Buying Guide: Brake Discs for Volvo EW160C/EW180 Excavators

- Buying Guide: Brake Discs for Volvo EW160C/EW180 Excavators

- Why the right brake disc matters for Volvo EW160C/EW180 wheeled excavators

- Product highlight: VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 DISC BRAKE SPARKLING MACHINERY

- Understanding compatibility: OEM number VOE14558962 and fitment checks

- Key technical specifications to evaluate for a brake disc

- How SPARKLING MACHINERY meets Volvo OEM standards

- Performance testing and quality assurance: what to ask the supplier

- Installation best practices for brake discs on Volvo EW160/EW180

- Maintenance tips to extend brake disc life

- Troubleshooting common brake disc issues on wheeled excavators

- Comparison: OEM Volvo parts vs aftermarket vs SPARKLING MACHINERY VOE14558962

- Buying checklist: what to confirm before placing an order

- Brand strengths: Why choose SPARKLING MACHINERY for VOE14558962 discs

- Cost of ownership considerations

- Frequently Asked Questions (FAQ)

- Q: Is VOE14558962 the correct disc for all EW160 and EW180 variants?

- Q: Can I machine or resurface a worn disc instead of replacing it?

- Q: How often should I inspect the brake disc on my EW160/EW180?

- Q: Does SPARKLING MACHINERY provide warranties or test reports with VOE14558962 discs?

- Q: Are there safety risks when installing a non-OEM disc?

- Next steps and contact / view product

- Authoritative references

Buying Guide: Brake Discs for Volvo EW160C/EW180 Excavators

Why the right brake disc matters for Volvo EW160C/EW180 wheeled excavators

The brake disc is the heart of a wheeled excavator's braking system. For models such as Volvo EW160C, EW160D, EW160E, EW180C and EW180D, selecting the correct brake disc affects safety, uptime, and total cost of ownership. A properly specified disc ensures stable stopping force on roads, during loading operations, and on uneven terrain — preventing rollaways, accidents, and expensive component damage. This guide focuses on both technical and commercial aspects to help fleet managers, mechanics, and parts buyers choose the optimal solution for these Volvo wheeled excavators. After understanding the basics in the buying guide for brake discs for Volvo EW160C/EW180 excavators, many fleet managers focus on the benefits of the VOE14558962 brake disc for Volvo EW160/EW180 to evaluate value.

Product highlight: VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 DISC BRAKE SPARKLING MACHINERY

SPARKLING MACHINERY NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 Disc Brake is a dedicated safety component for VOLVO EW160C/EW160D/EW160E/EW180C/EW180D wheeled excavators (used in road construction, municipal engineering, and material handling). As the core of the braking system, it provides stable stopping force to ensure safe on-road travel and off-road operation, preventing accidents during tasks like loading or navigating uneven terrain.

Meeting VOLVO OEM standards (part no. VOE14558962), it endures high friction, -30°C to 90°C temperatures, and vibration. It resists wear and corrosion, ensuring long-term braking reliability for the five VOLVO models, with strict testing guaranteeing compatibility and safe performance.

Understanding compatibility: OEM number VOE14558962 and fitment checks

Compatibility is the first decision point. VOE14558962 is the OEM reference for the brake disc used on certain Volvo EW160 and EW180 series wheeled excavators. When buying, verify three things: the OEM part number, vehicle model/year, and any sub-variant (transmission or brake package). Purchasing a disc marketed specifically for Volvo EW160C/EW160D/EW160E/EW180C/EW180D reduces the risk of fitment issues. The SPARKLING MACHINERY product states compliance with VOE14558962, which simplifies replacement logistics and warranty traceability.

Key technical specifications to evaluate for a brake disc

Not all brake discs are equal. Important specifications include material composition, friction coefficient, thermal tolerance, thickness and runout tolerance, and surface treatment for corrosion resistance. For wheeled excavators that operate both on-road and off-road, discs must resist thermal fatigue, abrasion, and vibrational cracking.

- Material: high-grade cast iron or specially formulated grey iron with added alloying elements to improve heat conductivity and wear resistance.

- Temperature range: typical operating design for heavy equipment discs is within -30°C to +90°C (SPARKLING MACHINERY rating), covering cold starts and hot-stop conditions.

- Thickness and tolerances: match or exceed Volvo OEM spec to maintain braking geometry and pad life.

- Surface treatment: anti-corrosion coatings or protective oils for storage and transit.

