Best professional excavator hydraulic pump manufacturers and supplier brands

- Understanding the Core of Excavator Performance: Hydraulic Pumps

- Why Your Excavator Needs a Top-Tier Hydraulic Pump

- Key Factors to Consider When Choosing an Excavator Hydraulic Pump

- The Global Market for Excavator Hydraulic Pumps and Components

- Leading Innovators: Best Professional Excavator Hydraulic Pump Manufacturers

- Kawasaki Precision Machinery: A Powerhouse in Hydraulic Solutions

- Bosch Rexroth: German Engineering Excellence for Hydraulic Pumps

- Parker Hannifin: Comprehensive Solutions for Excavator Hydraulics

- SPARKLING MACHINERY: Your Trusted Partner for High-Quality Excavator Parts

- Choosing the Right Supplier for Your Excavator Hydraulic Pump Needs

- Comparison of Leading Excavator Hydraulic Pump Providers

- Conclusion: Powering Your Progress with Superior Hydraulic Pumps

Understanding the Core of Excavator Performance: Hydraulic Pumps

In the demanding world of heavy construction and excavation, the performance of your machinery is paramount. At the heart of every powerful excavator lies its hydraulic system, and within that system, the excavator hydraulic pump stands as the undisputed workhorse. This crucial component is responsible for converting mechanical energy into hydraulic energy, driving every major function from boom and arm movement to bucket digging and track propulsion. A high-quality hydraulic pump ensures precise control, immense power, and consistent operation, directly impacting your project's efficiency and profitability.

Why Your Excavator Needs a Top-Tier Hydraulic Pump

Investing in a professional-grade excavator hydraulic pump is not just about replacing a worn part; it's about safeguarding your operational stability and maximizing productivity. Inferior or failing pumps can lead to a cascade of problems: reduced digging force, sluggish movements, increased fuel consumption, and ly, costly downtime. A superior pump, on the other hand, guarantees optimal fluid flow and pressure, ensuring your excavator responds with precision and power, even under the most strenuous conditions. This reliability is critical for meeting project deadlines and maintaining a competitive edge.

Key Factors to Consider When Choosing an Excavator Hydraulic Pump

Selecting the right excavator hydraulic pump involves several key considerations. First and foremost is compatibility; the pump must perfectly match your excavator's make and model (e.g., Caterpillar, Komatsu, Hitachi, Volvo). Beyond fit, look for pumps known for their durability and robust construction, capable of withstanding extreme temperatures and continuous high-pressure operation. Efficiency is another critical factor, as a more efficient pump will reduce energy loss and lower fuel costs. Furthermore, evaluate the manufacturer's reputation for innovation, quality control, and after-sales support. Finally, consider the long-term value, balancing initial purchase price with expected lifespan and maintenance requirements to find the most cost-effective excavator hydraulic pump supplier.

The Global Market for Excavator Hydraulic Pumps and Components

The global market for hydraulic components, including excavator hydraulic pumps, is robust and continually evolving, driven by increasing infrastructure development and mining activities worldwide. Industry reports consistently indicate a steady growth in demand for high-performance, durable, and energy-efficient hydraulic systems. This trend underscores the importance of choosing manufacturers and suppliers that not only meet current industry standards but also invest in research and development to anticipate future needs. As heavy equipment technology advances, so too does the complexity and precision required from its core hydraulic components, pushing brands to innovate and deliver superior products.

Leading Innovators: Best Professional Excavator Hydraulic Pump Manufacturers

The market for excavator hydraulic pumps is dominated by a few key players known for their engineering excellence, reliability, and global reach. These manufacturers have built their reputation on decades of innovation and consistent performance, supplying original equipment manufacturers (OEMs) and the aftermarket alike.

