Understanding R160W9A Parts Compatibility and Fit Guide

- Understanding R160W9A Parts Compatibility and Fit Guide

- Why correct excavator parts compatibility matters

- Product overview: SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub

- Which models does ZGAQ-03591 hub fit? Compatibility matrix

- How to verify physical fit before purchase

- Key dimensions and fit points to measure

- Material, performance and operating conditions

- Installation best practices for excavator parts (hub-focused)

- Common fitment problems and how to troubleshoot them

- Maintenance practices to maximize hub life

- Why choose SPARKLING MACHINERY ZGAQ-03591 hubs: brand strengths

- How to validate a supplier and protect your purchase

- Frequently Asked Questions (FAQ)

- Contact and product viewing / purchase CTA

- References and sources

Understanding R160W9A Parts Compatibility and Fit Guide

Why correct excavator parts compatibility matters

Using the right parts for an excavator — especially undercarriage components like hubs — is critical for safety, machine uptime, and lifecycle cost. Incorrect fitment can cause excessive wear, uneven track tension, axle damage, travel instability, and unexpected downtime. For owners and maintenance teams, understanding how to check compatibility for models such as the R160W9A and its close siblings (R170W7, R170W7A, R170W9) is an essential skill when sourcing reliable excavator parts.

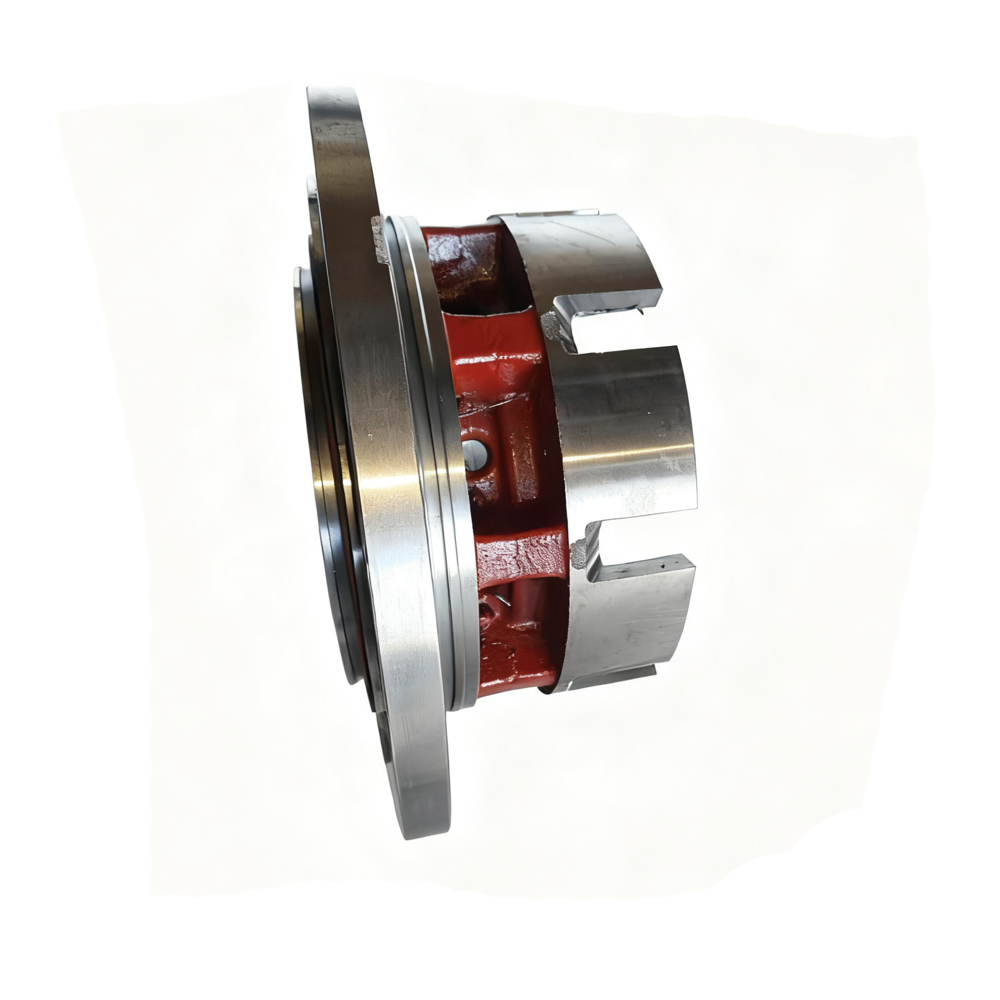

Product overview: SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

Which models does ZGAQ-03591 hub fit? Compatibility matrix

Manufacturers and parts suppliers typically publish a cross-reference showing which part numbers fit which excavator models. SPARKLING MACHINERY advertises this hub as compatible with Hyundai R160W9A, R170W7, R170W7A and R170W9 undercart systems when produced to OEM standard ZGAQ-03591. Below is a concise compatibility summary to help you quickly assess fit before purchase or installation.

