Supplier Checklist for HYUNDAI EXCAVATOR PARTS Procurement

- 1. Verify Technical Compatibility and Part Fit

- 1.1 Confirm OEM Part Numbers and Cross-References

- 1.2 Check Dimensions, Tolerances and Sealing

- 1.3 Assess Material and Heat Treatment

- 2. Quality Systems, Standards and Traceability

- 2.1 Supplier Quality Management and Certifications

- 2.2 Material Traceability and Batch Documentation

- 2.3 Test Reports and Performance Verification

- 3. Supply Chain, Logistics and Commercial Terms

- 3.1 Lead Times, MOQ and Local Availability

- 3.2 Packaging, Handling and Shipping Conditions

- 3.3 Pricing Structure and Warranty Terms

- 4. Inspection, Testing and On-Site Validation

- 4.1 Incoming Inspection Checklist

- 4.2 Field Trial and Failure Monitoring

- 4.3 Spare Parts Strategy and Predictive Replacement

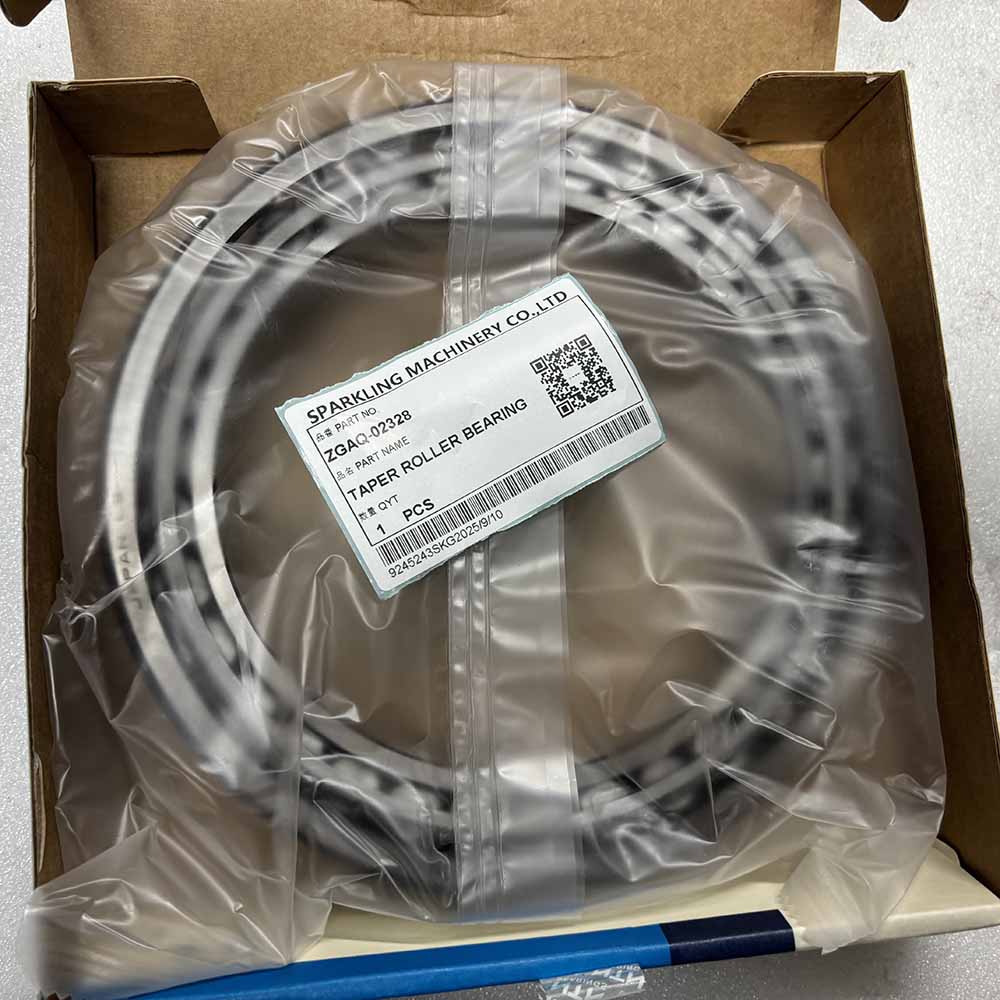

- Product Spotlight: SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing

- Comparison Table: ZGAQ-02328 vs Typical Alternatives

- Supplier Evaluation Scorecard and Best Practices

- Scorecard Criteria

- On-Site Supplier Audits and Sampling

- Data-Driven Procurement

- References and Standards

- Frequently Asked Questions (FAQ)

- Q1: How do I confirm ZGAQ-02328 will fit my Hyundai excavator?

