The B2B Buyer’s Guide to Undercarriage Parts for Excavators

- The B2B Buyer’s Guide to Undercarriage Parts for Excavators

- Introduction: Why Undercarriage Parts for Excavators Matter

- Understanding Key Components of Undercarriage Systems

- Materials and Manufacturing: What to Look For

- OEM vs Aftermarket: Balancing Cost and Risk

- Compatibility and Fitment: Avoiding Costly Mistakes

- Performance Testing and Quality Control

- Warranty and After-Sales Support

- Lead Times, Stocking Strategies, and Supply Chain Resilience

- Inspection and Acceptance Criteria at Delivery

- Total Cost of Ownership (TCO): Looking Beyond Unit Price

- Maintenance Best Practices to Maximize Part Life

- Choosing a Strategic Supplier: What Sets Top Suppliers Apart

- SPARKLING MACHINERY: A Trusted Partner for Excavator Undercarriage Parts

- Case Study: Reducing Fleet Downtime with Quality Undercarriage Parts

- Procurement Checklist for Undercarriage Parts for Excavators

- Customization and Special Orders: When to Specify Custom Parts

- Certifications and Compliance: Ensuring Safe and Legal Purchases

- Negotiating Contracts and Volume Discounts

- Logistics, Packaging, and Handling of Heavy Components

- Digital Tools: Inventory Management and Predictive Maintenance

- Sustainability and Recycling Options

- Conclusion: Building a Robust Undercarriage Parts Strategy

- Next Steps: How to Begin Sourcing Better Undercarriage Parts

- Frequently Asked Questions

The B2B Buyer’s Guide to Undercarriage Parts for Excavators

Introduction: Why Undercarriage Parts for Excavators Matter

Undercarriage parts for excavators directly influence machine uptime, safety, and operating cost. As a procurement manager or fleet owner, investing in the right undercarriage components—track chains, sprockets, rollers, idlers, and shoes—delivers predictable performance and reduces total cost of ownership (TCO). This guide helps B2B buyers make informed decisions about quality, compatibility, warranty, and supplier selection.

Understanding Key Components of Undercarriage Systems

Undercarriage parts for excavators include track chains, track shoes, sprockets, carrier rollers, track rollers, and idlers. Each component has a specific wear pattern and replacement cycle; buying compatible, high-quality parts prevents premature failures. Knowing each component's role makes procurement conversations with suppliers more strategic.

Materials and Manufacturing: What to Look For

High-performance undercarriage parts for excavators are typically made from heat-treated alloy steel with surface treatments such as carburizing or induction hardening to resist wear and impact. Ask suppliers for material certificates, hardness test results, and heat treatment processes to verify part durability and consistency.

OEM vs Aftermarket: Balancing Cost and Risk

When evaluating undercarriage parts for excavators, weigh OEM equivalence against aftermarket price advantages. OEM parts often guarantee fitment and compatibility, while quality aftermarket suppliers can offer cost savings and customization. For B2B buyers, consider lifecycle costs, not just purchase price—higher upfront quality often reduces downtime and change-out frequency.

Compatibility and Fitment: Avoiding Costly Mistakes

Exact-fit undercarriage parts for excavators prevent installation issues and accelerated wear. Confirm part numbers, serial ranges, and dimensional drawings with suppliers. For mixed fleets, standardize parts where possible to simplify inventory and speed repairs.

Performance Testing and Quality Control

Request supplier quality documentation for undercarriage parts for excavators, including ISO 9001 certification, dimensional inspection reports, metallurgical tests, and hardness mapping. Reliable suppliers use controlled production processes and non-destructive testing to ensure each batch meets specifications.

Warranty and After-Sales Support

Strong warranties and technical support are important when buying undercarriage parts for excavators. Ask about warranty terms, return policies, and whether the supplier provides installation guidance, field troubleshooting, and expedited replacement logistics to minimize downtime.

Lead Times, Stocking Strategies, and Supply Chain Resilience

For B2B buyers, managing lead times for undercarriage parts for excavators is essential. Maintain critical-stock policies for high-wear items and negotiate safety-stock agreements with suppliers. Diversify your supplier base and confirm backup manufacturing capacity to avoid production halts caused by supply disruptions.

Inspection and Acceptance Criteria at Delivery

Set clear inspection and acceptance criteria for undercarriage parts for excavators. On receipt, verify part numbers, dimensions, surface treatment, and hardness where applicable. Reconcile shipment documentation and report any discrepancies immediately to safeguard warranty coverage.

