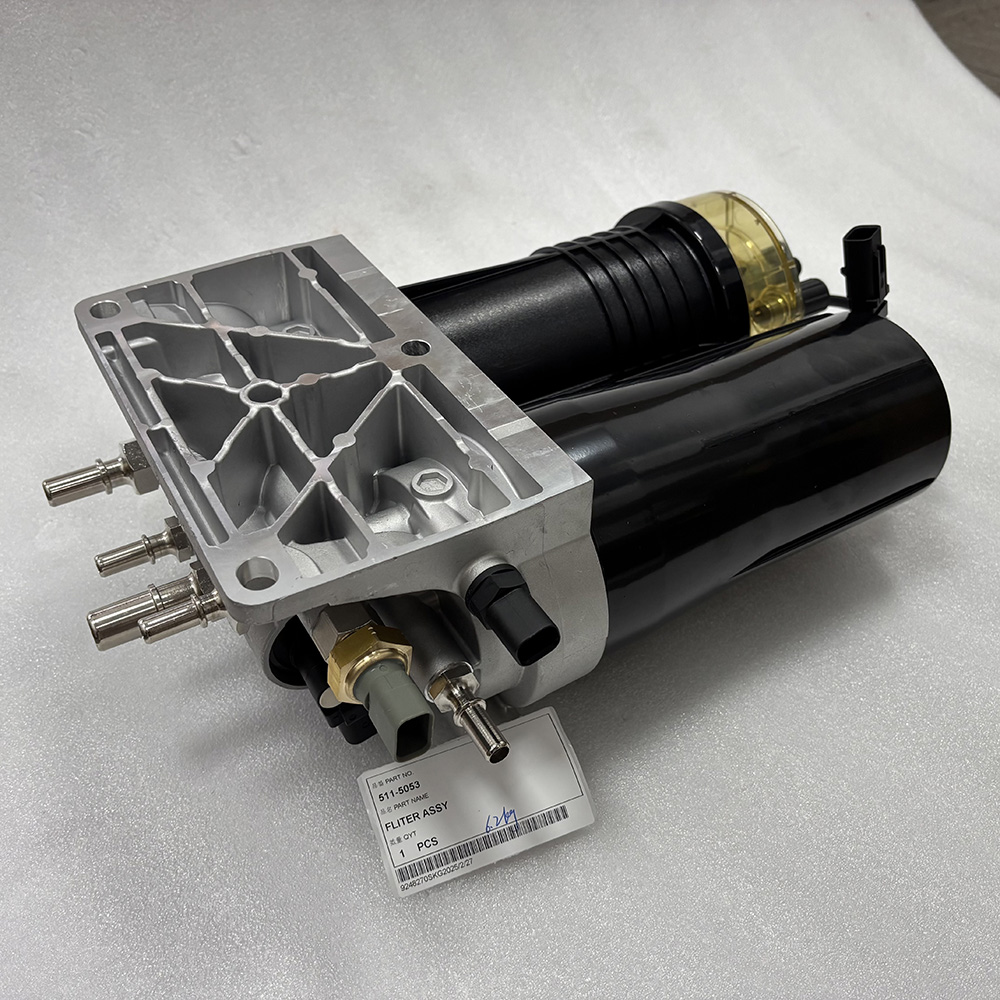

SPARKLING 511-5053 Fuel Filter – Reliable Excavator Part

The 511-5053 Fuel Water Separator Filter is designed to protect your CAT 320, 330, 320GC, and 323 series excavators from fuel contamination and moisture damage. Engineered to meet or exceed Caterpillar OEM standards, this 6.2kg high-efficiency fuel filter ensures cleaner combustion, extended engine life, and optimal fuel system performance.

With advanced multi-layer filtration media, this filter effectively separates water from diesel fuel, preventing injector wear, corrosion, and cold-start issues. Ideal for harsh job sites, this unit supports long service intervals and stable engine operation.

Manufactured and quality-checked by SPARKLING MACHINERY, this unit offers genuine-level performance at a competitive price—your smart choice for reliable excavator maintenance.