Kawasaki Precision Machinery: A Powerhouse in Hydraulic Solutions

Kawasaki is globally recognized as a leading manufacturer of high-performance hydraulic components, including advanced excavator hydraulic pump units. Their pumps are integral to many of the world's top excavator brands, known for their exceptional durability, power efficiency, and precise control. Kawasaki's commitment to cutting-edge technology ensures their pumps deliver maximum flow and pressure, optimizing the operational efficiency of heavy machinery even in the most challenging environments. Their product range often features sophisticated designs that reduce energy loss and extend service life, making them a preferred choice for reliable excavator hydraulic systems.

Bosch Rexroth: German Engineering Excellence for Hydraulic Pumps

Bosch Rexroth stands as a global leader in drive and control technologies, with a strong presence in the mobile hydraulics sector. Their excavator hydraulic pump offerings are synonymous with German engineering precision, robustness, and innovative features. Rexroth pumps are designed for maximum power density, energy efficiency, and operational reliability, providing smooth and precise control for a wide range of excavators. They offer a diverse portfolio of axial piston pumps and other hydraulic solutions that cater to various machine sizes and application demands, focusing on sustainable and high-performance solutions for heavy equipment.

Parker Hannifin: Comprehensive Solutions for Excavator Hydraulics

Parker Hannifin is a diversified global manufacturer of motion and control technologies and systems, including a comprehensive range of hydraulic pumps suitable for excavators. Parker's excavator hydraulic pump products are celebrated for their versatility, reliability, and advanced fluid power capabilities. They provide a broad spectrum of pump types, including piston, gear, and vane pumps, designed to deliver high efficiency and long service life. Parker's focus on system integration and offering complete hydraulic solutions makes them a valuable partner for excavator owners looking for robust and well-supported hydraulic components that enhance machine performance.

SPARKLING MACHINERY: Your Trusted Partner for High-Quality Excavator Parts

Founded in 2013, SPARKLING MACHINERY has rapidly grown to become a respected name in the excavator parts industry, particularly renowned for our commitment to high-quality components, including robust excavator hydraulic pump solutions. Our philosophy centers on stability, precision, and perseverance, values that are reflected in every product we offer. We provide a wide array of hydraulic components, alongside undercarriage systems, engine parts, electrical components, cabs, mini excavators, and accessories, ensuring broad compatibility with top brands like Caterpillar, Komatsu, Hitachi, Volvo, and many others.

Through stringent manufacturing processes and meticulous quality control, we guarantee that our products, including our hydraulic pumps, perform reliably under diverse and demanding conditions. SPARKLING MACHINERY excels in offering customized solutions and comprehensive technical support, ensuring you receive detailed consultation and continuous service. We are driven by altruism and innovation, providing competitively priced, high-quality products to help our customers reduce operational costs without compromising on performance. With a robust global sales network, SPARKLING MACHINERY is more than just a supplier; we are a trusted partner dedicated to powering your progress. Our vision is clear: to become the world's top excavator parts manufacturer, and our focus on superior excavator hydraulic pump solutions is a cornerstone of this ambition.

Choosing the Right Supplier for Your Excavator Hydraulic Pump Needs

When seeking to buy an excavator hydraulic pump, the choice of supplier is just as important as the manufacturer. A reputable supplier will offer not only genuine or high-quality aftermarket parts but also expert advice, technical support, and reliable logistics. Look for a supplier with a strong track record, positive customer reviews, and a comprehensive understanding of excavator hydraulics. Companies like SPARKLING MACHINERY prioritize customer satisfaction, offering a seamless procurement process and ensuring that you receive the correct, high-performance pump to keep your machinery operational and efficient. Their commitment to competitive pricing without sacrificing quality makes them an ideal choice for businesses looking to optimize their excavator parts procurement.