Total Cost of Ownership (TCO): Looking Beyond Unit Price

Calculate TCO for undercarriage parts for excavators by including purchase price, installation labor, downtime costs, expected service life, and disposal. Parts that provide longer wear life, easier serviceability, or lower maintenance needs often reduce TCO even with a higher initial price.

Maintenance Best Practices to Maximize Part Life

Implement preventive maintenance: keep proper track tension, remove debris, monitor wear on rollers and sprockets, rotate track shoes when appropriate, and maintain hydraulic systems to avoid abnormal undercarriage stress. These practices extend the life of undercarriage parts for excavators and protect your investment.

Choosing a Strategic Supplier: What Sets Top Suppliers Apart

Top suppliers of undercarriage parts for excavators combine product quality, customizable solutions, technical support, and global logistics. Look for manufacturers with strict quality control, R&D for continuous improvement, and the ability to support multiple major OEM models—traits that make suppliers reliable long-term partners.

SPARKLING MACHINERY: A Trusted Partner for Excavator Undercarriage Parts

SPARKLING MACHINERY, founded in 2013, focuses on high-quality excavator parts and undercarriage systems compatible with Caterpillar, Komatsu, Hitachi, Volvo and other major brands. The company emphasizes stability, precision, and endurance through strict manufacturing and quality control. For B2B buyers, SPARKLING MACHINERY offers customized solutions, technical support, and competitive pricing that help fleets reduce costs while maintaining reliability.

Case Study: Reducing Fleet Downtime with Quality Undercarriage Parts

A mid-sized contractor replaced lower-quality aftermarket undercarriage parts with higher-grade components and improved inspection intervals. The result was fewer unscheduled repairs and a measurable reduction in hourly downtime costs. This illustrates how investing in better undercarriage parts for excavators yields operational benefits and cost savings over time.

Procurement Checklist for Undercarriage Parts for Excavators

Create a standard procurement checklist that covers compatibility, material certificates, warranty, lead time, MOQ (minimum order quantity), and after-sales service. Use a scorecard to compare suppliers objectively and prioritize long-term value over the lowest bid.

Customization and Special Orders: When to Specify Custom Parts

Custom undercarriage parts for excavators are appropriate when machines operate in extreme environments or when fleet standardization demands specific adaptations. Work with manufacturers who can provide engineering drawings, prototype validation, and production run testing to ensure performance before full-scale procurement.

Certifications and Compliance: Ensuring Safe and Legal Purchases

Confirm suppliers meet industry certifications such as ISO 9001 for quality management and relevant regional regulations for materials and shipping. Compliance reduces project risk and helps with warranty claims and cross-border logistics for international operations.

Negotiating Contracts and Volume Discounts

Negotiate contracts that include volume discounts, scheduled deliveries, and performance-based penalties or incentives. Long-term agreements with reliable suppliers can secure better pricing on undercarriage parts for excavators and prioritized production slots during peak demand.

Logistics, Packaging, and Handling of Heavy Components

Discuss transport packaging and special handling requirements for heavy undercarriage parts for excavators. Proper packaging prevents damage in transit; suppliers with proven logistics processes reduce the risk of receiving compromised parts that would delay repairs.

Digital Tools: Inventory Management and Predictive Maintenance

Integrate inventory management systems and condition-monitoring tools to predict undercarriage part replacements. Digital tracking of operating hours and wear patterns helps schedule replacements proactively, minimizing emergency parts orders and downtime.

Sustainability and Recycling Options

Consider suppliers that use environmentally responsible manufacturing and recycling programs. Recycling worn undercarriage components and selecting suppliers committed to reducing waste supports corporate sustainability goals and may offer cost benefits for disposal.

Conclusion: Building a Robust Undercarriage Parts Strategy

Effective B2B procurement of undercarriage parts for excavators requires balancing part quality, supplier reliability, and lifecycle costs. Prioritize verified materials, solid warranties, and suppliers who offer technical support and consistent delivery. Strategic partnerships with manufacturers like SPARKLING MACHINERY can help fleets improve uptime, control costs, and scale operations globally.

Next Steps: How to Begin Sourcing Better Undercarriage Parts

Start by auditing your fleet, identifying high-wear components, and building a prioritized parts list. Contact trusted suppliers for samples, material certificates, and lead-time estimates. Implement a procurement scorecard and pilot any new parts on a limited number of machines before full rollout.

Contact: For tailored solutions on undercarriage parts for excavators, technical support, or custom orders, reach out to SPARKLING MACHINERY to discuss specifications, compatibility, and pricing.

Note: The recommendations above are based on industry best practices. Specific service life and replacement cycles vary by machine model, operating environment, and maintenance practices.