| Excavator Model | Compatible (ZGAQ-03591) | Notes |

|---|---|---|

| Hyundai R160W9A | Yes | Direct replacement when hub produced to ZGAQ-03591 dimension and tolerance spec. |

| Hyundai R170W7 | Yes | Fit confirmed under same OEM spec; verify axle spline/bolt pattern before install. |

| Hyundai R170W7A | Yes | Interchangeable variant; check any model-year changes to axle components. |

| Hyundai R170W9 | Yes | Compatible for common wheel/axle assemblies; confirm seal and bearing match. |

Source: SPARKLING MACHINERY product spec (ZGAQ-03591) and Hyundai parts cross-references. Always confirm model-year specifics with the vendor or the OEM parts catalog prior to purchase.

How to verify physical fit before purchase

Before ordering or installing any hub or undercarriage component, perform a structured verification to avoid costly returns and downtime. Follow these steps:

- Part number confirmation — Match the OEM part number (ZGAQ-03591) and any OEM cross-reference numbers on the supplier invoice or catalog.

- Compare OEM drawings — Request dimensional drawings or a spec sheet from the supplier and compare critical dimensions to your machine’s service manual (bore diameter, bolt circle diameter, number of bolts, overall flange thickness, bearing seat depth).

- Visual and serial checks — If replacing an existing hub, record and photograph bolt pattern, hub flange, spline count and seal type. Use these photos to confirm supplier part equivalency.

- Check service manual values — Confirm axle spline count, shaft diameter and pilot dimensions from the OEM service manual. If you don’t have the manual, request the relevant pages from an authorized dealer.

- Confirm auxiliary components — Bearings, seals and fasteners often change between sub-models. Ensure the supplier includes or recommends compatible bearings/seals where applicable.

Key dimensions and fit points to measure

For a reliable fit, measure and confirm the following dimensions. If any dimension differs beyond the tolerance shown in the OEM manual, the hub may not fit or may cause premature failure.

- Inner bore diameter (axle mating surface) — ensures correct press fit or spline engagement.

- Shaft spline count and profile — mismatch will prevent drive engagement.

- Bolt circle diameter (BCD) and bolt hole size — critical for secure mounting.

- Flange thickness and hub overall width — affects bearing preload and clearance.

- Seat depth for bearings and seals — incorrect depth can cause leakage or bearing misalignment.

Material, performance and operating conditions

Undercarriage hubs must resist impact, abrasive wear, and thermal cycling. The SPARKLING MACHINERY hub claims compliance with the ZGAQ-03591 OEM standard and specified performance across -30°C to 100°C. Key material and performance considerations include:

- Material composition — Hubs are commonly made from high-strength cast steel or ductile iron and may receive heat treatment to improve fatigue strength.

- Heat treatment & hardness — Case-hardening or quenching/tempering improves wear resistance of bearing seats and mating surfaces.

- Surface treatment — Protective coatings reduce corrosion in wet or marine environments.

- Quality control — Dimensional inspection and material certification (chemical/physical) are important to ensure long-term reliability.

These characteristics directly affect life expectancy in abrasive or heavy-load applications such as quarrying or mining.

Installation best practices for excavator parts (hub-focused)

Proper installation is as important as correct part selection. Follow these best practices to ensure safe, long-lasting performance:

- Pre-install inspection — Clean all mating surfaces, inspect axle shaft for wear or damage, and replace bearings/seals if worn.

- Use OEM torque values — Always tighten hub bolts to the torque specified in the OEM service manual. If OEM torque is unavailable, consult an authorized dealer. Under- or over-torquing damages bolts and components.

- Use proper tools — A calibrated torque wrench, hydraulic press for bearing installation, and alignment tools for bolt circles are recommended.

- Install with correct bearings/seals — Even if the hub dimensions match, mismatched bearing types will cause premature failure.

- Run-in and recheck — After initial operation (first 50–100 hours), re-torque bolts and inspect for leaks or unusual noise.

Common fitment problems and how to troubleshoot them

Even when a hub is listed as compatible, real-world issues can arise. Here are frequent problems and practical fixes:

- Bolt holes don’t align — Confirm BCD and orientation; check that the hub is the correct left/right variant if applicable.

- Excessive end play after installation — Verify bearing seat depth and bearing selection; preload may be insufficient.

- Leakage at seals — Ensure the hub’s seal seat dimensions match the seal; seating surface must be clean and undamaged.

- Noise or rough travel — Check spline engagement and bearing condition; partial spline engagement or damaged splines cause vibration.

- Premature wear — Reevaluate material grade, heat treatment, and application severity; consider a higher-spec replacement if operating in extreme conditions.

Maintenance practices to maximize hub life

Routine maintenance extends lifespan and reduces the total cost of ownership for excavator parts:

- Regular inspections — Check for cracks, corrosion, and flange wear during scheduled maintenance intervals.

