How to Verify Compatibility: LC52S00019P1 Low Pressure Sensor

- How to Verify Compatibility: LC52S00019P1 Low Pressure Sensor

- Introduction to the LC52S00019P1 low pressure sensor and

- Why verifying compatibility of a low pressure sensor matters

- Quick compatibility checklist (overview)

- Physical identification: how to read part markings and ensure fitment

- Electrical compatibility: connectors, wiring, and switch logic

- Hydraulic and pressure specifications: understanding the 3MPa rating

- Compatibility table: part number comparisons and basic specs

- Step-by-step verification procedure before purchase

- On-machine diagnostic tests to confirm functional compatibility

- Common installation pitfalls and best practices

- Troubleshooting guide for symptoms after replacement

- Brand considerations and why SPARKLING/aftermarket equivalents can be acceptable

- Summary: practical purchasing and verification workflow for fleet managers

- FAQ

- Contact and view product

- References and authoritative resources

How to Verify Compatibility: LC52S00019P1 Low Pressure Sensor

Introduction to the LC52S00019P1 low pressure sensor and

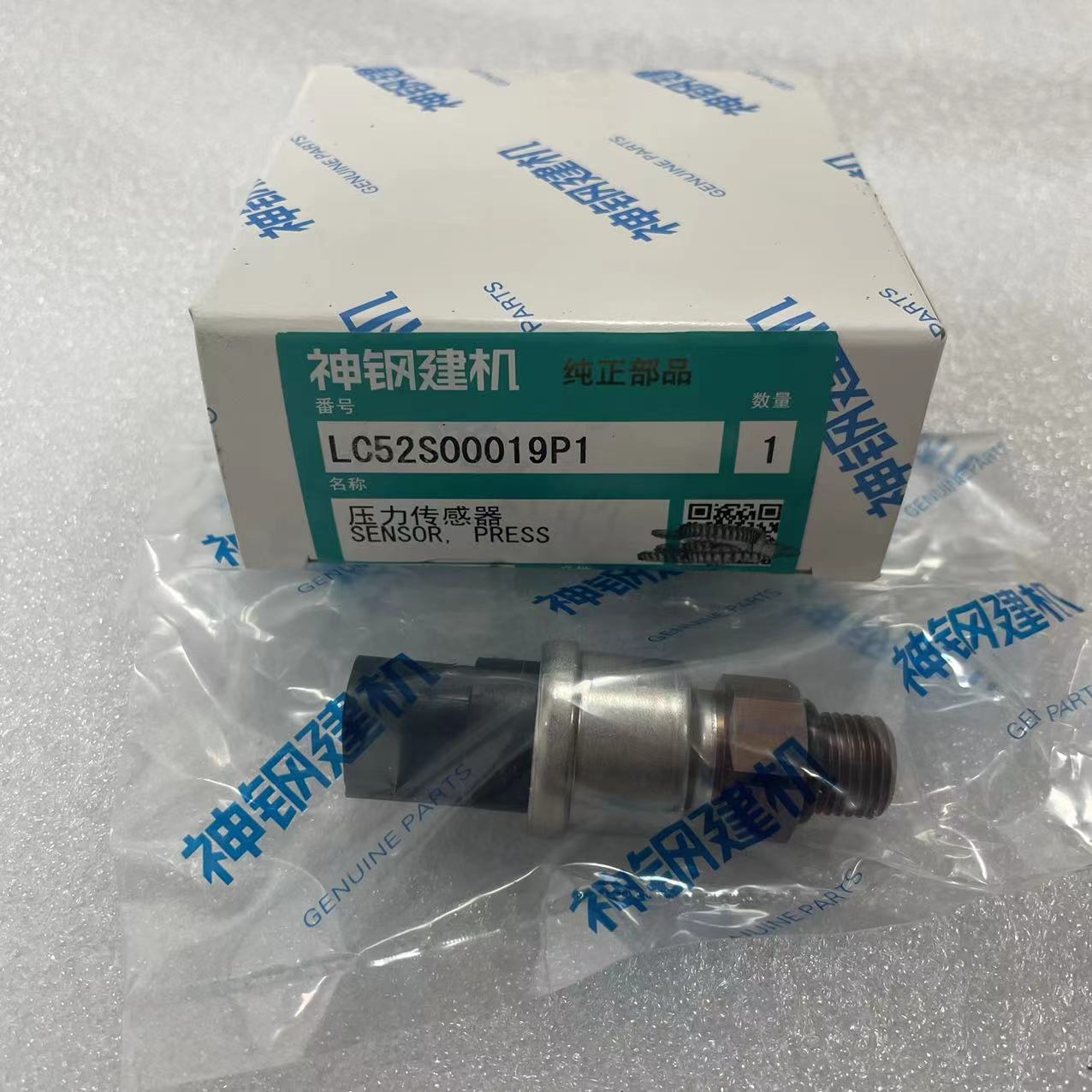

The SPARKLING SK200-6/6E/8, SK250-6E/8, SK460-8, SK480-8 Low Pressure Sensor (3Mpa) models LC52S00019P1, YN52S00102P1, YW52S00002P1, LS52S00013F1 ensure precise switch control. Designed for reliable low pressure sensing, these sensors optimize performance and durability in industrial applications. Part number LC52S00019P1 refers to an electronic hydraulic low-pressure sensor used primarily in heavy machinery such as excavators. It is designed to monitor hydraulic pressure conditions to ensure system safety, triggering alerts or shutdowns if pressure falls below safe thresholds. If you need to buy or replace a low pressure sensor, verifying compatibility before purchase or installation avoids costly downtime and equipment damage.

Why verifying compatibility of a low pressure sensor matters

Not all pressure sensors are interchangeable. Even where multiple part numbers appear similar, differences in pressure range, thread size, electrical connector or internal switch logic can make one sensor incompatible with another machine. Using an incorrect sensor can cause false alarms, failure to protect hydraulic systems, or electrical damage to the machine control unit. When your is to buy, replace, or stock LC52S00019P1 type sensors, following a verification checklist ensures the part will function correctly in Kobelco and supported New Holland models and reduces return rates.

