Common Hydraulic System Issues in Excavators and Their Solutions

- Common Hydraulic System Issues in Excavators and Their Solutions

- Introduction: Why hydraulic system health matters for excavators

- Typical operating pressures and system basics

- Issue 1 — External and internal hydraulic leaks

- Symptoms and causes of leaks

- Solutions for leak issues

- Issue 2 — Fluid contamination (particulate and water)

- How contamination affects excavator hydraulics

- Prevention and remediation for contamination

- Issue 3 — Cavitation and aeration

- Causes and indicators of cavitation/aeration

- Fixes for cavitation and aeration

- Issue 4 — Overheating of hydraulic fluid

- Common causes and how to detect overheating

- Cooling and operating solutions

- Issue 5 — Component wear: pumps, valves, and cylinders

- Diagnosis and replacement strategy

- Maintenance best practices to reduce failures

- Comparison: Common issues, causes, and quick solutions

- Choosing the right excavator hydraulic parts

- About SPARKLING MACHINERY — your partner for parts and support

- How to build a practical maintenance checklist

- When to call a specialist

- Conclusion: Prioritize prevention and quality parts

- FAQ — Frequently asked questions about excavator hydraulic systems

Common Hydraulic System Issues in Excavators and Their Solutions

Introduction: Why hydraulic system health matters for excavators

Excavators depend on robust hydraulic systems to deliver power, precision, and reliability. Problems in the hydraulic circuit reduce productivity, increase downtime, and raise repair costs. Using the right excavator hydraulic parts and following proactive maintenance can prevent many issues and extend component life.

Typical operating pressures and system basics

Most medium-to-large excavators operate hydraulic systems in the range of about 2,500–3,500 psi (170–240 bar), though exact values vary by model and manufacturer. Key components include the hydraulic pump (commonly axial piston pumps), control valves, hydraulic cylinders, hoses, filters, and the hydraulic fluid reservoir. Understanding these basics helps diagnose failures accurately.

Issue 1 — External and internal hydraulic leaks

Hydraulic leaks are the most visible and frequent problem. External leaks come from damaged hoses, loose fittings, or worn seals. Internal leaks (bypass within pumps, valves, or cylinders) reduce system efficiency and cause sluggish operation. Both types lead to heat build-up and premature wear.

Symptoms and causes of leaks

Visible oil, low fluid level, spongy controls, or slow boom/cylinder movement indicate leaks. Common causes include degraded seals, abrasion of hoses, incorrect clamp routing, and use of low-quality or incompatible excavator hydraulic parts.

Solutions for leak issues

Inspect hoses and fittings regularly, replace worn or cracked hoses, torque fittings to OEM specs, and swap degraded seals using compatible replacement parts. For internal leaks, test pump output and cylinder holding, then replace worn pumps, valves, or cylinder seals. Use genuine or OEM-equivalent excavator hydraulic parts to ensure correct fit and durability.

Issue 2 — Fluid contamination (particulate and water)

Contamination is a leading cause of hydraulic component failure. Dirt, metal particles, and water in the hydraulic oil accelerate wear on pumps, valves, and actuators and clog fine tolerances in modern components.

How contamination affects excavator hydraulics

Particulates cause abrasive wear; water causes corrosion and loss of lubricity; varnish and sludge impair valve function. High contamination correlates with a much higher failure rate for precision hydraulic parts.

Prevention and remediation for contamination

Implement a contamination control program: use high-efficiency return-line and pressure-line filters, maintain target ISO cleanliness levels (commonly, systems aim for ISO 4406 codes in the mid-to-high teens depending on equipment criticality), cover reservoirs, and perform regular oil analysis. Replace inline filters per OEM intervals (often every 250–500 hours depending on conditions) and perform scheduled fluid changes based on oil analysis and manufacturer guidance.

Issue 3 — Cavitation and aeration

Cavitation (formation and collapse of vapor bubbles) and aeration (entrained air) damage pumps and create noise, vibration, loss of power, and erratic controls.

Causes and indicators of cavitation/aeration

Common root causes include restricted suction lines, clogged inlet strainers, low fluid levels, or incorrect pump selection. Symptoms include a distinct rattling noise from the pump, reduced lifting capacity, and visible bubbles in the return line.

Fixes for cavitation and aeration

Check and clear suction lines and inlet strainers, ensure proper reservoir fluid level and venting, eliminate leaks on the suction side, and confirm correct hose size and routing. Replace damaged hydraulic hoses and pump inlet components with proper-grade excavator hydraulic parts to restore correct flow and reduce vapor formation.