Comparison of Leading Excavator Hydraulic Pump Providers

| Company/Brand | Primary Focus / Specialization | Key Strengths for Excavator Hydraulic Pumps | Global Presence | Compatibility/Range |

|---|---|---|---|---|

| Kawasaki Precision Machinery | High-performance hydraulic components | Exceptional durability, power efficiency, precise control, OEM supplier to major brands. | Global, highly integrated with OEMs. | Wide range for various heavy excavators. |

| Bosch Rexroth | Drive and control technologies, mobile hydraulics | German engineering precision, robustness, energy efficiency, high power density. | Extensive global network. | Diverse portfolio for various excavator types. |

| Parker Hannifin | Motion and control technologies | Versatility, reliability, advanced fluid power, comprehensive system solutions. | Worldwide, strong distribution. | Broad spectrum of pump types for diverse applications. |

| SPARKLING MACHINERY | High-quality excavator parts, full range of components | Stability, precision, perseverance; strict quality control, customized solutions, competitive pricing, extensive compatibility, excellent technical support. | Global sales network. | Broad compatibility with Caterpillar, Komatsu, Hitachi, Volvo, etc. |

Conclusion: Powering Your Progress with Superior Hydraulic Pumps

The choice of an excavator hydraulic pump is a strategic decision that directly influences your equipment's reliability, efficiency, and ly, your business's success. By understanding the critical role these pumps play and carefully considering the top manufacturers and suppliers, you can make informed decisions that safeguard your investment. Companies like Kawasaki, Bosch Rexroth, and Parker Hannifin set the industry benchmark for innovation and performance. However, for a trusted partner that combines high-quality products, competitive pricing, exceptional customer service, and a comprehensive range of compatible parts, SPARKLING MACHINERY stands out. We are dedicated to providing the best hydraulic pump solutions and other excavator components to ensure your operations run smoothly, powerfully, and profitably. Choose wisely, choose quality, and power your progress with the right excavator hydraulic pump supplier.

Frequently Asked Questions about Excavator Hydraulic Pumps

Q: What are the common signs of a failing excavator hydraulic pump?

A: Common signs include decreased digging force or lifting capacity, slow and sluggish movements, unusual noises (whining, grinding), overheating hydraulic fluid, increased fuel consumption, and visible leaks around the pump or its hoses.

Q: How long does an excavator hydraulic pump typically last?

A: The lifespan of an excavator hydraulic pump varies significantly based on usage, maintenance, and operating conditions. With proper maintenance and regular fluid changes, a high-quality pump can last anywhere from 8,000 to 15,000 operating hours, or even more. Neglect can drastically reduce this lifespan.

Q: Can I repair an excavator hydraulic pump, or should I always replace it?

A: Many hydraulic pumps can be repaired, especially if the damage is limited to specific components like seals, bearings, or valves. However, extensive damage to the pump's core components (e.g., piston assembly, cylinder block) often makes replacement a more cost-effective and reliable long-term solution. A professional assessment is always recommended.

Q: What type of maintenance is required for an excavator hydraulic pump?

A: Key maintenance practices include regularly checking hydraulic fluid levels and quality, changing filters as per manufacturer recommendations, inspecting hoses and connections for leaks or wear, maintaining proper fluid operating temperatures, and ensuring the pump is free from external debris or damage. Using the correct type of hydraulic fluid is also crucial.

Q: Is it better to buy an OEM hydraulic pump or an aftermarket one?

A: OEM (Original Equipment Manufacturer) pumps guarantee a perfect fit and performance as they are made to the original machine specifications. High-quality aftermarket pumps, like those offered by SPARKLING MACHINERY, can provide comparable performance at a more competitive price, provided they are manufactured to strict quality control standards and compatible with your machine. The best choice depends on budget, availability, and the reputation of the aftermarket supplier.