Quick compatibility checklist (overview)

Use this checklist before ordering or installing a low pressure sensor: confirm exact part number (LC52S00019P1, YN52S00102P1, YW52S00002P1, LS52S00013F1), verify pressure range (3MPa), confirm mechanical thread and mounting, check electrical connector and pinout, compare switch type and hysteresis, test continuity and response, and review OEM compatibility with model lists such as Kobelco SK series and New Holland excavators.

Physical identification: how to read part markings and ensure fitment

Start by inspecting the sensor body for stamped or printed part numbers. LC52S00019P1 is typically visible on the hex body or plastic housing; cross-reference with alternative numbers YN52S00102P1, YW52S00002P1, LS52S00013F1. Confirm the thread type (commonly metric) and thread size visually or by measuring with a caliper and thread gauge. Measure thread diameter and pitch; common hydraulic sensor threads are M16x1.5 or 1/4-18 NPT on some machines, but do not assume—measure to confirm. Also verify the hex size for the mounting wrench and the overall sensor length so it will physically clear surrounding fittings and harnesses on the excavator model (SK200-6, SK250-6E/8, SK460-8, SK480-8, etc.).

Electrical compatibility: connectors, wiring, and switch logic

Electrical mismatches are the most common cause of incompatibility. Check the connector type (two-pin, three-pin, or specific OEM harness). Confirm pin assignments and wire colors where possible. Verify whether the sensor outputs a simple switch contact (normally open or normally closed) or provides an electronic signal (analog or digital). For the LC52S00019P1 low pressure sensor used in Kobelco models, most are simple switch-type sensors that change state when pressure falls below a preset threshold (3MPa rating). When replacing, match the switch type and logic (NO vs NC) to the original. If the replacement has the opposite logic, install only after modifying the control logic or using an adapter relay; otherwise alarms or shutdowns will behave oppositely.