- Q2: What inspection steps should be done upon receipt?

- Q3: Is an aftermarket bearing reliable for heavy-duty use?

- Q4: What warranty terms should I require from a supplier?

- Q5: How can I reduce procurement lead time for critical parts?

Supply chain teams and maintenance planners seeking HYUNDAI EXCAVATOR PARTS must balance technical compatibility, quality assurance, logistics, and regulatory compliance. This checklist helps procurement professionals and fleet managers evaluate suppliers of critical rotating and structural components—such as bearings, pins and bushings, final drives and undercarriage parts—so replacement parts (e.g., the ZGAQ-02328 tapered roller bearing) perform reliably across HW210, R200W7, R200W7A and R210W-9 machines and in diverse regional operating conditions.

1. Verify Technical Compatibility and Part Fit

1.1 Confirm OEM Part Numbers and Cross-References

Always start by matching the OEM part number. For example, SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing is manufactured to meet Hyundai OEM Part No.: ZGAQ-02328. Cross-checking OEM numbers avoids costly mismatches—especially for critical rotating components that integrate with the swing bearing, final drive, or main shaft. Use official parts catalogs from Hyundai Construction Equipment to confirm fit for models such as HW210, R200W7, R200W7A and R210W-9 (Hyundai CE).

1.2 Check Dimensions, Tolerances and Sealing

Obtain dimensional drawings and tolerance tables from the supplier. Tapered roller bearings must meet radial and axial tolerance bands to avoid premature wear in the carrier/shaft assembly. Verify bore diameter, outer diameter, width, cone geometry and the sealing arrangement—these impact compatibility with components like the swing gear, shaft journal and final drive. Refer to bearing tolerance references for guidance (roller bearing overview).

1.3 Assess Material and Heat Treatment

High-load parts of an excavator—pins, bushings, bearings—require appropriate case-hardening and core toughness. Confirm material specs (bearing steel grade), quench & temper processes and surface treatments. For ZGAQ-02328, ask for metallurgical certificates and hardness maps to ensure load capacity and wear resistance meet or exceed OEM expectations.

2. Quality Systems, Standards and Traceability

2.1 Supplier Quality Management and Certifications

Only source from suppliers with documented quality systems. Certifications such as ISO 9001 indicate process control; for critical components, look for process control documentation and supplier audit reports. See ISO's overview for quality management: ISO 9001.

2.2 Material Traceability and Batch Documentation

Require batch-level traceability: raw material certificates, heat numbers, manufacturing dates and QC test records. For bearings and other rotating parts, traceability enables root-cause analysis if a field failure occurs and helps meet warranty terms.

2.3 Test Reports and Performance Verification

Ask for dynamic and static load test results, noise and vibration analysis, and surface finish reports. Reputable vendors provide test data showing how a tapered roller bearing performs under combined radial and axial loading conditions relevant to excavator swing and travel systems. Where available, reference independent laboratory reports or supplier-run lifecycle tests.

3. Supply Chain, Logistics and Commercial Terms

3.1 Lead Times, MOQ and Local Availability

Confirm lead times and minimum order quantities (MOQ). For fleets operating across regions, factor in local inventory availability for quick turnaround—especially for essential parts of an excavator like buckets, pins/bushings, track chains and bearings. Supplier proximity impacts downtime costs dramatically.

3.2 Packaging, Handling and Shipping Conditions

Components such as tapered roller bearings must be packaged to prevent contamination and corrosion during transit. Verify desiccant use, rust-preventive paper, and handling instructions. Ask for shipping samples or photos and ensure the supplier uses temperature- and moisture-controlled packaging when required.

3.3 Pricing Structure and Warranty Terms

Compare unit price, bundled discounts, and warranty scope. Warranties should explicitly cover manufacturing defects and premature wear for a defined period or operating hours. Confirm repair/replacement procedures and who bears freight for warranty returns.

