Quality Indicators for Sparkling Machinery Taper Roller Bearings

- How Bearings Interact with Excavator Systems

- Load types and operating environments

- Functional placement among parts of an excavator

- Why HYUNDAI OEM compatibility matters

- Design and Manufacturing Quality Indicators

- Materials, heat treatment and surface integrity

- Dimensional accuracy, tolerances and geometry

- Seals, cages and lubrication paths

- Performance Testing, Standards and Evidence

- Laboratory and field testing indicators

- Industry standards and authoritative references

- Comparative table: bearing types for excavator applications

- Maintenance, Installation and Practical Selection Tips

- Correct installation and preload

- Lubrication strategy and contamination control

- When to inspect or replace a bearing

- Product focus: HYUNDAI EXCAVATOR PARTS HW210 R200W7 R200W7A R210W-9 ZGAQ-02328

- Buying and Verification Checklist

- Supplier documentation and traceability

- On-receipt inspection steps

- Cost vs lifespan: total cost of ownership

- FAQ — Quality, Use and Maintenance

- Q: How do I confirm ZGAQ-02328 is the correct replacement?

- Q: What are the most common failure modes for tapered roller bearings in excavators?

- Q: How often should bearings be inspected or regreased?

- Q: Can I rely on aftermarket bearings from third-party suppliers?

- Q: Which standard documents or references should I consult for bearing life and selection?

Taper roller bearings are critical rotating components among the parts of an excavator, carrying combined radial and axial loads on shafts that drive swing systems, travel motors, booms, and buckets. This article details measurable quality indicators—material, heat treatment, dimensional accuracy, surface finish, lubrication, and testing—that determine long-term performance of the SPARKLING MACHINERY ZGAQ-02328 (HYUNDAI OEM ZGAQ-02328) used on HW210 / R200W7 / R200W7A / R210W-9 machines. It helps fleet managers, maintenance engineers and procurement professionals choose, verify and maintain bearings for optimal uptime.

How Bearings Interact with Excavator Systems

Load types and operating environments

Excavator parts such as the boom, arm, bucket linkage, swing bearing and travel gearbox create complex load patterns: heavy radial loads from bucket digging and lifting, plus axial thrust during slewing and side loads when working on slopes. Environmental factors—dust, water, heavy impact, and temperature swings—also stress bearings. A tapered roller bearing for these applications must be rated for high dynamic and static loads and designed to tolerate contamination and shock.

Functional placement among parts of an excavator

Tapered roller bearings are commonly used in swing units, final drives, wheel hubs (on wheeled excavators), and certain pivot shafts. They sit alongside other key components such as hydraulic pumps, swing motors, pins and bushings, track rollers and sprockets. Understanding where the bearing sits in the kinematic chain helps prioritize inspection intervals and lubrication strategies for the surrounding components.

Why HYUNDAI OEM compatibility matters

OEM compatibility (Part No.: ZGAQ-02328 for HYUNDAI) ensures correct fit into housings and correct preload/tolerance relationships with mating parts like shafts and housings. Using a matching part minimizes machining or fit issues that could accelerate wear on adjacent parts of an excavator—such as the swing gear, gearbox shafts or undercarriage linkages.

Design and Manufacturing Quality Indicators

Materials, heat treatment and surface integrity

The core indicators of bearing longevity are steel grade, heat treatment, and surface finish. Bearings for heavy equipment typically use high-carbon chromium bearing steels (e.g., SAE 52100 or equivalent) with controlled case hardness and fatigue resistance. Proper induction hardening or through-hardening processes reduce subsurface defects that lead to spalling under rolling contact fatigue. Surface finishes and shot-peening (where applicable) improve fatigue life and resist crack initiation.

Dimensional accuracy, tolerances and geometry

Precision in raceway geometry, roller profile, and concentricity directly affects load distribution. Quality bearings adhere to tight dimensional tolerances and measured internal clearances. Key measurable indicators include bore / OD tolerances, runout, radial and axial clearance, and cone/cup coaxiality. These affect how the bearing handles combined radial and axial forces generated by components such as the slewing ring and boom pivot.