Frequently Asked Questions

Q: What are the most commonly replaced undercarriage parts for excavators?A: Track chains, track shoes, sprockets, track rollers, carrier rollers, and idlers are typically replaced most often due to wear and impact. Replacement frequency depends on operating conditions and maintenance practices.

Q: How can I verify the quality of undercarriage parts for excavators before buying?A: Request material certificates, hardness and metallurgical test reports, dimensional drawings, and ISO 9001 or equivalent quality certifications. Ask for samples or pilot batches and check supplier references.

Q: Is it better to buy OEM or aftermarket undercarriage parts?A: Both have pros and cons. OEM parts ensure fitment and brand consistency, while reputable aftermarket suppliers can offer cost savings and customization. Evaluate on TCO, warranty, and supplier reliability.

Q: How should I manage inventory for critical undercarriage components?A: Maintain safety stock for high-wear parts, standardize components across fleets where possible, and use inventory management software to track usage rates and trigger reorder points.

Q: What maintenance practices extend the life of undercarriage parts?A: Maintain proper track tension, remove rocks and debris regularly, monitor wear patterns, rotate shoes if applicable, and address hydraulic issues quickly to prevent abnormal stresses.

Q: Can undercarriage parts be refurbished or remanufactured?A: Some components, like rollers and idlers, may be refurbishable depending on damage and wear. Evaluate refurbishment based on remaining material thickness, safety, and cost-effectiveness versus new parts.

Q: How long does it take to receive custom undercarriage parts?A: Lead times vary by complexity, material availability, and supplier capacity. Discuss delivery schedules, prototyping timelines, and expedited options with your supplier when planning custom orders.

Q: What certifications should a reliable undercarriage parts supplier have?A: Look for ISO 9001 (quality management) and documented testing protocols. Regional and industry-specific certifications can also be relevant depending on your market and operational requirements.

Hyundai Excavator Parts: What Makes Quality Parts Stand Out

Best excavator electric switch manufacturers and supplier brands

Understanding Wear Patterns on Excavator Hubs

Best rubber track for excavator manufacturers and supplier brands

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

HIGH-QUALITY 22B-54-16221 HANDLE for KOMATSU Construction Equipment PC45MR PC55MR PC78US PC78UU PC88MR PC138 PC228US Excavator

The HIGH-QUALITY 22B-54-16221 HANDLE is a premium operational component meticulously engineered for KOMATSU Construction Equipment, specifically tailored to meet the precise control needs of PC45MR, PC55MR, PC78US, PC78UU, PC88MR, PC138, and PC228US excavators. As a critical part of the machinery’s operator control system, this handle delivers responsive, ergonomic operation, enabling precise manipulation of excavator functions while ensuring comfort during long working hours. It is designed to seamlessly integrate with KOMATSU’s excavator control architecture, guaranteeing consistent performance that enhances operational efficiency and operator experience.

Key Features

· Custom-engineered for perfect compatibility with KOMATSU PC45MR, PC55MR, PC78US, PC78UU, PC88MR, PC138, PC228US excavators

· Ergonomic design with optimized grip texture and contour for reduced operator fatigue during extended use

· High-strength, wear-resistant material construction for durability in harsh construction environments

· Precision-machined connection points for secure installation and responsive control feedback

· Strict adherence to KOMATSU OEM specifications for seamless integration and reliable performance

Compatible Models

· KOMATSU Construction Equipment Excavators: PC45MR, PC55MR, PC78US, PC78UU, PC88MR, PC138, PC228US

HIGH-QUALITY 21U-01-31211 CUSHION for KOMATSU Construction Equipment PC27MR PC30MR PC30MRX PC30UU PC35MR Excavator

The HIGH-QUALITY 21U-01-31211 CUSHION is a premium protective component meticulously engineered for KOMATSU Construction Equipment, specifically tailored to the operational needs of PC27MR, PC30MR, PC30MRX, PC30UU, and PC35MR excavators. As a critical part of the machinery’s shock absorption and protection system, this cushion effectively mitigates impact forces, reduces vibration, and shields key mechanical components from wear and damage during heavy-duty construction operations. It is designed to seamlessly integrate with KOMATSU’s excavator architecture, ensuring consistent performance that enhances the machinery’s service life and operational safety.