How SPARKLING MACHINERY meets Volvo OEM standards

SPARKLING MACHINERY advertises their VOE14558962 disc brake as meeting Volvo OEM standards. Key manufacturer claims to validate are dimensional accuracy, material grade, heat treatment, and dynamic balancing. A good supplier will provide test certificates (material composition, hardness, runout), dimensional inspection reports, and batch traceability. For customers seeking lower-cost parts, confirm these documents and check warranty and return policies before purchase.

Performance testing and quality assurance: what to ask the supplier

Ask the supplier for specific test data: dynamic balancing, thermal fatigue tests, friction durability cycles, and salt-spray corrosion tests. Insist on batch numbers and inspection reports to ensure the product you receive meets the same standard as the sample. Reputable manufacturers also publish production standards (e.g., ISO 9001) and third-party test results. These checks reduce the risk of early wear or unsafe failure mode.

Installation best practices for brake discs on Volvo EW160/EW180

Correct installation maximizes service life and safety. Key steps include: removing rust and old mating surfaces, measuring hub runout, using a torque wrench to Volvo-specified torque values for wheel studs/bolts, and inspecting brake calipers, pads, and hardware. Replace pads and hardware if wear or damage is present; mixing a new disc with severely worn pads or seized calipers can cause uneven pad seating and reduced life. After installation, perform a controlled brake test at low speed to bed in pads and verify no vibrations or noise appear.

Maintenance tips to extend brake disc life

Regular inspections are essential. Look for scoring, thermal cracks, excessive runout, or visible corrosion pits. Maintain proper pad thickness, monitor hydraulic or air-actuated brake system pressures, and keep the disc surface free of hydraulic fluid, grease, or debris. For machines operating in corrosive or abrasive environments, increase inspection frequency and consider discs with stronger anti-corrosion coatings.

Troubleshooting common brake disc issues on wheeled excavators

Common symptoms and likely causes:

- Vibration during braking — typically warped disc (thermal stress) or excessive hub runout.

- Squealing or harsh noise — glazed pads or contaminated disc surface.

- Uneven pad wear — misaligned caliper or sticking caliper pins.

- Reduced braking efficiency — worn disc thickness below minimum or contaminated friction surface.

Address issues promptly. In many cases, replacing the disc and any damaged pads and rectifying caliper problems will restore normal performance.

Comparison: OEM Volvo parts vs aftermarket vs SPARKLING MACHINERY VOE14558962

Use this table to evaluate options. It focuses on fitment, documentation, price, and expected service life.

| Criteria | Volvo OEM Disc | Generic Aftermarket | SPARKLING MACHINERY VOE14558962 |

|---|---|---|---|

| Fitment (model-specific) | Guaranteed | Varies; risk of mismatch | Claimed direct fit for EW160C/EW160D/EW160E/EW180C/EW180D |

| Documentation & traceability | Full factory documentation | Often limited | Supplier reports and testing claimed |

| Price | Highest | Lowest | Competitive (mid-range) |

| Warranty & support | Manufacturer warranty | Limited | Commercial warranty typical; verify terms |

| Service life (typical) | Long (OEM specs) | Variable | Designed to meet OEM life expectancy |

Buying checklist: what to confirm before placing an order

Before purchase, confirm these items to reduce risk:

- Exact OEM part number (VOE14558962) and vehicle model/year match.

- Supplier provides inspection certificates (material, hardness, runout).

- Return policy and warranty details are acceptable.

- Shipping protection to prevent transit damage and correct packaging.

- Availability of replacement hardware and pads if needed.

Brand strengths: Why choose SPARKLING MACHINERY for VOE14558962 discs

SPARKLING MACHINERY emphasizes OEM specification adherence, batch testing, and compatibility with Volvo EW160/EW180 series. Their approach targets a balance of price and documented quality: manufactured to meet VOE14558962 dimensions and tested for thermal and wear performance. Buyers prioritizing traceable aftermarket parts with claimed OEM compliance often select such suppliers to reduce cost while maintaining reliability. Always validate documents and review supplier references and sample reports prior to fleet-scale purchases.

Cost of ownership considerations

Beyond purchase price, consider installation labor, downtime, required complementary parts (pads, caliper hardware), and expected replacement interval. A slightly higher-priced disc that lasts longer or avoids unscheduled downtime often offers lower total cost of ownership. Maintain a spare disc in inventory for rapid replacement to reduce machine off-time on critical jobs.

Frequently Asked Questions (FAQ)

Q: Is VOE14558962 the correct disc for all EW160 and EW180 variants?

A: VOE14558962 is specified for certain EW160C/D/E and EW180C/D wheeled excavator configurations. Always verify fitment using the machine serial number or consult the Volvo parts manual before ordering.

Q: Can I machine or resurface a worn disc instead of replacing it?

