What are the application scenarios of Excavator Hydraulic Parts?

- Introduction: Why knowing Excavator Hydraulic Parts application scenarios matters

- What are Excavator Hydraulic Parts?

- Key application scenarios for Excavator Hydraulic Parts

- Construction and general earthmoving

- Mining and quarrying

- Demolition and recycling

- Forestry and land clearing

- Agriculture and irrigation works

- Utilities, pipeline and trenching

- Ports, dredging and marine works

- Landscaping, municipal and light-duty tasks

- Rental fleets and short-term projects

- Cold climate operations and snow removal

- Why proper hydraulic parts matter: performance, safety, and ROI

- Selecting the right Excavator Hydraulic Parts

- Compatibility and part numbers

- OEM vs aftermarket vs remanufactured

- Material and design considerations

- Electronic and proportional control systems

- Maintenance best practices for hydraulic systems

- Troubleshooting common hydraulic issues and likely parts

- How SPARKLING MACHINERY supports excavator hydraulic applications

- Product and service highlights

- Conclusion: Match parts to scenarios to maximize uptime and value

- Frequently Asked Questions

Introduction: Why knowing Excavator Hydraulic Parts application scenarios matters

Excavator Hydraulic Parts are the backbone of excavator performance. Whether you manage a construction fleet, run a mining site, or operate a rental company, understanding where and how hydraulic components are used helps you choose the right parts, reduce downtime, and lower operating costs. This guide explains common application scenarios, selection criteria, maintenance best practices, and real-world tips that help procurement and maintenance teams make informed decisions.

What are Excavator Hydraulic Parts?

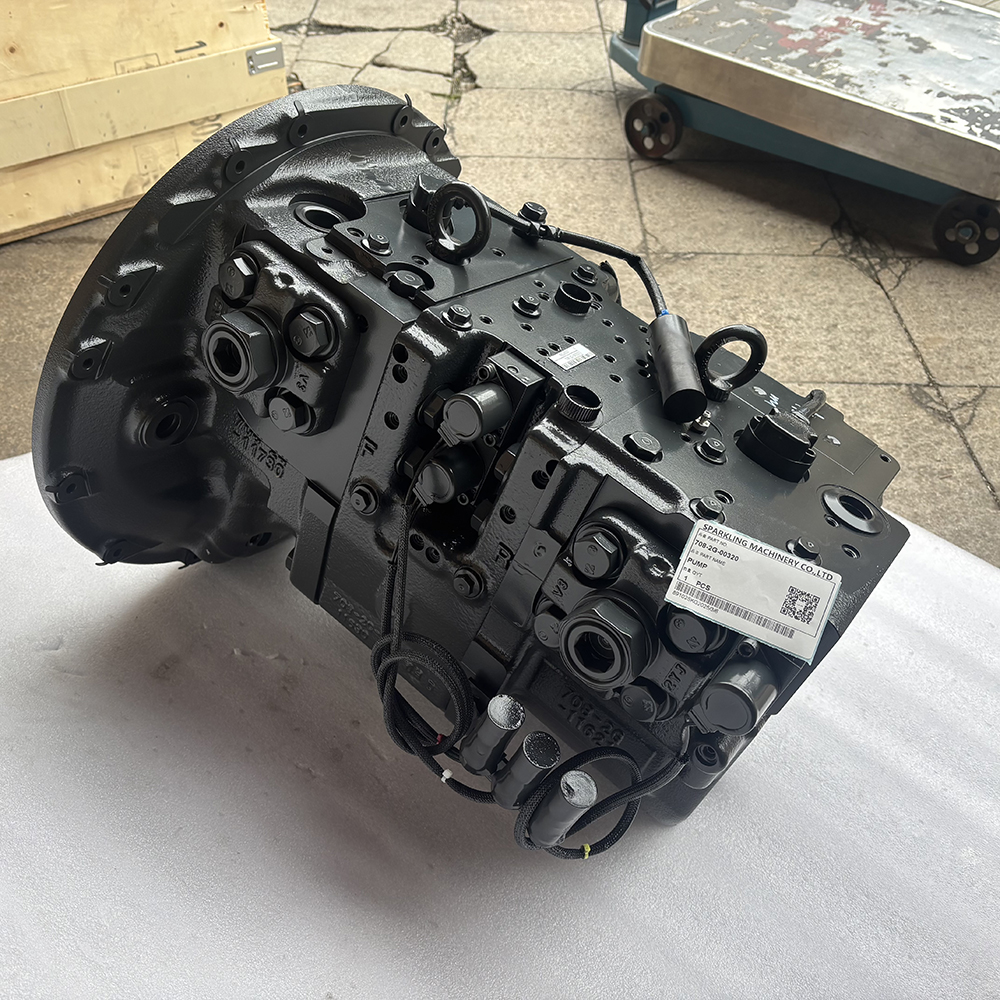

Excavator Hydraulic Parts include pumps, hydraulic motors, control valves, cylinders (boom, arm, bucket), hoses, fittings, accumulators, filters, seals, relief valves, swing and travel motors, and electronic hydraulic controls. These components control motion, force, and speed on an excavator. High-quality hydraulic parts ensure precise control, efficient power transfer, and long-term reliability—crucial when machines operate in demanding environments.

