyundai parts catalog entries for R160W9A/R170W7/R170W7A/R170W9. Request the supplier’s traceability documents (MTR, COA) and scan any QR code or serial code included on the label.

Q2: Will using a non-genuine hub void my machine warranty?

A2: It depends on the warranty terms. Many OEM warranties require genuine parts for continued coverage. Installing non-genuine parts can void repair or warranty claims if a failure is linked to the aftermarket component.

Q3: What tests can I realistically perform on-site before installation?

A3: Visual inspection, dimension checks (bolt circle, bore diameter), trial-fit, and checking labeling/packaging are practical on-site tests. For material verification, request MTRs or third-party hardness testing from the supplier or a nearby lab.

Q4: Can a parts supplier provide proof that a hub was made to Hyundai OEM standards?

A4: Yes — ask for certificates of conformity, MTRs, and any OEM approval documentation. Some approved manufacturers will provide explicit statements or vendor approval numbers tied to Hyundai’s procurement process.

Q5: What immediate signs suggest I should refuse a delivered hub?

A5: Obvious signs include missing or wrong part numbers, damaged or generic packaging, poor machining on critical surfaces, or refusal by the seller to provide traceability documents or warranty terms.

Contact / View product — take the next step

For owners of the Hyundai R160W9A, it's important to know what essential spare parts you should always have on hand. These parts are critical for minimizing downtime and ensuring the continued smooth operation of your equipment.If you want assistance verifying a ZGAQ-03591 hub, comparing offers, or purchasing OEM-compliant excavator parts, contact our parts team. We can provide verification support, documentation review, and advise on authorized channels. To view product details and request a quote for the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub, please contact our sales team or request a parts inspection.

Contact: sales@example.com | Phone: +1-800-000-0000 | Request product page: /products/zgaq-03591-hub

References and sources

- Hyundai Construction Equipment — Official parts catalogs and dealer resources: https://www.hyundai-ce.com (Hyundai construction equipment pages and parts lookup)

- ISO — Quality management systems: https://www.iso.org/iso-9001-quality-management.

- Industry guidance on undercarriage inspection and maintenance — ForConstructionPros: https://www.forconstructionpros.com (articles on undercarriage wear and parts verification)

- General OEM parts traceability and MTR best practices — ASTM and industrial supply resources (see supplier mill test report guidance pages)

The B2B Buyer’s Guide to Excavator Hydraulic Pumps

Best carrier roller excavator manufacturers and supplier brands

Inspection Routine Before Long Excavator Jobs

2026 Cost Breakdown of Hydraulic System Components

faq

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879