A: Resurfacing may be possible if the disc thickness remains above the minimum specification and there are no thermal cracks. However, many manufacturers recommend replacement for heavy equipment discs when wear or damage is evident to maintain reliable braking.

Q: How often should I inspect the brake disc on my EW160/EW180?

A: Inspect discs during scheduled maintenance intervals and more frequently if the machine operates in abrasive, corrosive, or heavy-stop conditions. Check for scoring, cracking, runout, and thickness loss.

Q: Does SPARKLING MACHINERY provide warranties or test reports with VOE14558962 discs?

A: Reputable suppliers typically provide warranty and batch test documentation. Before purchase, request written confirmation of these documents and verify the scope and duration of the warranty.

Q: Are there safety risks when installing a non-OEM disc?

A: Non-OEM discs that do not meet Volvo's dimensional or material specifications can create uneven braking, excessive wear, or premature failure — posing safety risks. If using aftermarket parts, ensure they include documentation proving compliance with OEM tolerances and performance.

Next steps and contact / view product

If you need the VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 DISC BRAKE SPARKLING MACHINERY or wish to discuss fleet-level procurement, contact our sales team for certificates, lead times, and pricing. We can provide test reports, packaging photos, and references to support your procurement decision. Contact: sales@example.com or click View Product / Request Quote.

Authoritative references

- Brake disc background and function — Wikipedia: Brake disc: https://en.wikipedia.org/wiki/Brake_disc

- Volvo Construction Equipment — Support & parts information: https://www.volvoce.com/global/en/support/

- Brake system basics and maintenance — How a Car Works: Brake discs and disc brakes: https://www.howacarworks.com/works/brake-discs-and-discs-brakes

- General guidance on heavy equipment maintenance — Volvo CE Service & Maintenance pages: https://www.volvoce.com/global/en/support/service-and-maintenance/

Note: Always follow Volvo's service manual and safety guidelines for your specific machine serial number. When in doubt, consult a certified Volvo technician.