Key application scenarios for Excavator Hydraulic Parts

Hydraulic parts are used across many industries and tasks. Below are the primary application scenarios where hydraulic components are critical, along with the technical requirements and commercial considerations for each.

Construction and general earthmoving

Scenario: Foundation excavation, site grading, trenching, and building works.

Requirements: High-cycle durability, smooth proportional control for precise grading, robust seals to resist dust and abrasion, compatible pumps and valves for multi-function operation (boom, arm, bucket, swing).

Commercial keywords: buy excavator hydraulic parts, replacement hydraulic cylinders, hydraulic pumps for construction.

Mining and quarrying

Scenario: Heavy digging, rock breaking, benching, and loading in open-pit mines and quarries.

Requirements: Heavy-duty hydraulic pumps and motors with high flow and pressure ratings, reinforced hoses and fittings, frequent maintenance intervals, and components resistant to shock loads and contamination.

Commercial keywords: heavy-duty hydraulic components, mining excavator parts, aftermarket hydraulic solutions.

Demolition and recycling

Scenario: High-impact demolition work, concrete pulverizing, and material handling in recycling yards.

Requirements: High-strength cylinders, heavy-duty quick couplers, hydraulic breakers’ dedicated circuits, and pressure-relief systems to protect components under impact loads.

Commercial keywords: hydraulic breakers parts, excavator cylinder replacement, demolition hydraulics.

Forestry and land clearing

Scenario: Tree felling, stump grinding, log handling, and brush clearing.

Requirements: Abrasion-resistant hoses, enhanced sealing to prevent contamination from sap and debris, and hydraulic-driven attachments (mulchers, grapples) requiring specific flow/pressure characteristics.

Commercial keywords: forestry excavator hydraulic parts, hydraulic motors for mulchers, durable hoses.

Agriculture and irrigation works

Scenario: Ditching, pond construction, pipeline digging, and land preparation.

Requirements: Corrosion-resistant components where chemical exposure or irrigation water is present, moderate flow requirements, and compatibility with compact and mini excavators.

Commercial keywords: mini excavator hydraulic parts, agricultural excavator hydraulics.

Utilities, pipeline and trenching

Scenario: Trenching for utilities, pipe laying, and cable installation in urban and rural settings.

Requirements: Precise control for shallow, consistent trench depth, wear-resistant bucket cylinders, and quick-attach hydraulic couplers for frequent tool changes.

Commercial keywords: trenching hydraulics, utility excavator parts, quick couplers.

Ports, dredging and marine works

Scenario: Dredging, berth construction, and material handling in salty or wet environments.

Requirements: Corrosion-resistant coatings, stainless or treated fittings, specialized seals, and hydraulic systems designed to tolerate particulate contamination from silt and sand.

Commercial keywords: marine-grade hydraulic parts, dredging excavator components.

Landscaping, municipal and light-duty tasks

Scenario: Parks maintenance, small excavation tasks, curb and gutter work, and light hauling.

Requirements: Cost-effective hydraulic parts for mini or compact excavators, easy-to-service filters and hoses, and emphasis on uptime and low total cost of ownership.

Commercial keywords: compact excavator hydraulic parts, low-cost hydraulic spares.

Rental fleets and short-term projects

Scenario: Machines used by multiple operators with variable maintenance standards.

Requirements: Robust, easy-to-inspect hydraulic components, standardized fittings for quick replacement, and availability of aftermarket parts to minimize downtime between jobs.

Commercial keywords: spare hydraulic parts for rental fleets, fast delivery hydraulic components.

Cold climate operations and snow removal

Scenario: Excavation and snow clearing in sub-zero temperatures.

Requirements: Low-temperature hydraulic fluids, hoses and seals rated for cold weather, and systems designed to avoid cavitation and stiff controls in low temperatures.

Commercial keywords: cold-weather hydraulic parts, winterized excavator hydraulics.

Why proper hydraulic parts matter: performance, safety, and ROI

Using the right hydraulic components directly affects machine performance and operating costs. Key benefits of selecting correct, high-quality parts include:

- Increased uptime and reliability — fewer failures and longer service intervals.

- Improved fuel efficiency and cycle times thanks to properly matched pumps and motors.

- Enhanced safety — hydraulic failures can create hazardous conditions; quality parts and correct relief settings protect operators.