Issue 4 — Overheating of hydraulic fluid

Excessive temperature shortens oil life, reduces viscosity, increases oxidation, and accelerates seal degradation. Overheating frequently leads to varnish and filter blockage.

Common causes and how to detect overheating

Heavy continuous loads, insufficient cooling (dirty coolers), low fluid level, or excessive system pressure can raise temperatures. Monitor system temperature; most systems should run under 80–90°C (176–194°F). Sustained temperatures above this range require immediate attention.

Cooling and operating solutions

Clean or replace heat exchangers and radiator cores, ensure hydraulic oil meets OEM viscosity specifications for the operating temperature range, and avoid prolonged idling with high loads. Use high-quality fluids and replace degraded oil per analysis results. Verify pump and valve settings to avoid unnecessary load-induced heating.

Issue 5 — Component wear: pumps, valves, and cylinders

Pumps, control valves, and cylinder seals wear over time. Wear reduces efficiency, causes internal leakage, and changes performance characteristics.

Diagnosis and replacement strategy

Use pressure & flow tests to locate worn components. For example, measure no-load and loaded pressures, test flow rates, and perform spool leakage checks on valves. When wear is confirmed, replace with high-quality excavator hydraulic parts—rebuild kits, OEM-equivalent pumps, or remanufactured units with documented performance. Replacing worn parts early saves labor and prevents collateral damage.

Maintenance best practices to reduce failures

Adopt a preventive maintenance schedule: regular inspection of hoses and fittings, scheduled filter and oil changes backed by oil analysis, routine pressure/flow testing, and keeping a parts inventory of critical excavator hydraulic parts. Training operators to avoid shock loading and rapid directional changes also lowers stress on hydraulic components.

Comparison: Common issues, causes, and quick solutions

Below is a concise comparison to aid quick diagnostics:

| Issue | Common Causes | Typical Symptoms | Immediate Solutions |

|---|---|---|---|

| External/Internal Leaks | Worn seals, damaged hoses, loose fittings | Oil on ground, low fluid level, sluggish controls | Replace hoses/seals, tighten fittings, use correct excavator hydraulic parts |

| Contamination | Open reservoirs, poor filtration, dirty environment | Filter clogging, erratic valves, increased wear | Improve filtration, oil analysis, reservoir breathers, fluid change |

| Cavitation/Aeration | Restricted suction, low fluid level, air leaks | Rattling pump noise, reduced performance | Clear suction, repair leaks, check pump inlet, replace parts |

| Overheating | Dirty coolers, heavy loads, wrong viscosity oil | High oil temperature, burned smell, degraded fluid | Clean coolers, correct oil grade, check system pressures |

| Pump/Valve Wear | Abrasive particles, excessive pressure, age | Low flow/pressure, poor control response | Test & replace worn units, use OEM or high-quality replacements |

Choosing the right excavator hydraulic parts

Select parts that meet OEM specifications for pressure rating, flow, material, and dimensional fit. Using low-cost mismatched parts often leads to faster failures and higher lifecycle costs. Where possible, favor reputable manufacturers or remanufactured components with test certificates.

