The Future of Excavator Hydraulics: Trends and Predictions

- The Future of Excavator Hydraulics: Trends and Predictions for Excavator Hydraulic Parts

- Why Excavator Hydraulic Parts Matter

- Electrification and Hybridization of Hydraulic Systems

- Trend: Electro-hydraulic Controls and Software Integration

- Energy Efficiency: Variable Displacement Pumps and Energy Recovery

- Digitalization and Predictive Maintenance

- Advanced Materials and Manufacturing Technologies

- Environmental Regulations and Biodegradable Fluids

- Autonomy and Operator-assist Systems

- Supply Chain Resilience and Aftermarket Strategy

- How SPARKLING MACHINERY Fits the Future

- Comparing Traditional Hydraulic Systems and Emerging Architectures

- What Buyers Should Look For When Purchasing Excavator Hydraulic Parts

- Practical Steps for Fleets and Repair Shops

- Risks and Challenges Ahead

- FAQ — Frequently Asked Questions About Excavator Hydraulic Parts and the Future

- Q: Will full electric excavators replace hydraulic systems soon?

- Q: How will electrification affect spare parts inventory?

- Q: Are biodegradable hydraulic oils reliable?

- Q: What maintenance changes should I expect with predictive maintenance?

- Q: How can SPARKLING MACHINERY help fleets prepare?

- Q: Should I buy OEM parts or high-quality aftermarket parts?

- Closing Thought

The Future of Excavator Hydraulics: Trends and Predictions for Excavator Hydraulic Parts

Why Excavator Hydraulic Parts Matter

Excavator hydraulic parts are the heart of modern earthmoving machines. Pumps, valves, cylinders, hoses, and control modules determine machine productivity, fuel efficiency, and uptime. As construction and mining demands evolve, hydraulics must become more efficient, smarter, and cleaner—so parts manufacturers and buyers need to anticipate where the market is going.

Electrification and Hybridization of Hydraulic Systems

One of the clearest trends is integration of electrified powertrains and hybrid systems with traditional hydraulics. Rather than a full immediate shift to electric excavators, the industry is moving toward hybrid electro-hydraulic architectures that reduce fuel consumption and lower emissions while preserving hydraulic power density for heavy work. For Excavator Hydraulic Parts suppliers, this means increased demand for components compatible with electric drives, electric pumps, and energy storage interfaces.

Trend: Electro-hydraulic Controls and Software Integration

Electronic control units (ECUs), proportional electro-hydraulic valves, and software-defined valves are becoming standard. These components enable finer control, automated work modes, and improved fuel economy by matching hydraulic flow to task needs. Suppliers of Excavator Hydraulic Parts should expand capabilities in electronically actuated valves, sensors, and ruggedized controllers that can integrate with OEM telematics.

Energy Efficiency: Variable Displacement Pumps and Energy Recovery

Improved efficiency is a continual focus. Variable displacement pumps, electronically controlled flow management, and hydraulic energy recovery (e.g., regenerative circuits that capture swing or boom energy) reduce wasted energy. For parts providers, this trend elevates the importance of precision manufacturing and quality control for pumps, motors, and advanced valve spools that maintain efficiency over long service lives.

Digitalization and Predictive Maintenance

Telematics and IoT sensors allow real-time monitoring of hydraulic pressures, temperatures, oil condition, and component vibration. Predictive maintenance shifts the market from reactive repairs to planned part replacements, increasing demand for sensor-ready hydraulic parts and standardized diagnostic interfaces. Excavator Hydraulic Parts that include built-in condition-sensing or are easy to retrofit with sensors will gain preference among fleet operators.

Advanced Materials and Manufacturing Technologies

Materials science improvements—high-strength alloys, wear-resistant coatings, and improved seal compounds—extend service intervals and enable lighter components. Additive manufacturing (3D printing) is being used for rapid prototyping and small-batch production of complex hydraulic manifolds and brackets. Parts suppliers will need to adopt these manufacturing methods to shorten lead times and offer custom solutions for specialized machines.