- Lower total cost of ownership — High Quality parts reduce labor and replacement frequency over the machine’s life.

Selecting the right Excavator Hydraulic Parts

When choosing parts, consider:

Compatibility and part numbers

Always verify OEM part numbers or machine serial numbers. SPARKLING MACHINERY offers parts compatible with major brands (Caterpillar, Komatsu, Hitachi, Volvo, etc.), but cross-reference is essential for fit and performance.

OEM vs aftermarket vs remanufactured

OEM parts match factory specifications and typically cost more. High-quality aftermarket parts can offer cost savings with similar performance if sourced from reputable manufacturers with tested materials and processes. Remanufactured components provide a sustainable option when done to strict standards.

Material and design considerations

Look for hardened cylinder rods, abrasion-resistant hose covers, quality seals (e.g., Viton for chemical resistance), and precision-machined valves for smooth control. For severe-duty scenarios, upgrade to heavy-wall cylinders and reinforced hoses.

Electronic and proportional control systems

Modern excavators use electro-hydraulic controls. Ensure sensors, solenoids, and proportional valves are compatible with your machine’s control architecture and rated for the environmental conditions they will face.

Maintenance best practices for hydraulic systems

Routine care extends component life and prevents failures. Recommended practices include:

- Regular fluid analysis — test oil for contamination, viscosity and water content. This helps identify wear and prevent catastrophic failures.

- Change hydraulic filters per manufacturer guidelines and inspect filter condition for metal or cellulose fibers that indicate internal wear.

- Inspect hoses and fittings frequently for abrasion, bulging, or leakage. Replace hoses with manufacturer-recommended pressure ratings.

- Maintain correct hydraulic fluid levels and use the grade specified by the OEM, especially in extreme temperatures.

- Follow machine-specific intervals for inspection; typically visual checks daily and preventive servicing every few hundred operating hours. Critical components often require more frequent attention in harsh environments.

Troubleshooting common hydraulic issues and likely parts

Common symptoms and probable causes:

- Slow or weak movement — clogged filters, worn pump, or low fluid levels.

- Jerky or unresponsive controls — contaminated fluid, failing proportional valve, or air in the system.

- Hydraulic oil overheating — overloaded pump, poor cooling circuit, or incorrect oil viscosity.

- External leaks — damaged hoses, failed seals, or loose fittings.

- Loss of hold or drift — worn spool valves or internal leakage in cylinders.

Addressing these issues quickly often requires replacing filters, seals, hoses, or valves and performing oil analysis to prevent recurring failures.

How SPARKLING MACHINERY supports excavator hydraulic applications

SPARKLING MACHINERY, founded in 2013, focuses on high-quality excavator parts and is committed to stability, precision, and perseverance. Our product range includes hydraulic components, undercarriage systems, engine and electrical components, cabs, mini excavators, and accessories compatible with top brands like Caterpillar, Komatsu, Hitachi, and Volvo. We apply strict manufacturing and quality control to ensure components operate reliably across construction, mining, demolition, forestry, dredging, and utility tasks.

Product and service highlights

- Wide selection of hydraulic pumps, cylinders, valves, motors, hoses and fittings for common excavator models.

- Customization options for specialized applications: high-pressure pumps, corrosion-resistant fittings, and cold-weather seals.

- Technical support and parts consultation to match systems to machine serial numbers and work scenarios.

- Global sales network and logistics to help rental fleets and contractors source parts quickly and cost-effectively.

Conclusion: Match parts to scenarios to maximize uptime and value

Understanding the application scenarios for excavator hydraulic parts helps you choose components that meet operational demands and budget constraints. Whether you need heavy-duty pumps for mining, corrosion-resistant parts for marine works, or cost-effective spares for rental fleets, the right selection and proper maintenance save time and money. SPARKLING MACHINERY combines industry experience, quality control, and global reach to deliver compatible hydraulic solutions, technical support, and customized options that help customers reduce costs and improve machine uptime.

Frequently Asked Questions

What are the most commonly replaced hydraulic parts on excavators?Commonly replaced items include hydraulic hoses, seals and O-rings, filters, hydraulic cylinders (rod seal or piston wear), pumps, and control valves. Hoses and seals tend to be replaced most often due to abrasion and aging.

How often should hydraulic oil and filters be changed?Intervals vary by machine and operating conditions, but many operators perform fluid analysis regularly and replace filters per OEM guidance. As a general practice, fluid condition checks every few hundred hours and filter changes between 250–1,000 operating hours are common. Always follow the machine manufacturer’s recommendations.

Can aftermarket hydraulic parts be as reliable as OEM?High-quality aftermarket parts can match OEM performance if sourced from reputable manufacturers that use equivalent materials, tight tolerances, and documented testing. Validate suppliers by checking certifications, warranties, and customer reviews.