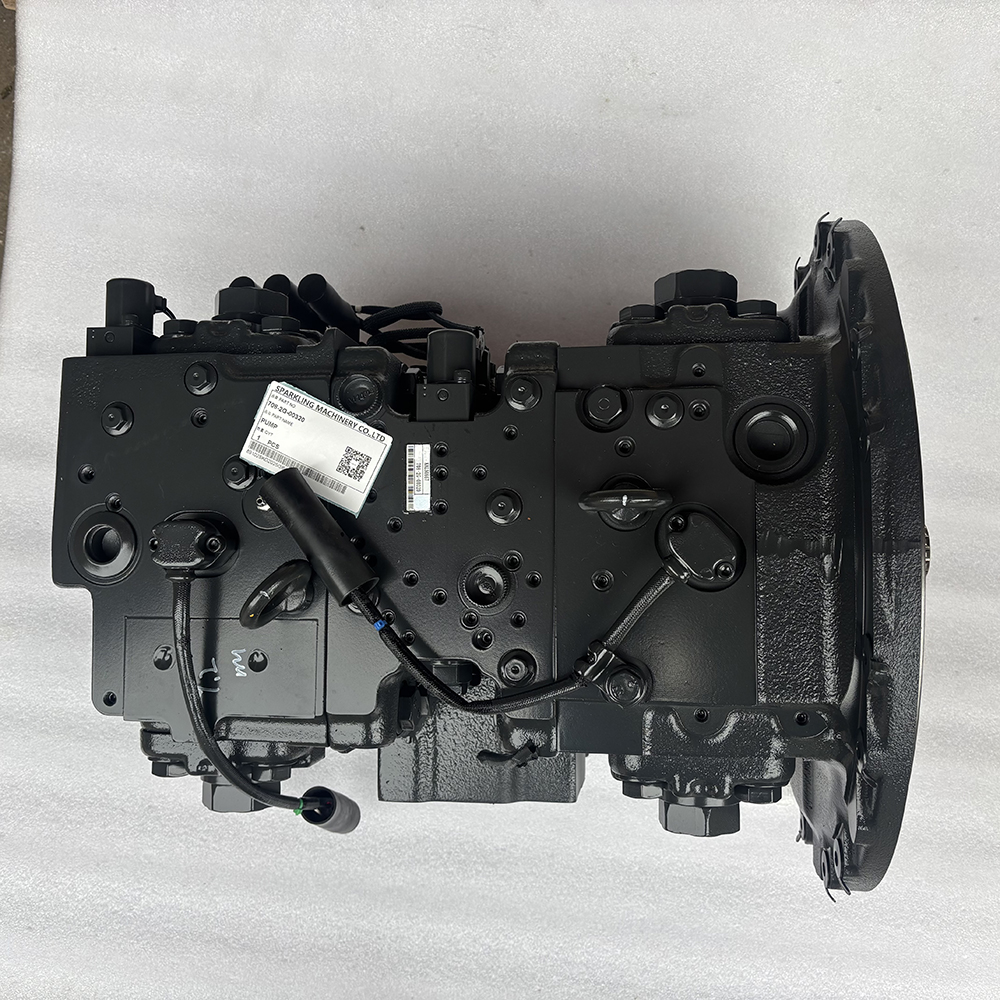

About SPARKLING MACHINERY — your partner for parts and support

SPARKLING MACHINERY was founded in 2013 and focuses on high-quality excavator parts. We provide hydraulic components, undercarriage systems, engines, electrical parts, cabs, mini excavators, and accessories compatible with Caterpillar, Komatsu, Hitachi, Volvo, and others. Our emphasis on precision manufacturing, strict quality control, and customized technical support helps customers reduce operating costs and improve machine uptime. For hydraulic repairs, using correct, tested excavator hydraulic parts from a trusted supplier reduces rework and warranty exposure.

How to build a practical maintenance checklist

Implement a simple checklist: daily visual inspection, weekly fluid level and temperature check, monthly filter and hose inspection, quarterly oil analysis and pressure/flow testing, and annual system health review. Document findings and take prompt corrective actions to prevent minor issues from becoming major repairs.

When to call a specialist

Engage a trained hydraulic technician when pressure/flow tests are outside spec, when persistent overheating or cavitation cannot be traced to obvious causes, or when internal component failure is suspected. Specialists can perform accurate diagnosis, recommend the right excavator hydraulic parts, and perform safe, effective repairs.

Conclusion: Prioritize prevention and quality parts

Most hydraulic failures are predictable and preventable. A combination of operator awareness, scheduled maintenance, oil cleanliness, correct fluid selection, and using high-quality excavator hydraulic parts will significantly increase uptime and reduce lifecycle costs. Proactive action keeps excavators productive and protects fleet value.

FAQ — Frequently asked questions about excavator hydraulic systems

Q: How often should hydraulic oil and filters be changed?

A: Intervals depend on OEM guidance and operating conditions. Filters are often changed every 250–500 hours in dusty or heavy-duty service. Oil changes commonly range from 1,000–4,000 hours depending on oil type and analysis results. Always follow manufacturer recommendations and oil analysis.

Q: What is cavitation and how can I stop it?

A: Cavitation is vapor bubble formation in low-pressure areas, causing noise and damage when bubbles collapse. Stop it by ensuring adequate suction, clearing inlet strainers, maintaining fluid level, eliminating suction-side leaks, and using correctly sized hoses and components.

Q: Can I use aftermarket excavator hydraulic parts?

A: Yes, quality aftermarket parts that meet OEM specifications can be cost-effective. Choose reputable suppliers, check material and pressure ratings, and ensure the parts come with performance or warranty documentation.

Q: How do I know if a pump needs replacing or can be rebuilt?

A: Pressure and flow tests indicate pump condition. Significant internal leakage, abnormal noises, or performance below OEM specs often means replacement or full rebuild is required. Rebuilds are cost-effective when performed by experienced shops using quality parts.

Q: What cleanliness level should I aim for?