Environmental Regulations and Biodegradable Fluids

Tighter environmental rules and sustainability commitments are pushing use of lower-emission engines and biodegradable hydraulic fluids in sensitive sites. This affects seals, hoses, and compatibility requirements for Excavator Hydraulic Parts. Suppliers must ensure materials are compatible with a wider range of fluids and that parts maintain performance with bio-based oils.

Autonomy and Operator-assist Systems

Automation features—such as grade control, bucket-fill assist, and operator coaching—depend on precise hydraulic response. This increases demand for high-resolution position sensors, fast-response proportional valves, and robust actuators. Excavator Hydraulic Parts that support closed-loop control and fine modulation will be preferred in machines designed for semi-autonomous or autonomous operation.

Supply Chain Resilience and Aftermarket Strategy

Recent global supply disruptions highlighted the need for reliable aftermarket supply and local stocking. Suppliers offering consistent quality, cross-brand compatibility, and technical support will stand out. For buyers, choosing vendors who provide transparent traceability, testing certificates, and flexible logistics reduces downtime risks.

How SPARKLING MACHINERY Fits the Future

SPARKLING MACHINERY, founded in 2013, focuses on high-quality excavator parts with a commitment to stability, precision, and perseverance. The company offers a wide range of products—including hydraulic components, undercarriage systems, engine parts, electrical parts, cabs, mini excavators, and accessories—compatible with major brands. By enforcing strict manufacturing and quality control and providing customized solutions and technical support, SPARKLING MACHINERY is positioned to supply the evolving needs for modern Excavator Hydraulic Parts.

Comparing Traditional Hydraulic Systems and Emerging Architectures

The following comparison highlights differences buyers should evaluate when purchasing Excavator Hydraulic Parts for current machines versus next-generation machines.

| Feature | Traditional Hydraulic Systems | Emerging/Hybrid Systems |

|---|---|---|

| Energy Use | Constant pump flow, higher idle losses | Variable pumps, energy recovery, lower overall consumption |

| Control | Mostly mechanical/hydraulic valves | Electro-hydraulic valves and ECU integration |

| Maintenance | Reactive with periodic rebuilds | Predictive via sensors and telematics |

| Parts Complexity | Robust, simpler parts | More complex parts with electronics and sensors |

| Environmental Impact | Higher fuel use and emissions | Lower emissions, compatible with bio-fluids |

What Buyers Should Look For When Purchasing Excavator Hydraulic Parts

Procurement decisions should balance cost, compatibility, and future-readiness. Key criteria include OEM compatibility, electronic interface support, fluid compatibility, warranty and traceability, and supplier technical support. Parts offering modularity (easy sensor retrofit or ECU connections) will extend service life as machines are upgraded.

Practical Steps for Fleets and Repair Shops

Operators should start by inventorying hydraulics that would benefit from electrification or sensors—such as pumps, swing motors, and main control valves. Implementing telemetry and condition monitoring on critical hydraulic circuits delivers the fastest ROI by preventing catastrophic failures and optimizing maintenance schedules.

Risks and Challenges Ahead

Transitioning to more complex electro-hydraulic systems raises skills and training needs. Parts suppliers must invest in diagnostic tools, training materials, and cross-brand technical knowledge. Cybersecurity for connected hydraulic controls is an emerging concern as more components join machine networks.

FAQ — Frequently Asked Questions About Excavator Hydraulic Parts and the Future

Q: Will full electric excavators replace hydraulic systems soon?

A: Full electric excavators are growing in niche segments (light-duty, urban sites), but for heavy-duty applications hydraulics remain dominant due to power density. Expect a gradual shift through hybrid and electro-hydraulic systems rather than an immediate full replacement.

Q: How will electrification affect spare parts inventory?

A: Inventory will shift to include more electronic valves, sensors, ECUs, and electric pumps alongside traditional hydraulic spares. Suppliers who stock both mechanical and electronic components and provide quick diagnostic support will be most valuable.