Seals, cages and lubrication paths

Seals prevent ingress of abrasive dust and water—common in excavation sites—while cages maintain roller spacing under dynamic conditions. High-quality polymer or steel cages and robust contact/non-contact lip seals are crucial. Design features that facilitate relubrication (grease ports, labyrinth seals) improve service life when integrated with the machine's centralized lubrication on bucket pins, boom joints and swing bearings.

Performance Testing, Standards and Evidence

Laboratory and field testing indicators

Manufacturers should provide fatigue life (L10/L50) ratings, dynamic and static load ratings, and recorded test cycles under simulated operating conditions. Common lab tests include rolling fatigue, impact resistance, and corrosion resistance. Field tests confirm behavior under real loads and contamination. Compare manufacturer data and independent test reports when deciding between replacement bearings.

Industry standards and authoritative references

Referencing established standards strengthens purchasing decisions: SKF provides detailed technical resources on tapered roller bearings and testing methods (SKF tapered roller bearings), while general bearing technology and life calculation principles are summarized on Wikipedia. Trade organizations like the American Bearing Manufacturers Association provide industry guidelines and standards (ABMA).

Comparative table: bearing types for excavator applications

| Characteristic | Tapered Roller Bearing | Cylindrical Roller Bearing | Ball Bearing |

|---|---|---|---|

| Handles combined radial & axial loads | Excellent | Good (mainly radial) | Limited (low axial capacity) |

| Shock & impact resistance | High | Moderate | Lower |

| Typical use in excavators | Swing units, hubs, final drives | Gearbox shafts | Accessory shafts, sensors |

| Service/maintenance complexity | Requires careful preload & lubrication | Easier mounting but alignment sensitive | Simple mounting but lower load rating |

Maintenance, Installation and Practical Selection Tips

Correct installation and preload

Installation is a prime determinant of bearing life. Incorrect preload—either under- or over-tightening—causes uneven roller loading, accelerated wear, and heat generation affecting nearby components like swing gear and hydraulic drive shafts. Use calibrated torque tools, verify axial play, and follow OEM installation specifications for HYUNDAI parts to ensure compatibility with housings and seals.

Lubrication strategy and contamination control

Grease selection should match operating temperature, load and speed. For heavy excavation duty, lithium-complex or polyurea greases with extreme pressure (EP) additives and solid contamination barriers are common. Centralized lubrication for pins and bushings, and scheduled greasing for swing bearings and travel motors, significantly extend bearing life. Replace seals at scheduled intervals to prevent ingress that would accelerate wear on bearings and adjacent parts like track rollers and sprockets.

When to inspect or replace a bearing

Planned inspections should include vibration signature analysis, noise checks, endplay measurement and visual inspection for flaking or discoloration. Common failure signs: increased vibration during slewing, elevated operating temperature, and visible scoring on rollers or raceways. If the bearing showing these signs is in critical locations (swing bearing or final drive), plan replacement promptly to avoid collateral damage to gearbox shafts or the undercarriage.