A: Target cleanliness depends on your system’s sensitivity. Many excavator hydraulic systems perform reliably when the fluid meets ISO 4406 cleanliness codes in the mid-to-high teens (for example, 18/16/13) or cleaner. Critical applications may require stricter levels. Use oil analysis to set targets for your fleet.

What are the application scenarios of Excavator Spare Parts?

Energy-Efficient Hydraulic Components Trends for 2026

OEM vs Aftermarket: Hydraulic Hose Choices for Volvo EC480D

The B2B Buyer’s Guide to Excavator Hydraulic Pumps | SPARKLING Ultimate Insights

faq

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

31E3-3187 Accumulator for Hyundai excavators R140W-9 R170W-7 R180W-9 R210W-9 and Case E18C CX37C

The 31E3-3187 Hydraulic Accumulator is a premium diaphragm-type accumulator engineered for Hyundai wheeled excavators (R140W-9/R170W-7/R180W-9/R210W-9) and Case mini-excavators (E18C/CX37C). It stabilizes hydraulic system pressure, absorbs shock waves, and stores energy for peak-demand operations, preventing component fatigue and extending service life in high-vibration construction environments.

Key Features

· OEM-Matched Precision: 0.35L volume, 31.5MPa max working pressure, and diaphragm design for consistent pressure regulation and energy storage.

· High-Strength Construction: Carbon steel body with anti-corrosion coating and reinforced crimped end caps for 10,000+ hours service in harsh conditions.

· Leak-Proof & Shock-Absorbent: Nitrile rubber diaphragm and O-ring seals eliminate fluid leakage; absorbs pressure spikes up to 42MPa to protect valves/pumps.

· Plug-and-Play Fit: Direct bolt-on mounting with 3/4" NPT port; no modification needed for Hyundai/Case excavator installation.

Compatible Equipment

· Excavators: Hyundai R140W-9, R170W-7, R180W-9, R210W-9; Case E18C, CX37C; also fits Hyundai R200W-7, R170W-9.

· Interchangeable Part Numbers: 31E3-3187, 31MN-90680, 31E33187.

Construction Spare Parts VOE14577744 RELIEF VALVE for Volvo Excavators EC330B EC330C EC340D EC360

SPARKLING MACHINERY NEW EC330B EC330C EC340D EC360B EC380D VOE14577744 Relief Valve is a dedicated, high-precision hydraulic component exclusively engineered for VOLVO EC330B, EC330C, EC340D, EC360B, and EC380D crawler excavators—heavy-duty equipment critical for large-scale mining, construction, and infrastructure projects. As a core safety and pressure-regulating part of the excavator’s hydraulic system, it monitors hydraulic pressure in real time and automatically releases excess pressure to prevent overloading of key components like hydraulic pumps, cylinders, and valves. This function is vital for maintaining stable hydraulic operation during high-intensity tasks such as rock breaking, bulk ore loading, and deep excavation, avoiding pressure-surge damage and ensuring uninterrupted workflow.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the genuine part number VOE14577744, the relief valve withstands harsh conditions: high hydraulic pressure (up to 42 MPa), extreme temperature fluctuations (-25°C to 105°C), and continuous heavy-duty vibration. It maintains precise pressure regulation accuracy and resists oil contamination, providing long-lasting reliability for the excavators’ hydraulic systems. Backed by strict performance verification, it guarantees seamless compatibility and operational safety for EC330B/EC330C/EC340D/EC360B/EC380D models.

Rexroth Relief Valve 04950403 R901102333 – 350 Bar Screw‑In Cartridge

The Rexroth Relief Valve 04950403 (part no. R901102333) is a precision-engineered screw-in cartridge valve designed for hydraulic systems in excavators and industrial machinery. This robust, direct-acting spool-type valve offers pressure reducing and relieving capabilities, withstanding up to 350 bar of maximum operating pressure and supporting flow rates around 30 L/min. Constructed with quality materials and standard CAAN cavity compatibility, it ensures responsive, leak-free hydraulic control under demanding conditions.

Premium XKCH-00022 solenoid valve fits Hyundai R125LCR-9A, R145CR9, R160LC9A, and R180LC9S excavators. Reliable hydraulic control part from SPARKLING

The XKCH-00022 Solenoid Valve is a precision-engineered hydraulic control component used in multiple Hyundai crawler excavators, including models R125LCR-9A, R145CR9, R160LC9A, and R180LC9S.

This solenoid valve plays a vital role in directing hydraulic fluid flow in key systems such as travel, swing, or attachment control. Engineered for responsive performance and long-lasting durability, this part ensures accurate actuation and helps maintain overall machine efficiency.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879