Hydraulic and pressure specifications: understanding the 3MPa rating

The 3MPa (megapascal) rating means the sensor is calibrated to operate around a 3MPa threshold. Confirm the machine's system control and safety setpoints use a similar threshold. If the machine normally operates near or below 3MPa, a sensor with a different trip point will not protect the system correctly. Also check maximum burst pressure and temperature ratings. Sensors should be rated for the hydraulic fluid temperature and operating environment of the excavator. Using a sensor with inadequate temperature or pressure tolerance risks premature failure.

Compatibility table: part number comparisons and basic specs

Use the table below to compare primary part numbers and key parameters at a glance.

| Part Number | Typical Use | Pressure Range/Trip | Connector | Compatible Models (examples) |

|---|---|---|---|---|

| LC52S00019P1 | Electronic hydraulic low-pressure switch | 3MPa trip (nominal) | OEM 2/3-pin connector (varies) | Kobelco SK130-8 to SK480-8, selected New Holland models |

| YN52S00102P1 | Alternate part number / equivalent | 3MPa | OEM compatible | Same Kobelco SK series |

| YW52S00002P1 | Alternate / compatible supplier | 3MPa | Varies—confirm pinout | Kobelco & select New Holland |

| LS52S00013F1 | OEM-equivalent | 3MPa | OEM | Kobelco SK series |

Step-by-step verification procedure before purchase

1) Gather original part number and take photos of the installed sensor and harness. 2) Measure thread size and pitch with a gauge and record connector type. 3) Confirm the pressure setpoint required by the machine manual or control system (3MPa for these parts). 4) Check OEM parts catalog or parts label against LC52S00019P1 and equivalents. 5) If buying aftermarket, request datasheets and wiring diagrams from the supplier. 6) If any parameter differs (trip point, connector, thread), do not install without verifying an adapter or ECU reprogramming option.

On-machine diagnostic tests to confirm functional compatibility

Before final installation, perform bench and on-machine tests: use a calibrated hydraulic pressure source to apply pressure and observe switch behavior around 3MPa. With the connector disconnected, use a multimeter to check continuity between the sensor pins as pressure varies. Confirm the contact opens/closes at expected pressure and that hysteresis (difference between trip and reset pressure) matches OEM spec. After installation, monitor the machine's alarms and control responses under controlled conditions to ensure the sensor triggers the expected safety actions.

Common installation pitfalls and best practices

Do not overtighten the sensor—use the correct torque value from the OEM or sensor datasheet. Apply thread sealant only where specified; some sensors require PTFE or specific hydraulic sealing compounds. Keep wiring away from high-temperature components and rotating parts; secure with proper clips. Replace corroded connectors and use dielectric grease where recommended to prevent false readings due to poor electrical contact. When in doubt, consult the machine's service manual or a certified technician to avoid warranty issues.

Troubleshooting guide for symptoms after replacement

Symptom: persistent alarm although pressure is normal — check switch logic (NO/NC) and wiring polarity. Symptom: no alarm when pressure drops — verify sensor trip point, test continuity under pressure, check fused power to the control circuit. Symptom: intermittent readings — inspect connectors for corrosion or broken wires and verify grounding. If the new sensor is mechanically leaking, check thread seal and mounting torque; replace if damaged.

Brand considerations and why SPARKLING/aftermarket equivalents can be acceptable

OEM sensors like those listed for Kobelco (LC52S00019P1 and equivalents) are designed to meet stringent specifications. Reputable aftermarket brands such as SPARKLING that explicitly list compatibility with SK200-6/6E/8, SK250-6E/8, SK460-8, and SK480-8 will often meet or exceed OEM durability if they provide proper specifications, warranty and test data. When choosing a supplier, request datasheets, sample testing data, and references from other fleets. Good vendors will provide cross-reference tables, clear return policies, and technical support for installation and calibration.

Summary: practical purchasing and verification workflow for fleet managers

1) Confirm original part and working requirements (3MPa trip, connector type, thread). 2) Ask supplier for datasheet and pinout. 3) Measure and compare physical dimensions. 4) Bench-test sensor with a pressure source and multimeter. 5) Install and verify machine behavior under safe conditions. 6) Keep a spares policy: stock the correct part numbers (LC52S00019P1, YN52S00102P1, YW52S00002P1, LS52S00013F1) and one compatible alternative to reduce downtime. Following these steps will ensure you buy the correct low pressure sensor and avoid installation failures or false alarms.