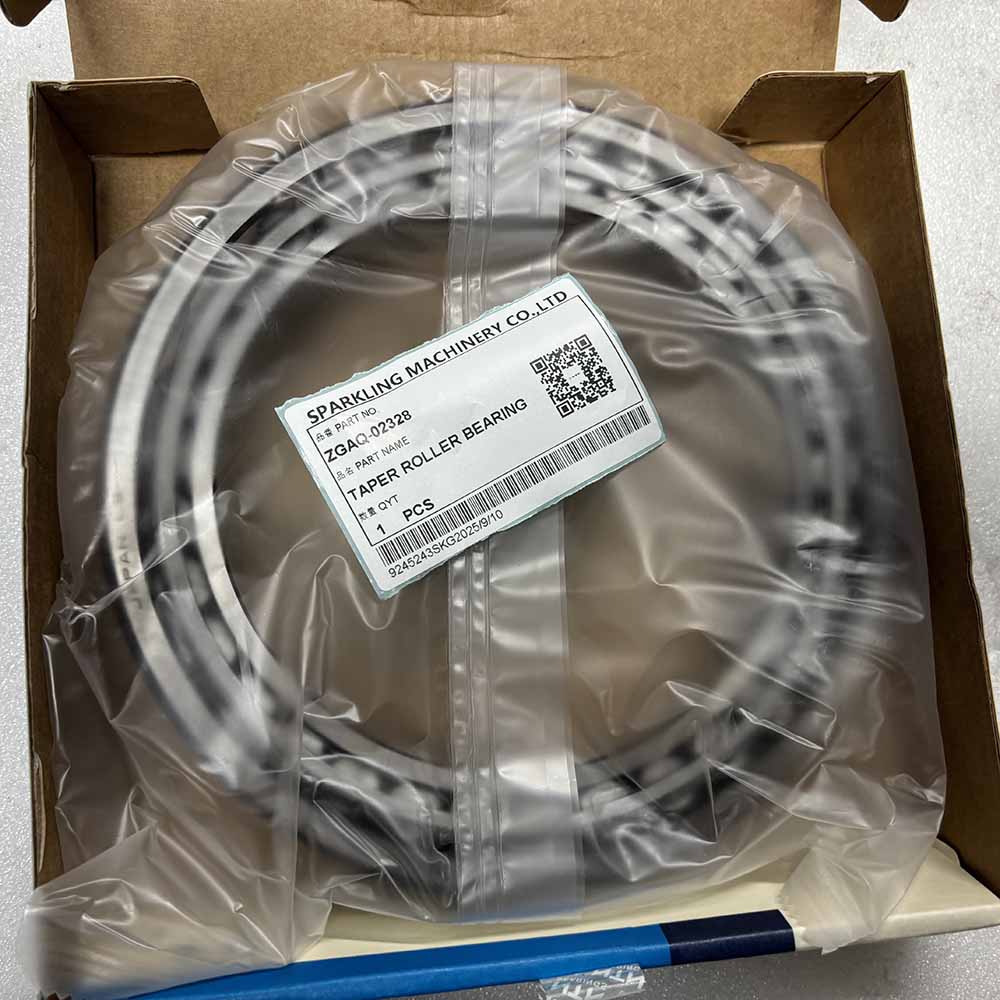

Product focus: HYUNDAI EXCAVATOR PARTS HW210 R200W7 R200W7A R210W-9 ZGAQ-02328

SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing is a core rotating component for Hyundai excavators (construction/mining use). It withstands combined radial and axial loads, ensuring smooth rotation of key shaft parts.

Meeting Hyundai OEM standards (Part No.: ZGAQ-02328), it delivers high wear resistance and load capacity, guaranteeing seamless compatibility and long-term stable operational performance.

This specific part is designed to integrate into the machine’s assembly with the correct tolerances and preload settings required by HYUNDAI. When replacing bearings in a machine for components such as the swing unit or the travel hub, verify seals, mating shafts (main shaft or drive pin), and housing bores to prevent misfit issues that could affect other parts of an excavator (pins & bushings, hydraulic cylinders, swing motor).

Buying and Verification Checklist

Supplier documentation and traceability

Require material certificates, heat treatment records, and batch traceability from the supplier. Certificates that reference manufacturing standards and test results reduce risk. For critical parts, request sample inspection reports and bearings’ L10 life estimates under specified loads.

On-receipt inspection steps

On arrival, check packaging integrity, dimension checks (bore, OD, width), runout measurement, and visual inspections for machining marks or corrosion. If available, compare to OEM part drawing tolerances. Keep records of these checks, as they support warranty claims and replacement planning for other parts of an excavator that may be affected.