Key Features

· Custom-engineered for perfect compatibility with KOMATSU PC27MR, PC30MR, PC30MRX, PC30UU, PC35MR excavators

· High-density, wear-resistant material construction for superior impact absorption and long-term durability

· Precision-molded design to fit exact component contours, ensuring optimal shock mitigation and stability

· Resistance to oil, grease, and harsh environmental factors (dust, moisture, temperature variations)

· Strict adherence to KOMATSU OEM specifications for seamless integration and reliable performance

Compatible Models

· KOMATSU Construction Equipment Excavators: PC27MR, PC30MR, PC30MRX, PC30UU, PC35MR, PC35MRX, PC38UU

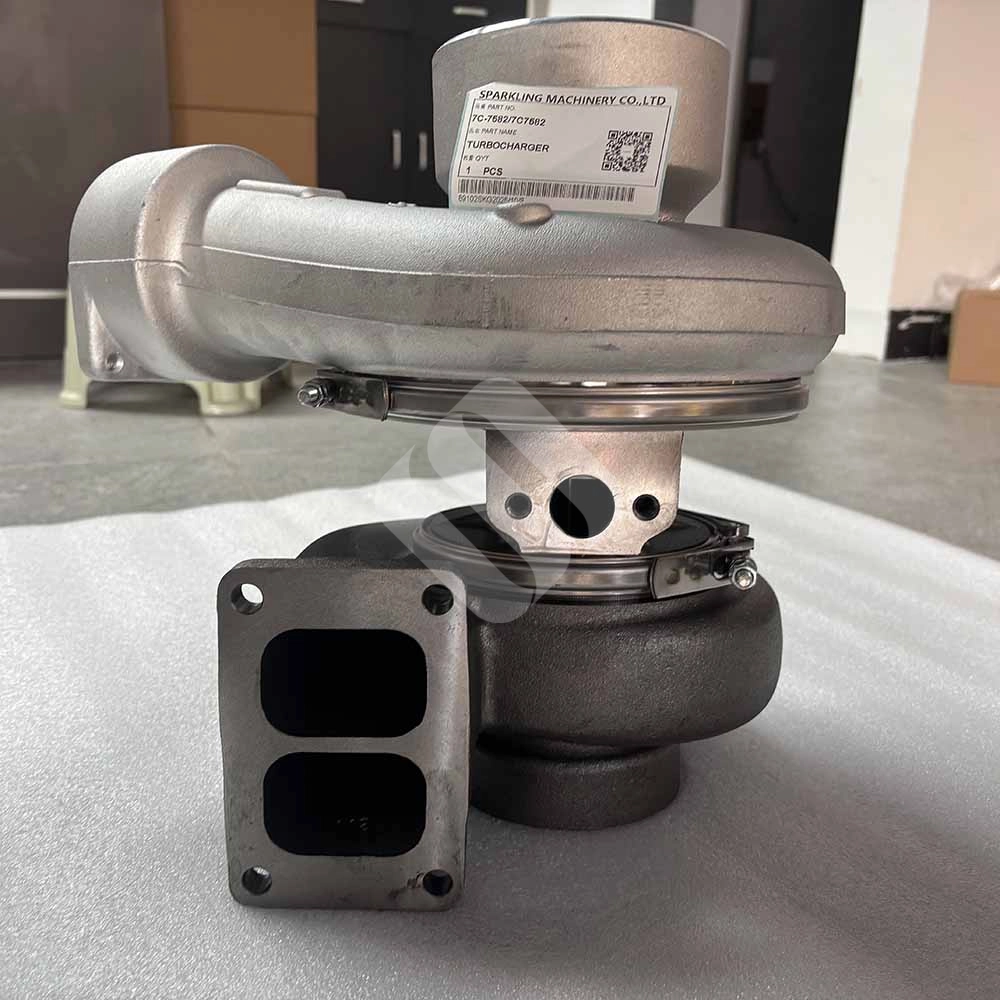

HIGH-QUALITY 7C-7582/7C7582 TURBOCHARGER for Caterpillar Construction Equipment 3306 3306B D25D D300D Excavator

The HIGH-QUALITY 7C-7582/7C7582 TURBOCHARGER is a premium power-enhancing component meticulously engineered for Caterpillar Construction Equipment, specifically tailored to meet the high-performance demands of 3306, 3306B, D25D, and D300D excavators. As a critical part of the engine system, this turbocharger optimizes air intake efficiency, boosts engine power output, and improves fuel combustion efficiency—all while ensuring stable operation even in the most demanding construction environments. It is designed to seamlessly integrate with Caterpillar’s engine architecture, delivering consistent performance that enhances the overall productivity of your machinery.