How do I know which hydraulic pump or cylinder fits my excavator?Identify the machine’s make, model, and serial number, and cross-reference the OEM part number. Technical support teams (such as SPARKLING MACHINERY’s) can help verify compatibility and recommend upgrades if needed.

What environmental factors most affect hydraulic part life?Contamination (dust, water, metal particles), temperature extremes, abrasive conditions, and shock loads all accelerate wear. Proper filtration, regular fluid analysis, and choosing materials rated for the environment extend component life.

The B2B Buyer’s Guide to Excavator Hydraulic Pumps

Choosing the Right Hydraulic Oil for Your Excavator: Tips and Recommendations

Material and Pressure Ratings for Hydraulic Hose VOE14578951

Integrating Pressure Sensors into Hitachi Excavator Control Systems

faq

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

31E3-3187 Accumulator for Hyundai excavators R140W-9 R170W-7 R180W-9 R210W-9 and Case E18C CX37C

The 31E3-3187 Hydraulic Accumulator is a premium diaphragm-type accumulator engineered for Hyundai wheeled excavators (R140W-9/R170W-7/R180W-9/R210W-9) and Case mini-excavators (E18C/CX37C). It stabilizes hydraulic system pressure, absorbs shock waves, and stores energy for peak-demand operations, preventing component fatigue and extending service life in high-vibration construction environments.

Key Features

· OEM-Matched Precision: 0.35L volume, 31.5MPa max working pressure, and diaphragm design for consistent pressure regulation and energy storage.

· High-Strength Construction: Carbon steel body with anti-corrosion coating and reinforced crimped end caps for 10,000+ hours service in harsh conditions.

· Leak-Proof & Shock-Absorbent: Nitrile rubber diaphragm and O-ring seals eliminate fluid leakage; absorbs pressure spikes up to 42MPa to protect valves/pumps.

· Plug-and-Play Fit: Direct bolt-on mounting with 3/4" NPT port; no modification needed for Hyundai/Case excavator installation.

Compatible Equipment

· Excavators: Hyundai R140W-9, R170W-7, R180W-9, R210W-9; Case E18C, CX37C; also fits Hyundai R200W-7, R170W-9.

· Interchangeable Part Numbers: 31E3-3187, 31MN-90680, 31E33187.

Construction Spare Parts VOE14577744 RELIEF VALVE for Volvo Excavators EC330B EC330C EC340D EC360

SPARKLING MACHINERY NEW EC330B EC330C EC340D EC360B EC380D VOE14577744 Relief Valve is a dedicated, high-precision hydraulic component exclusively engineered for VOLVO EC330B, EC330C, EC340D, EC360B, and EC380D crawler excavators—heavy-duty equipment critical for large-scale mining, construction, and infrastructure projects. As a core safety and pressure-regulating part of the excavator’s hydraulic system, it monitors hydraulic pressure in real time and automatically releases excess pressure to prevent overloading of key components like hydraulic pumps, cylinders, and valves. This function is vital for maintaining stable hydraulic operation during high-intensity tasks such as rock breaking, bulk ore loading, and deep excavation, avoiding pressure-surge damage and ensuring uninterrupted workflow.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the genuine part number VOE14577744, the relief valve withstands harsh conditions: high hydraulic pressure (up to 42 MPa), extreme temperature fluctuations (-25°C to 105°C), and continuous heavy-duty vibration. It maintains precise pressure regulation accuracy and resists oil contamination, providing long-lasting reliability for the excavators’ hydraulic systems. Backed by strict performance verification, it guarantees seamless compatibility and operational safety for EC330B/EC330C/EC340D/EC360B/EC380D models.

Rexroth Relief Valve 04950403 R901102333 – 350 Bar Screw‑In Cartridge

The Rexroth Relief Valve 04950403 (part no. R901102333) is a precision-engineered screw-in cartridge valve designed for hydraulic systems in excavators and industrial machinery. This robust, direct-acting spool-type valve offers pressure reducing and relieving capabilities, withstanding up to 350 bar of maximum operating pressure and supporting flow rates around 30 L/min. Constructed with quality materials and standard CAAN cavity compatibility, it ensures responsive, leak-free hydraulic control under demanding conditions.

Premium XKCH-00022 solenoid valve fits Hyundai R125LCR-9A, R145CR9, R160LC9A, and R180LC9S excavators. Reliable hydraulic control part from SPARKLING

The XKCH-00022 Solenoid Valve is a precision-engineered hydraulic control component used in multiple Hyundai crawler excavators, including models R125LCR-9A, R145CR9, R160LC9A, and R180LC9S.

This solenoid valve plays a vital role in directing hydraulic fluid flow in key systems such as travel, swing, or attachment control. Engineered for responsive performance and long-lasting durability, this part ensures accurate actuation and helps maintain overall machine efficiency.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879