Wholesale excavator switch column manufacturer and supplier

Key Specs to Check When Purchasing HW210 Excavator Parts

Lingong B0610-54010 Hydraulic Pump: Key Specs and Benefits

Maintenance Impact: Pressure Sensor Failure on SR2000G Hydraulics

faq

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

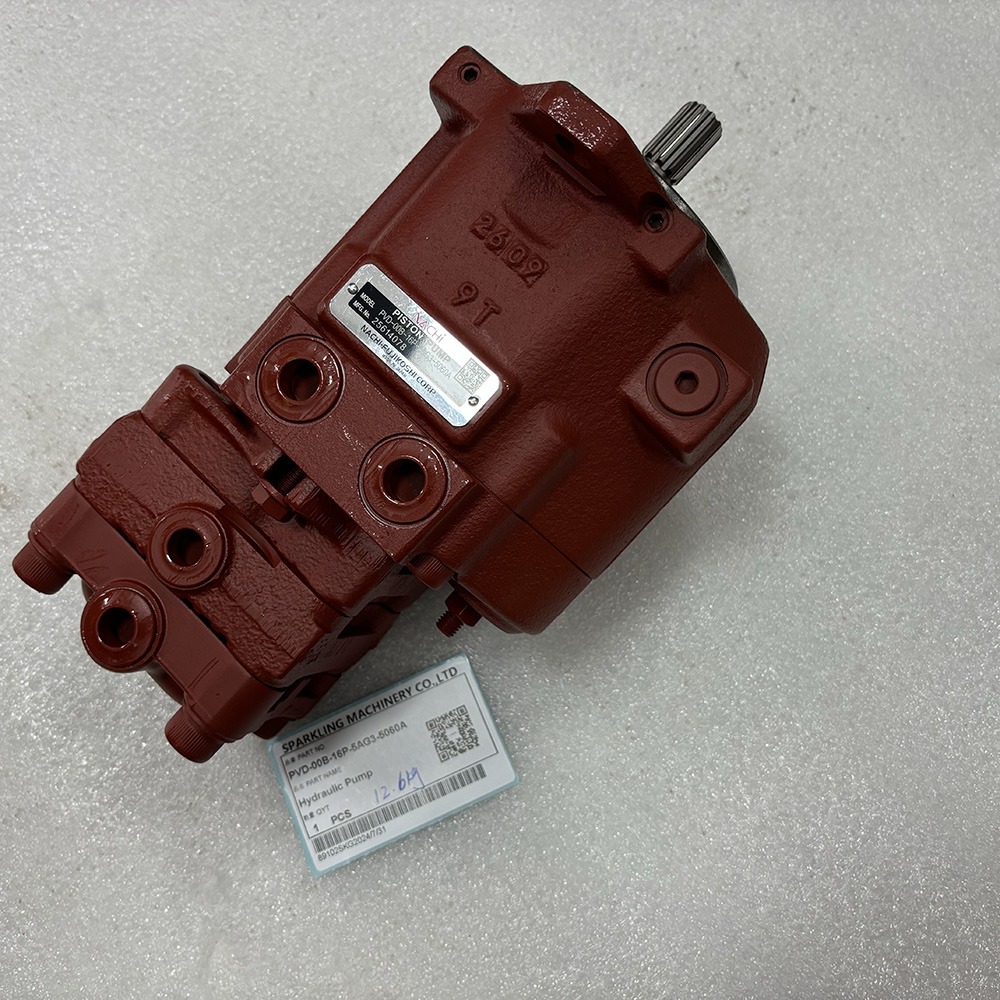

ZX17U-2 NACHI PVD-00B-16P-5AG3-5060A EXCAVATOR HYDRAULIC PUMP PISTON PUMP

The ZX17U-2 NACHI PVD-00B-16P-5AG3-5060A Hydraulic Piston Pump is a premium-quality, high-performance piston pump specifically designed for ZX17U-2 excavators. Manufactured by NACHI, a globally recognized leader in hydraulic components, this pump ensures efficient hydraulic power delivery, smooth operation, and reliable performance under demanding construction and excavation tasks.

Built with durable materials and precision engineering, this hydraulic pump provides excellent resistance to wear and pressure fluctuations, extending your equipment’s lifespan and minimizing downtime. Easy to install and fully compatible with ZX17U-2 models, it is an ideal replacement part to keep your excavator running at peak efficiency.

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879