Key Features

· Custom-engineered for perfect compatibility with Caterpillar 3306, 3306B, D25D, D300D excavators

· Advanced turbine and compressor design for maximum air compression efficiency and power boost

· High-temperature resistance and wear-resistant components for long-term reliability in harsh working conditions

· Precision-balanced rotating assembly to minimize vibration and extend service life

· Strict adherence to Caterpillar OEM specifications for consistent performance and seamless integration

Compatible Models

Caterpillar Construction Equipment Excavators: 3306, 3306B, D25D, D300D

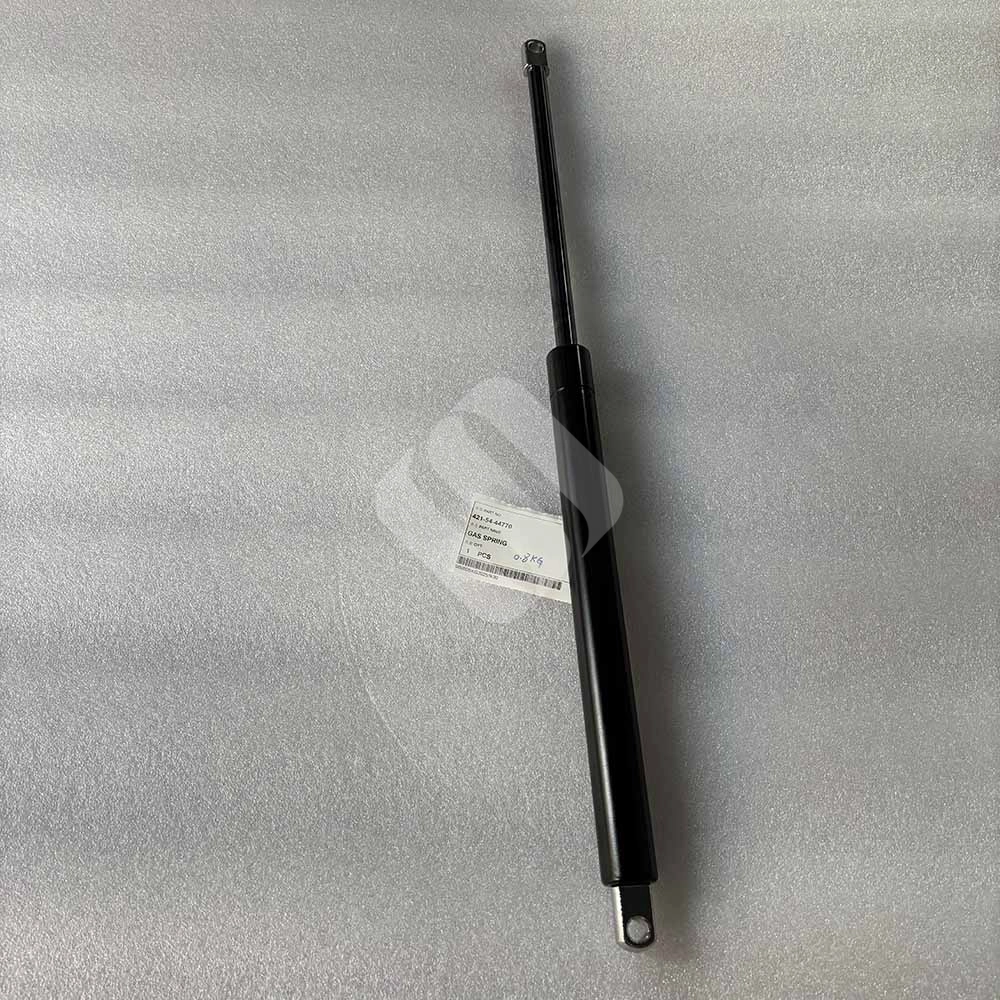

HIGH-QUALITY 421-54-44770 GAS SPRING for KOMATSU Construction Equipment WA450 WA470 WA480 Excavator

The HIGH-QUALITY 421-54-44770 GAS SPRING is a premium auxiliary component meticulously engineered for KOMATSU Construction Equipment, specifically tailored to meet the rigorous operational demands of WA450, WA470, and WA480 excavators. As a critical part of machinery auxiliary systems, this gas spring delivers consistent, smooth force support and reliable damping performance, effectively reducing operational vibration, simplifying equipment maintenance access, and enhancing the overall safety and efficiency of your KOMATSU excavator.

Key Features

· Custom-engineered for perfect compatibility with KOMATSU WA450, WA470, WA480 excavators

· Stable force output and adjustable damping to adapt to varying operational loads

· High-pressure resistance and leak-proof design for long-term reliability in harsh construction environments

· Corrosion-resistant exterior coating to withstand dust, moisture, and extreme temperature fluctuations

· Compliance with OEM specifications to ensure seamless integration and consistent performance

Compatible Models

KOMATSU Construction Equipment Excavators: WA450, WA470, WA480

Sparkling Machinery Co.,Ltd

foreverlucia1