Q: Are biodegradable hydraulic oils reliable?

A: Modern biodegradable and synthetic hydraulic fluids meet many performance requirements, but compatibility with seals and some metals must be checked. Reputable parts suppliers should validate material compatibility and provide guidance for fluid conversions.

Q: What maintenance changes should I expect with predictive maintenance?

A: Predictive maintenance reduces emergency repairs by using condition data to replace parts preemptively. This shifts purchases from “fix now” spares to planned stock and requires a supply chain that can deliver scheduled replacements reliably.

Q: How can SPARKLING MACHINERY help fleets prepare?

A: SPARKLING MACHINERY offers a broad range of hydraulic components and technical support, customization, and testing. Their quality control and global sales network make them a practical partner for fleets transitioning to more advanced hydraulic architectures.

Q: Should I buy OEM parts or high-quality aftermarket parts?

A: High-quality aftermarket Excavator Hydraulic Parts can offer cost savings and compatibility when sourced from reputable vendors with strict quality control. Ensure parts come with testing documentation, compatible warranties, and technical support.

Closing Thought

The future of excavator hydraulics is incremental and practical: greater electrification, smarter controls, improved materials, and digital maintenance practices. Suppliers and buyers who adapt—by offering sensor-ready parts, electronic controls, and reliable aftermarket support—will lead the market. SPARKLING MACHINERY’s focus on precision manufacturing, broad product range, and customer service positions it as a partner for companies preparing for this future.

