Choosing the Right Taper Roller Bearing for R200W7 Models

- Why Taper Roller Bearings Matter for R200W7 Machines

- Role inside the excavator's rotating systems

- How bearing choice affects key parts of an excavator

- Standards and lifecycle expectations

- Selecting the Correct ZGAQ-02328 Bearing for R200W7 Models

- Confirming fit and compatibility

- Load rating, material and heat treatment

- Comparing OEM vs aftermarket options

- Installation, Maintenance and Troubleshooting for R200W7 Bearings

- Proper installation steps

- Lubrication and monitoring

- Common failure modes and corrective actions

- Sourcing, Cost and Lifecycle Decisions

- Where to buy and verifying authenticity

- Cost vs lifecycle trade-offs

- When to upgrade or retrofit

- References and Further Reading

- FAQ — Choosing and Using ZGAQ-02328 on R200W7 Models

- Q: Is ZGAQ-02328 a direct OEM replacement for R200W7 swing shaft bearings?

- Q: How often should I inspect the taper roller bearing on an R200W7?

- Q: Can I reuse the old cone/cup when replacing the bearing?

- Q: What are the signs that the bearing is failing?

- Q: Who should I contact for purchasing or technical support?

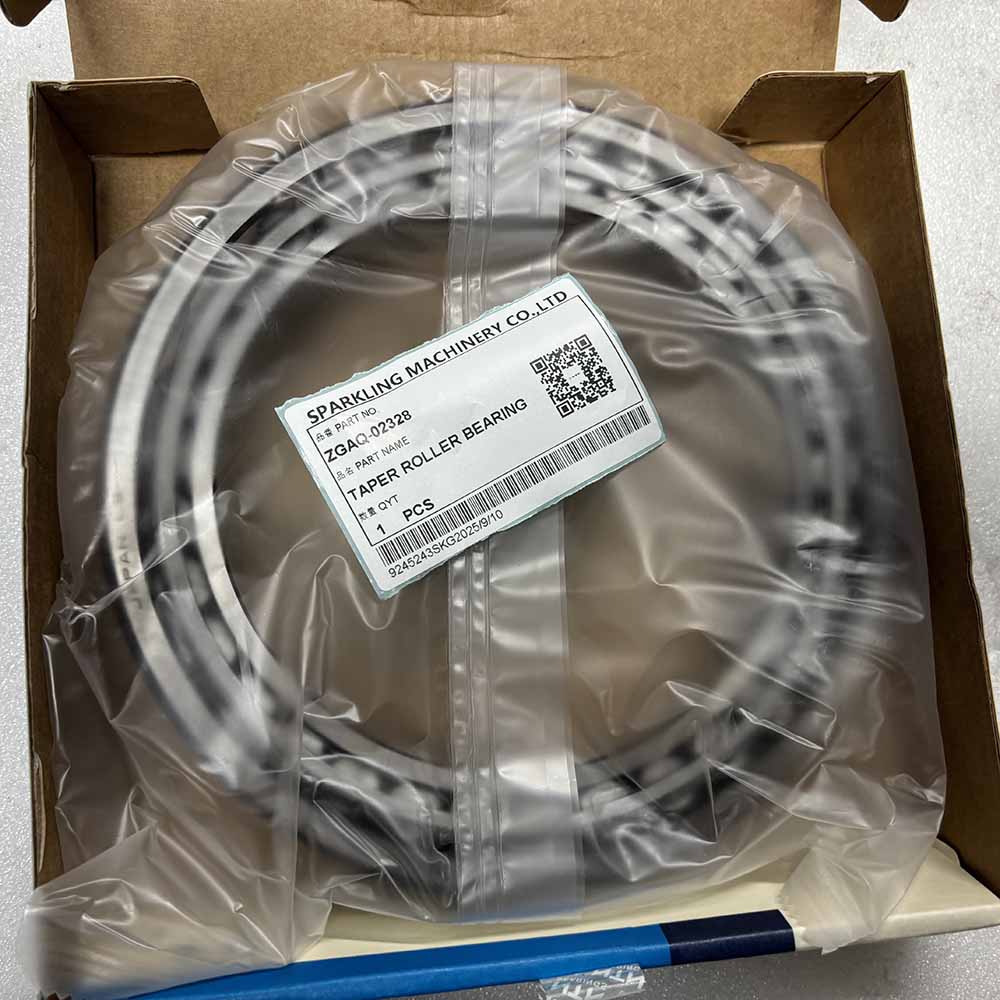

This guide helps owners, maintenance teams and parts managers choose the correct taper roller bearing for HYUNDAI R200W7 family excavators (including R200W7A, R210W-9 and HW210 models). It explains how the SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing meets Hyundai OEM requirements, how it functions inside key systems (swing, final drive and shaft assemblies), and what to check for during selection, installation and routine inspection to maximize service life and minimize downtime.

SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing is a core rotating component for Hyundai excavators (construction/mining use). It withstands combined radial and axial loads, ensuring smooth rotation of key shaft parts.

Meeting Hyundai OEM standards (Part No.: ZGAQ-02328), it delivers high wear resistance and load capacity, guaranteeing seamless compatibility and long-term stable operational performance.

Why Taper Roller Bearings Matter for R200W7 Machines

Role inside the excavator's rotating systems

Tapered roller bearings are used where combined radial and axial loads occur. In R200W7-type machines they commonly support components such as the swing gearbox input shaft, boom pivot shafts, travel axle assemblies and axle-mounted pinion gears. Unlike simple ball bearings, a properly selected taper roller bearing handles thrust from the bucket and boom during digging, plus radial loads from travel and swing functions.

How bearing choice affects key parts of an excavator

An incorrect bearing affects the performance of many parts of an excavator: increased play at the swing bearing causes uneven swing motion; worn taper bearings at pivot shafts accelerate wear of pins and bushings; improper bearings in final drives can lead to gearbox overheating and seal failure. Choosing a bearing that meets OEM dimensional, load and material specifications reduces stress on seals, shafts and housings and preserves hydraulic efficiency.

Standards and lifecycle expectations

Design life and load ratings for tapered roller bearings are governed by international practice; for rolling bearings refer to tapered roller bearing basics and the ISO life calculation standards such as ISO 281. OEM‑grade parts like ZGAQ-02328 are manufactured to meet Hyundai tolerances and hardness profiles so they can reach expected service intervals under normal operating conditions.

Selecting the Correct ZGAQ-02328 Bearing for R200W7 Models

Confirming fit and compatibility

Start by verifying the machine model and component location (swing gearbox vs axle vs pivot). HYUNDAI part number ZGAQ-02328 is specified for certain rotating shafts on R200W7, R200W7A and R210W-9 series. Always cross-check the part number against the parts manual or exploded diagrams for the relevant assembly to avoid mismatched inner/outer ring dimensions or cone/cup pairings. Confirm bore and width, cone angle and cup seating dimensions match the housing and shaft tolerances.

Load rating, material and heat treatment

Key selection parameters are dynamic load rating (C), static load rating (C0), material quality (through-hardened bearing steel vs surface-hardened), and heat treatment consistency. SPARKLING MACHINERY's ZGAQ-02328 is produced to Hyundai OEM hardness and through‑hardened steel specifications, improving wear resistance under repetitive digging loads. For heavy duty applications (quarry or demolition), consider a bearing with higher static load rating or increased cage strength.

Comparing OEM vs aftermarket options

When choosing between OEM ZGAQ-02328 and generic aftermarket bearings, consider warranty coverage, material traceability and dimensional tolerances. Below is a comparison table that highlights typical differences relevant to R200W7 use cases.

| Feature | ZGAQ-02328 (SPARKLING MACHINERY, OEM spec) | High Quality Brand Equivalent | Generic Aftermarket |

|---|---|---|---|

| Dimensional Tolerance | OEM tolerance per Hyundai specification | Tight tolerance, certified | Variable; may require fitting |

| Material & Heat Treatment | Through‑hardened bearing steel, controlled process | High-grade steel, advanced heat treatment | Unknown alloy/HT in many cases |

| Load Ratings | Matched to Hyundai load specs | Equal or higher than OEM | Often lower than OEM ratings |

| Traceability & Warranty | Full traceability, warranty support | Manufacturer traceability, warranty | Limited traceability, minimal warranty |

Reference: general bearing concepts summarized at Tapered Roller Bearing - Wikipedia.

Installation, Maintenance and Troubleshooting for R200W7 Bearings

Proper installation steps

Correct installation is critical. Typical steps include cleaning shaft and housing surfaces, checking shaft runout and housing alignment, fitting cone and cup at correct interference or clearance, and applying recommended grease. Use calibrated press tools—not hammer blows—when seating cones and cups. After installation, rotate the assembly by hand to verify smooth motion and correct preload. For detailed instructions, follow Hyundai's service manual for the specific assembly to which the ZGAQ-02328 is fitted.

Lubrication and monitoring

Use the grease grade specified in the machine manual—incorrect grease affects rolling element film and increases wear. Monitor temperature, noise and vibration: rising temperature or unusual chatter are early signs of bearing distress. Regular inspection of seals and adjacent parts (pins, bushings, seals and the housing) will prevent contamination and premature failure.

Common failure modes and corrective actions

Common failure modes include brinelling from shock loads, false brinelling from vibration during storage, material fatigue from overloading, ingress of contaminants causing abrasive wear, and improper preload leading to early wear. Corrective actions: recheck fit and preload, replace damaged seals, improve filtration, use correct grease, and if necessary upgrade to a higher-rated bearing or protective sealing solution.