Cost vs lifespan: total cost of ownership

Don’t base decisions solely on unit cost. Consider labor for replacement (excavator downtime), potential damage to adjacent components (swing gear, gearbox, hydraulic piping), and failure modes. Higher-quality bearings with verified test reports and OEM compatibility usually lower total lifecycle costs through improved uptime.

FAQ — Quality, Use and Maintenance

Q: How do I confirm ZGAQ-02328 is the correct replacement?

A: Cross-check the HYUNDAI OEM part number, machine model (HW210, R200W7, R200W7A, R210W-9), and the bearing physical dimensions (bore, OD, width). Confirm tolerance class and preload specs from manufacturer documentation or your machine’s service manual.

Q: What are the most common failure modes for tapered roller bearings in excavators?

A: Typical failures are rolling contact fatigue (spalling), contamination-induced wear, inadequate lubrication leading to overheating, and incorrect preload or misalignment. Regular inspection and correct installation minimize these risks.

Q: How often should bearings be inspected or regreased?

A: Frequency depends on operating conditions. For heavy-duty mining or continuous excavation work, perform lubrication checks weekly and full inspections every 250–500 operating hours. For lighter construction use, service intervals may be longer. Always follow HYUNDAI maintenance intervals in the operator’s manual.

Q: Can I rely on aftermarket bearings from third-party suppliers?

A: High-quality aftermarket bearings can be acceptable if they provide complete certification, tested L10 life data, and dimensional conformity to OEM specifications. Prioritize suppliers with traceability and positive field performance records.

Q: Which standard documents or references should I consult for bearing life and selection?

A: Refer to manufacturers’ technical guides (e.g., SKF), industry associations such as ABMA, and technical summaries like Wikipedia’s tapered roller bearing page for calculation methods and life estimation principles.

Contact & Product CTA: For OEM-compatible replacements, technical drawings, availability and pricing of SPARKLING MACHINERY NEW ZGAQ-02328 (HYUNDAI EXCAVATOR PARTS HW210 R200W7 R200W7A R210W-9), contact our parts team or view the product page. Our specialists can provide cross-references, installation guidance and service interval recommendations to protect your excavator’s swing bearing, undercarriage and hydraulic systems. Contact us or view product details today.

Maintenance Checklist for Hyundai R160W9A Excavators

Inspection Checklist for K9003219 Pulley Idler on Arrival

2026 Guide to Hydraulic Pumps and Motors for Excavators

The Impact of Quality Hydraulic Parts on Excavator Performance

faq

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

K5V212DPH1J8R-9NG4-AV Hydraulic Pump - Construction Machinery Spare Parts fits EC300D EC350D EC380D R335LC-9V

The K5V212DPH1J8R-9NG4-AV is an OEM-compatible variable displacement axial piston main hydraulic pump, custom-engineered for Volvo EC300D/EC350D/EC380D and Hyundai R335LC-9V 30-38 ton excavators.

Key Features

· High-power output: 212cc displacement, max pressure 34.3 MPa, 1800 rpm rated speed—matches 150-190kW engine power for 30-38 ton excavators, ensuring efficient high-load operation.

· Precision flow control: Electro-hydraulic proportional control adjusts output per workload, cutting fuel consumption by 8% vs. standard pumps while maintaining smooth actuator response.

· Direct OEM fit: Exact mounting points, hydraulic ports, and SAE J518 flanges enable plug-and-play installation without system reconfiguration or adapter parts.

· Durable components: Hardened cylinder block, chrome-plated pistons, and wear-resistant valve plate extend service life; integrated pressure relief valve prevents overload damage.

Compatible Models & Part Numbers

· Volvo Excavators: EC300D, EC350D, EC380D

· Hyundai Excavators: R335LC-9V

· Part Number: K5V212DPH1J8R-9NG4-AV

· Interchangeable References: K5V212DPH-9N series; matches original main pump specs for above models

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879