- Lubrication & seals — Maintain proper lubrication levels and inspect seals for leakage; replace seals proactively when signs of age appear.

- Monitor track tension — Incorrect track tension places abnormal loads on hubs; maintain tension per OEM guidelines.

- Record keeping — Track hours and conditions (abrasive environment, heavy loads) to plan preventative replacements before failure.

Why choose SPARKLING MACHINERY ZGAQ-03591 hubs: brand strengths

When selecting replacement excavator parts, procurement teams weigh price, quality, and lead time. SPARKLING MACHINERY positions the ZGAQ-03591 hub as a high-quality alternative that meets Hyundai OEM standards. Key advantages include:

- OEM-equivalent standard — Built to meet ZGAQ-03591 specification for direct interchangeability with listed Hyundai models.

- Wide temperature tolerance — Rated for -30°C to 100°C, making them suitable for varied climates.

- Quality control — Suppliers typically provide material/test certificates and dimensional inspection reports upon request.

- Competitive lead times and inventory — Many reputable Chinese manufacturers maintain inventory for fast dispatch, which reduces machine downtime compared with OEM lead times in some regions.

- Cost-effectiveness — Lower purchase price while maintaining comparable performance when parts are produced to OEM specs and validated through QC.

Always verify certificates and request inspection reports to ensure the part you receive matches the claimed standards.

How to validate a supplier and protect your purchase

To minimize risk when sourcing excavator parts:

- Request material and dimensional certificates as part of the purchase order.

- Ask for references and photos of batch inspection reports.

- Where possible, purchase through an authorized distributor who can back the warranty and provide technical support.

- Use small trial orders for new suppliers to validate quality before committing to large volume buys.

Frequently Asked Questions (FAQ)

Q1: Will the SPARKLING MACHINERY ZGAQ-03591 hub fit my R160W9A without modification?

A1: If the hub is produced to the ZGAQ-03591 specification and you have confirmed axle spline, bore dimension, and bolt circle match your machine, it should fit without modification. Always cross-check the dimensions with your service manual or an authorized dealer.

Q2: How do I confirm the hub’s material and heat treatment?

A2: Request a material test certificate (chemical composition) and a hardness report or heat-treatment certificate from the supplier. For critical undercarriage parts this documentation is a standard part of quality control.

Q3: Are aftermarket hubs as reliable as OEM hubs?

A3: Quality varies. High-quality aftermarket parts made to OEM specs and with proper QC can perform comparably to OEM parts at a lower cost. The key is verifying specifications and traceable quality documentation.

Q4: What torque should I use for hub bolts?

A4: Use the torque values specified in the OEM service manual for your machine. If unavailable, obtain torque figures from the supplier or an authorized Hyundai dealer. Incorrect torque can lead to bolt failure or component damage.

Q5: Can I replace bearings and seals myself?

A5: Technically yes if you have the correct tools (press, bearing drivers, torque wrench) and mechanical experience. For critical fits and press-in bearings, many operators prefer professional service to ensure proper installation and alignment.

Contact and product viewing / purchase CTA

After reviewing R160W9A parts compatibility, you’ll want to explore how this compares to the R170W7 excavator parts and key components. This guide highlights the essential parts for the R170W7 model, ensuring you're fully informed about the correct components and their functionality for your machinery. If you need a certified replacement hub for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators, request the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub product sheet and QC documentation. Contact our sales team for price, lead time, and a dimensional drawing to confirm fitment: sales@sparklingmachinery.example or call +86-XXX-XXXX-XXXX. For urgent machine downtime, request expedited inspection photos and a certificate of conformity before shipment.

References and sources

The guidance in this article is drawn from equipment manufacturer documentation and industry best practices. Verify machine-specific values with your OEM service manual and supplier documentation.

- Hyundai Construction Equipment — Official parts and service information (Hyundai CE parts catalogs and manuals). Example: https://www.hyundai-ce.com/en

- SPARKLING MACHINERY product specifications — ZGAQ-03591 hub data and QC documents (request from supplier).

- ISO 9001 — Quality management practices for parts manufacturing: https://www.iso.org/iso-9001-quality-management.

- ForConstructionPros — Articles on undercarriage maintenance and parts selection: https://www.forconstructionpros.com

- Equipment World / industry best-practice articles on undercarriage care and torque procedures: https://www.equipmentworld.com

Note: For exact torque specifications, spline counts, and diameters, always consult the OEM service manual or an authorized dealer to avoid model-year variations and to maintain safety and warranty compliance.

The B2B Buyer’s Guide to Hydraulic Parts for Excavators | SPARKLING Ultimate Insights

Wholesale Wheel excavator rear drivetrain manufacturer and supplier

The Environmental Impact of Excavator Hydraulic Fluids and How to Mitigate It

Top Specs to Check: K9003219 Pulley Idler for Wheel Loaders

faq

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879