SPARKLING 511-5053 Fuel Filter: Reliable Filtration for Excavators

The SPARKLING 511-5053 fuel filter is engineered to provide optimal performance and protection for your excavator’s fuel system. Manufactured by SPARKLING MACHINERY, a trusted name in excavator parts since 2013, this fuel filter exemplifies our commitment to stability, precision, and perseverance. Designed with high-quality materials and rigorous quality control, the 511-5053 fuel filter ensures efficient removal of contaminants, safeguarding your engine components and enhancing fuel efficiency.

Compatible with leading excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, the SPARKLING 511-5053 fuel filter seamlessly integrates into your machine, providing a perfect fit and dependable operation even under demanding conditions. Our product undergoes strict manufacturing standards, guaranteeing durability and reliability to reduce maintenance costs and prevent unexpected downtime.

Beyond offering superior products, SPARKLING MACHINERY provides customized solutions and expert technical support, ensuring you receive meticulous consultation tailored to your equipment’s needs. Our global sales network and after-sales services strengthen our promise of professional and trustworthy partnerships.

Choose SPARKLING’s 511-5053 fuel filter to maintain peak excavator performance, protect your investment, and experience peace of mind backed by industry-recognized quality and innovation.

Detailed display

Q&A

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

If you have another questions, please feel free to contact us.

EXCAVATOR 320 330 320 GC 323 511-5053 5115053 FILTER GP-WATER SEPARATION 6.2KG

The 511-5053 Fuel Water Separator Filter is designed to protect your CAT 320, 330, 320GC, and 323 series excavators from fuel contamination and moisture damage. Engineered to meet or exceed Caterpillar OEM standards, this 6.2kg high-efficiency fuel filter ensures cleaner combustion, extended engine life, and optimal fuel system performance.

With advanced multi-layer filtration media, this filter effectively separates water from diesel fuel, preventing injector wear, corrosion, and cold-start issues. Ideal for harsh job sites, this unit supports long service intervals and stable engine operation.

Manufactured and quality-checked by SPARKLING MACHINERY, this unit offers genuine-level performance at a competitive price—your smart choice for reliable excavator maintenance.