FAQ

Q: Is LC52S00019P1 compatible with all Kobelco SK series models?

A: LC52S00019P1 is compatible with many Kobelco SK series models listed in the product application notes, including SK130-8, SK140LC-8, SK200-6/6E/8, SK210-6E/8/9, SK230-6E, SK250-6E/8, SK260-8/9, SK330-6E/8, SK350-8/9, SK460-8, and SK480-8. Always verify specific machine serial number compatibility through the OEM parts catalog.

Q: Can I use a sensor with a different trip pressure?

A: No — if the trip pressure differs from the machine's required setpoint (3MPa in this family), the sensor will not provide correct protection. Use only those rated for required thresholds or adjust the control logic with expert assistance.

Q: How do I know if my sensor is NO or NC?

A: Bench-test with a multimeter while applying pressure. Record whether continuity appears (closed) at rest and whether it opens at pressure, indicating NO or NC behavior. Cross-check with OEM documentation.

Q: What if the connector on the new sensor doesn't match?

A: Do not force mismatched connectors. Use OEM harness adapters or have a qualified technician re-pin the connector if a verified wiring diagram supports the change. Incorrect wiring can damage ECU circuits.

Q: Where can I buy verified replacements?

A: Purchase from authorized parts distributors, the machine OEM dealership, or trusted aftermarket suppliers that provide datasheets, warranty, and return policies. Ask for cross-reference confirmation for LC52S00019P1 and equivalent numbers.

Contact and view product

If you need the LC52S00019P1 3MPa low pressure sensor or assistance verifying compatibility for a specific machine, contact our sales and technical team for parts identification, datasheets, and on-site support. Click to view product details, request a quote, or arrange a bench test with one of our technicians. Our team can provide wiring diagrams, torque specs, and compatibility checks for Kobelco and New Holland models.

References and authoritative resources

For technical background and independent standards consult these authoritative sources:

- Pressure sensor general overview - Wikipedia: https://en.wikipedia.org/wiki/Pressure_sensor

- Kobelco Construction Machinery - official site (parts and service): https://www.kobelco-kenki.co.jp/en/ (refer to regional dealer pages for parts catalogs)

- New Holland Construction - official site (model information and parts): https://construction.newholland.com/

- Hydraulic system basics and safety guidance - National Fluid Power Association: https://www.nfpa.com/ (industry resource for hydraulics)

These resources provide general technical context; always use the OEM parts catalog and machine service manual for final verification on a specific serial-numbered unit.

Hydraulic Cylinder Maintenance: Ensuring Smooth Excavator Operations

Inspection Checklist for Volvo Excavator Disc Brakes

Compatibility Guide: Bearings for R210W-9 and R200W7A

Buying Guide: Genuine vs OEM Parts of Excavator 2026

faq

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

SK200-6/6E/8 SK250-6E/8 SK460-8 SK480-8 LC52S00019P1 YN52S00102P1 YW52S00002P1 LS52S00013F1 3Mpa Low Pressure Sensor

The SPARKLING SK200-6/6E/8, SK250-6E/8, SK460-8, SK480-8 Low Pressure Sensor (3Mpa) models LC52S00019P1, YN52S00102P1, YW52S00002P1, LS52S00013F1 ensure precise switch control. Designed for reliable low pressure sensing, these sensors optimize performance and durability in industrial applications.

Part number LC52S00019P1 refers to an electronic hydraulic low-pressure sensor used primarily in heavy machinery such as excavators. It is designed to monitor hydraulic pressure conditions to ensure system safety, triggering alerts or shutdowns if pressure falls below safe thresholds.

Applications

The sensor is compatible with a wide range of Kobelco and some New Holland excavators, including:

Kobelco SK Series: SK130-8, SK140LC-8, SK200-6/6E/8, SK210-6E/8/9, SK230-6E, SK250-6E/8, SK260-8/9, SK330-6E/8, SK350-8/9, SK460-8, and SK480-8.

New Holland Models: E70, E135, E175, E215, and E235.

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879