Electrical Parts of Excavator: Troubleshooting Checklist 2026

The B2B Buyer’s Guide to Hydraulic Cylinders

Best excavator track chain manufacturers and supplier brands

Wholesale heavy machinery control column manufacturer and supplier

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

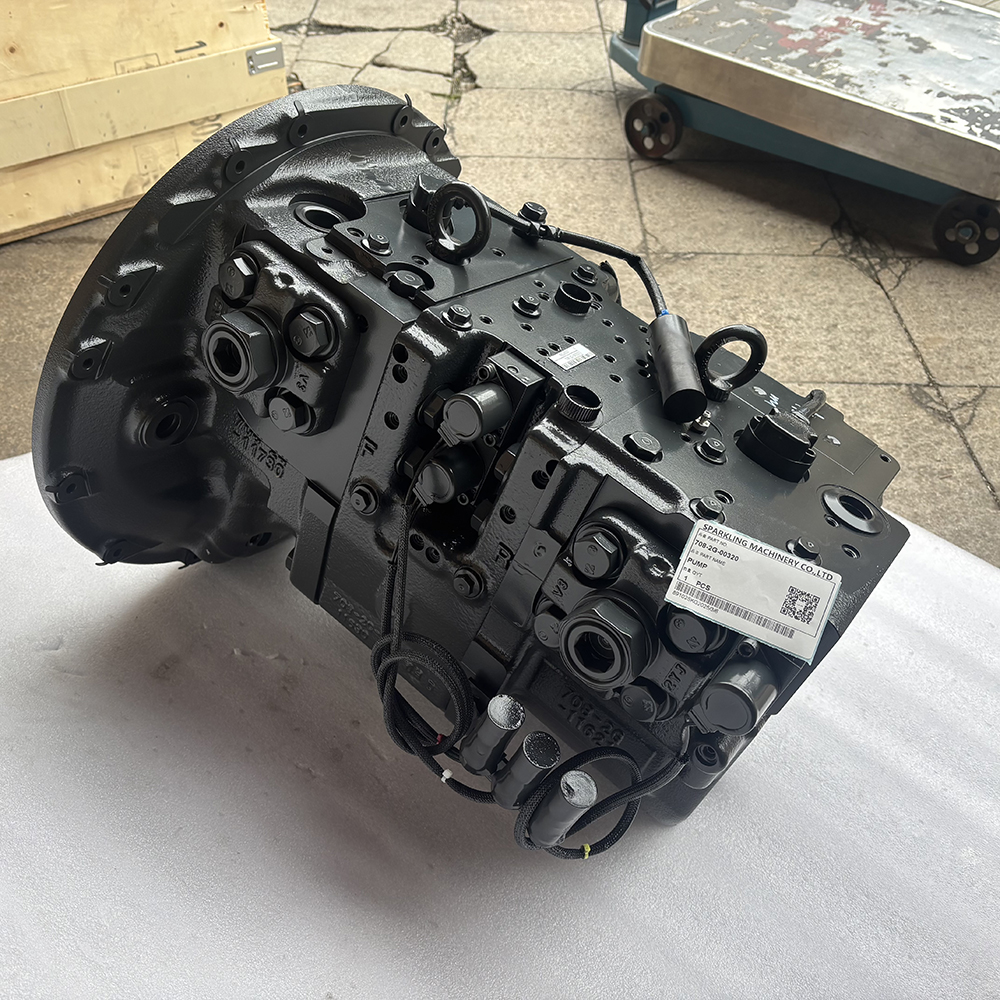

KOMATSU Made In CHINA SPARKLING MACHINERY 708-2G-00320 Pump

SPARKLING MACHINERY 708-2G-00320 Pump, a premium China-made hydraulic component, stands as a vital power transmission core for excavators. Engineered to original equipment standards, this pump ensures seamless integration with compatible excavator models, enabling direct, hassle-free installation without modifications.

Equipped with advanced hydraulic control technology, it delivers precise flow and pressure regulation in real time, optimizing operational smoothness and energy efficiency during digging, lifting, and slewing tasks. Crafted from high-strength materials, it undergoes rigorous quality testing to withstand harsh construction environments, complying with strict industry standards for long-term reliability. Backed by professional technical support and cost-effective performance, it’s the trusted choice to enhance your equipment’s productivity and reduce downtime.

Rexroth Relief Valve 04950403 R901102333 – 350 Bar Screw‑In Cartridge

The Rexroth Relief Valve 04950403 (part no. R901102333) is a precision-engineered screw-in cartridge valve designed for hydraulic systems in excavators and industrial machinery. This robust, direct-acting spool-type valve offers pressure reducing and relieving capabilities, withstanding up to 350 bar of maximum operating pressure and supporting flow rates around 30 L/min. Constructed with quality materials and standard CAAN cavity compatibility, it ensures responsive, leak-free hydraulic control under demanding conditions.

Premium XKCH-00022 solenoid valve fits Hyundai R125LCR-9A, R145CR9, R160LC9A, and R180LC9S excavators. Reliable hydraulic control part from SPARKLING

The XKCH-00022 Solenoid Valve is a precision-engineered hydraulic control component used in multiple Hyundai crawler excavators, including models R125LCR-9A, R145CR9, R160LC9A, and R180LC9S.

This solenoid valve plays a vital role in directing hydraulic fluid flow in key systems such as travel, swing, or attachment control. Engineered for responsive performance and long-lasting durability, this part ensures accurate actuation and helps maintain overall machine efficiency.

SK200-6 SK210-6 KOBELCO EXCAVATOR K3V112DT YN10V00007F1 HYDRAULIC MAIN PUMP ASSY

The K3V112DT Hydraulic Main Pump Assembly (YN10V00007F1) is a precision-engineered OEM component specifically designed for Kobelco SK200-6 and SK210-6 excavators. Manufactured to exacting standards, this pump delivers exceptional hydraulic efficiency, durability, and consistent performance under heavy-duty operating conditions. Its optimized design ensures seamless integration with your Kobelco machinery, minimizing downtime and maximizing productivity. Ideal for replacements or overhauls, this genuine assembly guarantees compatibility and reliability, backed by stringent quality control. Trust the K3V112DT to restore your excavator’s hydraulic system to peak performance.

Sparkling Machinery Co.,Ltd

foreverlucia1