Sourcing, Cost and Lifecycle Decisions

Where to buy and verifying authenticity

Buy from authorized dealers or reputable parts suppliers who can provide a certificate of conformity and traceability. Counterfeit or substandard bearings can be dimensionally similar but lack proper steel or heat treatment, reducing life dramatically. If in doubt, request material certificates and batch heat-treatment records from the supplier.

Cost vs lifecycle trade-offs

Upfront cost savings on cheap bearings often lead to higher lifecycle costs due to more frequent replacements, downtime and collateral damage to shafts and housings. OEM-grade ZGAQ-02328 is designed to match Hyundai tolerances to minimize these risks. Budget for proper installation and maintenance—those are often cheaper than replacing bearings mid-project.

When to upgrade or retrofit

Consider an upgrade if operating conditions exceed original design assumptions: frequent heavy shock loading, abrasive environments (sand/gravel), or continuous high-temperature operation. Upgrades may include bearings with higher static/dynamic ratings, improved cage materials, or added sealing solutions. Always validate fit and consult engineering guidance before retrofitting major assemblies.

References and Further Reading

- Tapered roller bearing - Wikipedia

- Excavator - Wikipedia

- ISO 281 - Rolling bearings — Dynamic load ratings

FAQ — Choosing and Using ZGAQ-02328 on R200W7 Models

Q: Is ZGAQ-02328 a direct OEM replacement for R200W7 swing shaft bearings?

A: Yes. SPARKLING MACHINERY NEW ZGAQ-02328 is manufactured to Hyundai OEM specifications and is intended as a direct replacement for the specified bearing positions in the R200W7/R210W-9 series. Always verify the part number on the parts diagram for your serial number.

Q: How often should I inspect the taper roller bearing on an R200W7?

A: Perform a visual and functional inspection every 250 operating hours or during scheduled major services. Check for noise, temperature rise, lubricant condition and seal integrity. High-duty or severe environment machines may require more frequent inspections.

Q: Can I reuse the old cone/cup when replacing the bearing?

A: Reuse is not recommended unless the old cone and cup pass dimensional and surface finish checks as per the service manual. Reusing damaged or worn components risks premature failure of the new bearing.

Q: What are the signs that the bearing is failing?

A: Early signs include unusual vibration, increased operational temperature, metal particles in grease, and increased axial or radial play. If detected, stop operation and inspect immediately to prevent secondary damage to shafts, seals, and gear teeth.

Q: Who should I contact for purchasing or technical support?

A: For product inquiries, pricing, or technical support related to SPARKLING MACHINERY NEW ZGAQ-02328, contact our parts team or local distributor. We provide fitment checks, material certificates, and installation guidance to ensure proper compatibility with R200W7 family machines.

Contact Sales / View Product: Contact our parts team or view the ZGAQ-02328 product page for availability, pricing and OEM cross-reference assistance.

This article follows general industry references for rolling bearings and excavator components and is intended to help technicians and fleet managers make informed decisions about parts selection and maintenance. For machine‑specific procedures always consult the official Hyundai service manual.

Essential Spare Parts Every R160W9A Owner Should Carry

Preventive Maintenance: Replacing Bearings on Hyundai Excavators

How to Inspect Undercarriage Parts of Excavator 2026

Best AC compressor for excavator manufacturers and supplier brands

faq

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

K5V212DPH1J8R-9NG4-AV Hydraulic Pump - Construction Machinery Spare Parts fits EC300D EC350D EC380D R335LC-9V

The K5V212DPH1J8R-9NG4-AV is an OEM-compatible variable displacement axial piston main hydraulic pump, custom-engineered for Volvo EC300D/EC350D/EC380D and Hyundai R335LC-9V 30-38 ton excavators.

Key Features

· High-power output: 212cc displacement, max pressure 34.3 MPa, 1800 rpm rated speed—matches 150-190kW engine power for 30-38 ton excavators, ensuring efficient high-load operation.

· Precision flow control: Electro-hydraulic proportional control adjusts output per workload, cutting fuel consumption by 8% vs. standard pumps while maintaining smooth actuator response.

· Direct OEM fit: Exact mounting points, hydraulic ports, and SAE J518 flanges enable plug-and-play installation without system reconfiguration or adapter parts.

· Durable components: Hardened cylinder block, chrome-plated pistons, and wear-resistant valve plate extend service life; integrated pressure relief valve prevents overload damage.

Compatible Models & Part Numbers

· Volvo Excavators: EC300D, EC350D, EC380D

· Hyundai Excavators: R335LC-9V

· Part Number: K5V212DPH1J8R-9NG4-AV

· Interchangeable References: K5V212DPH-9N series; matches original main pump specs for above models

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879