Ordering Guide: Lead Times for K9003219 Pulley Parts

Best excavator track chain manufacturers and supplier brands

How to Verify Compatibility: LC52S00019P1 Low Pressure Sensor

How to Evaluate Suppliers for Volvo EC480D Hydraulic Hose

faq

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

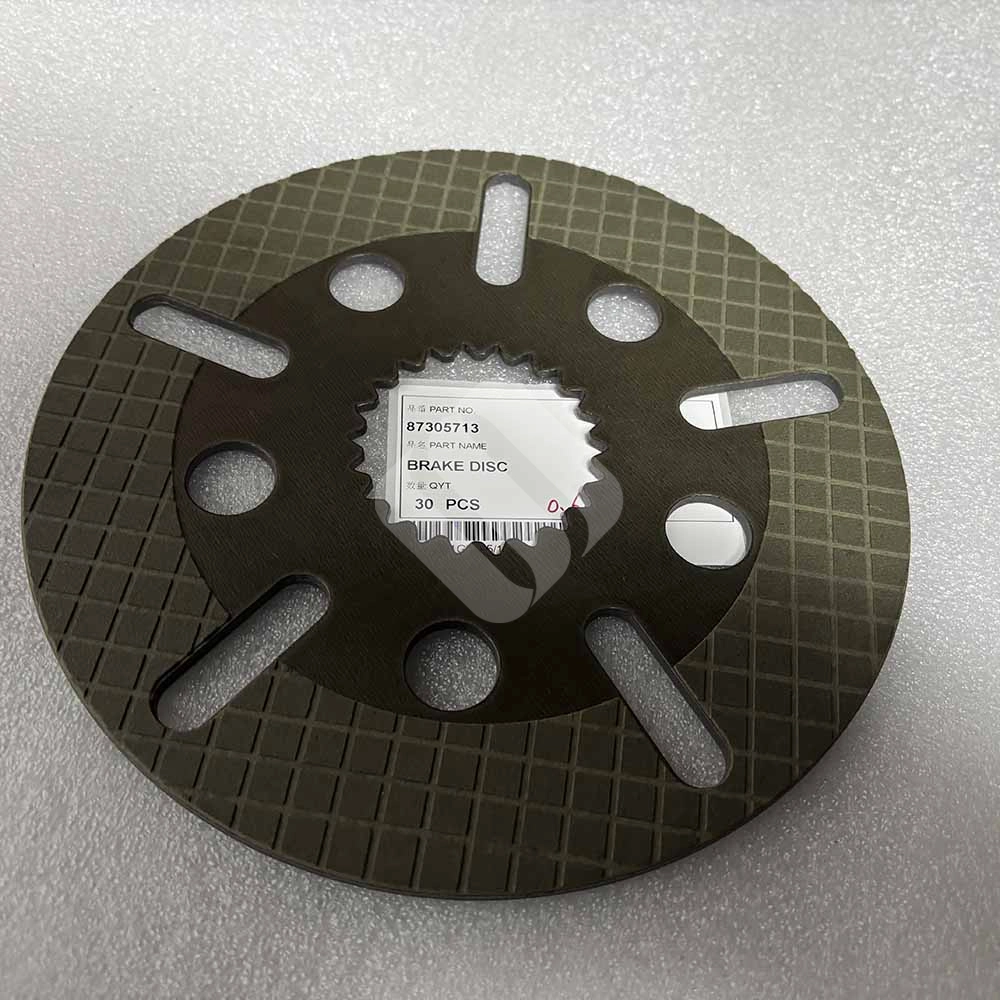

VOLVO HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B110B B100B LB90.B B90B B95B 87305713 BRAKE DISC SPARKLING MACHINERY

SPARKLING MACHINERY NEW B110B B100B LB90.B B90B B95B 87305713 Brake Disc is a core braking component for Volvo B110B/B100B/LB90.B/B90B/B95B excavators (heavy-duty construction/mining use). It works with brake pads to generate friction, ensuring reliable stopping and operational safety.

Meeting Volvo OEM standards (87305713), it resists -30°C to 300°C temps, wear, and thermal deformation, ensuring seamless compatibility and long-term reliable braking performance.

New Holland Backhoe Loaders 87305713 83959970 47123297 Brake Disc

87305713 is a specific industrial part number for a Brake Disc (or Friction Plate) used in agricultural and construction machinery, primarily manufactured by New Holland.

1.This friction disc is designed for oil-immersed (wet) braking systems. It is commonly found in:

New Holland Backhoe Loaders: Models including B90B, B100B, B110B, B115B, LB75, LB90, LB110, and LB115.

Ford Tractors: Series 550, 555, and 655.

Case IH: Certain models sharing the same drivetrain components

2. Technical Specifications

Outside Diameter (OD): ~204.75 mm

Inside Diameter (ID): ~55.88 mm (spline area)

Thickness: 4.8 mm

Teeth Count: 22 Teeth

Material: Paper-based friction material with a waffle-groove pattern for oil circulation and cooling

3. Cross-Reference Numbers

This part is often interchangeable with the following OEM and aftermarket numbers:

CNH: 83959970, 47123297

Ford/NH Original: E6NN2A097BB

Hyundai Wheel Loaders HL730-9 HL730-9A HL730-9S ZGAQ-03450 0501.323.355 DISC-INNER CLUTCH CHINA MADE

Part numbers 0501.323.355 (a ZF part number) and ZGAQ-03450 (a Hyundai part number) both refer to a Friction Disc used in the brake or clutch assembly of heavy machinery transmissions and axles.

This component is an inner clutch or brake friction plate/disc. It is a critical wear item within the drivetrain assembly (likely a ZF axle or transmission) responsible for creating the necessary friction to engage clutches or apply brakes in heavy equipment.

Compatible Equipment

This friction disc is commonly used in Hyundai wheel loaders and other construction equipment that utilize compatible ZF axles:

Hyundai Wheel Loaders: HL730-9, HL730-9A, HL730-9S, HL730TM-9A.

Other Compatible Equipment: Various backhoe loaders, including certain models by John Deere (e.g., 310, 315, 210K, 310SJ, 325K)

Part Numbers: 0501.323.355, 0501323355, ZGAQ-03450, ZGAQ03450, AT339543, 482-6743, VOE 15071853, S06/42932

ZTAM-00615 Support Kit Compatible with Hyundai R140W-7 & R140W-7A Wheel Excavators

ZTAM-00615 is an OEM-compatible support kit for Hyundai R140W-7/R140W-7A excavators. It provides essential structural reinforcement and vibration damping for key components, ensuring reliable performance under heavy loads and harsh working conditions in construction and engineering applications.

Key Features

· OEM direct‑fit design: Exact matching of mounting positions, hole spacing, and geometric dimensions for Hyundai R140W‑7 / R140W‑7A — plug‑and‑play without modification.

· High‑strength structural support: Heavy‑duty steel construction with reinforced stress points for excellent load capacity and impact resistance.

· Stable & durable: Anti‑wear, anti‑deformation, and anti‑corrosion surface treatment for long service life in harsh environments.

Compatible Models: Hyundai Wheel Excavators R140W-7, R140W-7A

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879