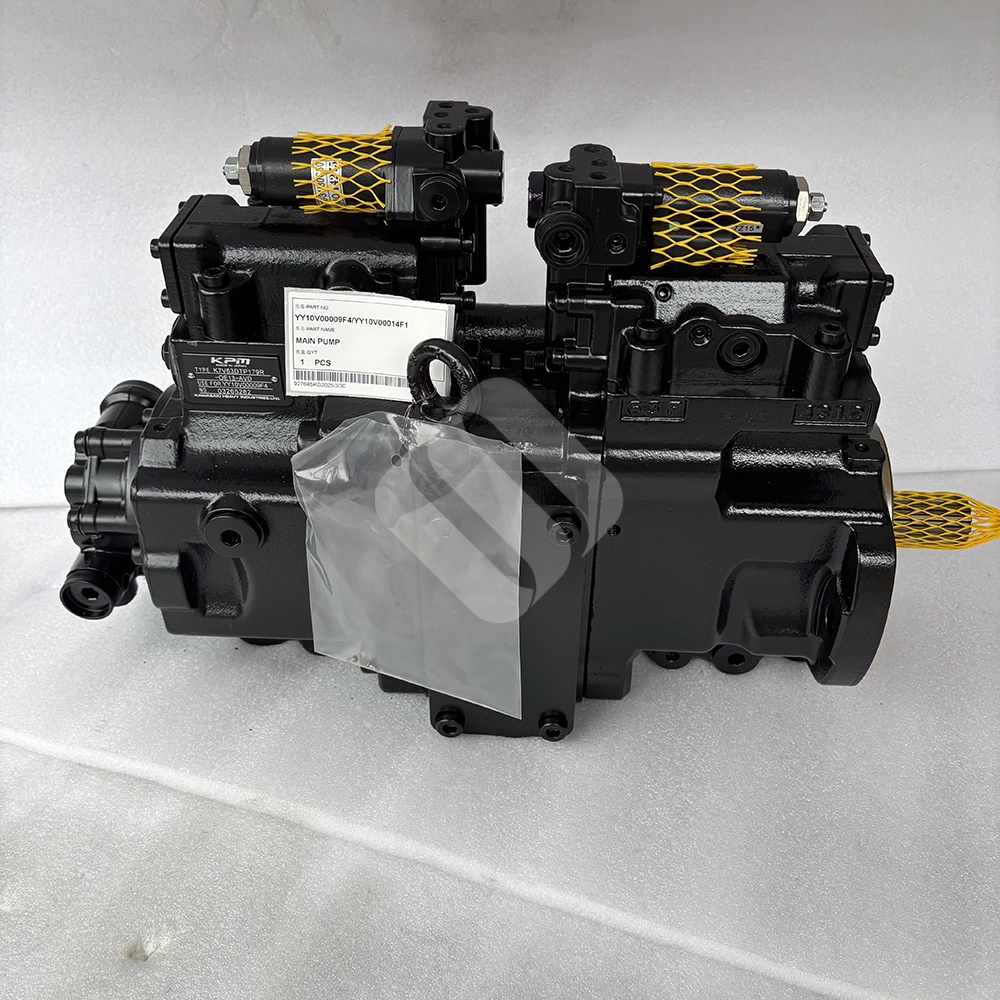

Excavator Spare Parts YY10V00009F4 YY10V00014F1 YY10V00009F1 YY10V00009F5 HYDRAULIC PUMP for Kobelco Construction Equipment Excavators SK140SRLC 140SR

The Made in China SPARKLING MACHINERY SK140SRLC/E135B Hydraulic Pump (Part Numbers: YY10V00009F4, YY10V00014F1, YY10V00009F1, YY10V00009F5) is a high-performance core component engineered for Kobelco SK140SRLC and E135B excavators. As the "heart" of the hydraulic system, it delivers consistent power transmission, ensuring smooth operation of lifting, digging, and rotating functions in heavy-duty construction scenarios. Crafted with premium materials and advanced manufacturing techniques, this pump withstands high pressure and harsh working conditions. Backed by SPARKLING’s strict quality standards, it minimizes leakage risks, reduces energy loss, and maximizes machine efficiency—your reliable choice for uninterrupted excavator performance.

Excavator Spare Parts 21Q4-32210 HCE MCU CONTROLLER for Hyundai Construction Equipment Excavators R140W-9S R170W-9S RX150LC-9

SPARKLING MACHINERY proudly presents The 21Q4-32213/32210 HCE MCU Control Unit - a premium Made in China OEM-compatible solution specifically engineered for Hyundai R140W-9S excavators. This advanced control module integrates Hydraulic Control Electronics (HCE) with a high-performance 32-bit MCU, delivering precise machine operation through CAN J1939 communication protocol. Designed for extreme conditions, it features an IP67-rated rugged enclosure and operates reliably in -30°C to +75°C environments. With real-time diagnostics and CE/ISO 13849 certification, our unit ensures your excavator maintains peak performance while reducing downtime. Offering plug-and-play replacement with 3-year warranty coverage, it's the smart choice for fleet managers seeking cost-effective, durable alternatives to OEM parts.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW BL60 BL61 EC180B L110E L120E EC210B VOE11713138 FUEL FILTER HOUSING SPARKLING MACHINERY

SPARKLING MACHINERY NEW BL60 BL61 EC180B L110E L120E EC210B VOE11713138 Fuel Filter Housing is a key fuel system component for 6 Volvo equipment models (construction/municipal use). It houses fuel filters to protect engines from impurities, ensuring clean fuel supply and stable performance.

Meeting Volvo OEM standards (VOE11713138), it resists -30°C to 85°C temps, fuel corrosion, and vibration, guaranteeing seamless compatibility and long-term reliable filtration support.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879