4. Inspection, Testing and On-Site Validation

4.1 Incoming Inspection Checklist

Implement a standard inspection on receipt: visual check for damage, verification of part number and serial/batch IDs, dimensional checks with calibrated gauges, and lubrication/seal inspection. Record results in the ERP or maintenance management system to maintain part history for each excavator in the fleet.

4.2 Field Trial and Failure Monitoring

For critical rotating parts like ZGAQ-02328, run a controlled field trial with vibration monitoring and periodic torque checks. Monitor for abnormal temperature rise, noise, or oil contamination. Use condition monitoring to capture early warning signs before catastrophic failures.

4.3 Spare Parts Strategy and Predictive Replacement

Balance stocking critical spares against costs. For excavator parts—undercarriage components, hydraulic pumps, swing bearings and tapered rollers—use usage data to set reorder points. Predictive replacement based on operating hours and condition data reduces emergency purchases and downtime.

Product Spotlight: SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing

SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing is a core rotating component for Hyundai excavators (construction/mining use). It withstands combined radial and axial loads, ensuring smooth rotation of key shaft parts.

Meeting Hyundai OEM standards (Part No.: ZGAQ-02328), it delivers high wear resistance and load capacity, guaranteeing seamless compatibility and long-term stable operational performance.

This bearing is listed as compatible with models HW210, R200W7, R200W7A and R210W-9. When procuring, compare the ZGAQ-02328's dynamic load rating, grease retention, seal type and warranty to alternatives. Reliable bearings reduce stress on adjacent parts of an excavator such as the swing housing, final drive and axle assemblies.

Comparison Table: ZGAQ-02328 vs Typical Alternatives

| Feature | ZGAQ-02328 (SPARKLING MACHINERY) | Generic Aftermarket Bearing | High-End OEM Equivalent |

|---|---|---|---|

| OEM Part Match | Meets Hyundai Part No. ZGAQ-02328 | May require cross-reference | Direct Hyundai OEM supply |

| Material & Heat Treatment | Bearing steel with controlled heat treatment; certificates provided | Variable; limited traceability | Strict metallurgy & traceability |

| Load Capacity | Engineered for combined radial/axial loads | Lower rated in many cases | Highest rated, validated by OEM tests |

| Warranty | Standard supplier warranty with batch trace | Shorter/limited | OEM warranty & service |

| Price | Competitive (value-oriented) | Lowest | High Quality |

Supplier Evaluation Scorecard and Best Practices

Scorecard Criteria

Use a scoring matrix to rank suppliers across: technical compliance, quality certification, traceability, lead time, after-sales support, warranty and price. Weight criteria according to fleet priorities—e.g., uptime-driven operations should prioritize availability and warranty over lowest price.

On-Site Supplier Audits and Sampling

Perform periodic supplier audits focusing on production controls, machining tolerances, heat-treatment records and packaging processes. Request production samples—measure run-to-run variability and assemble into representative systems (e.g., install the tapered roller bearing into a test hub to validate fit and runout).

Data-Driven Procurement

Integrate supplier performance KPIs into procurement dashboards: % on-time delivery, first-pass inspection rate, field failure rate (within warranty), and mean time between failures (MTBF) for assemblies that use the supplied parts. Use this data to negotiate improved terms or switch suppliers if needed.

References and Standards

For technical and industry best practices consult authoritative resources such as Wikipedia's overview of excavators (Excavator — Wikipedia), bearing technology references from major manufacturers (e.g., SKF tapered roller bearings), and quality standards such as ISO 9001 for supplier quality systems (ISO 9001). For industry context and equipment lifecycle guidance see the Association of Equipment Manufacturers (AEM).

Frequently Asked Questions (FAQ)

Q1: How do I confirm ZGAQ-02328 will fit my Hyundai excavator?

A: Match the OEM part number and cross-reference the parts catalog for your model (HW210, R200W7, R200W7A, R210W-9). Request dimensional drawings and supplier fitment confirmation. When possible, validate by measuring the removed part and comparing bore/OD/width tolerances.

Q2: What inspection steps should be done upon receipt?

A: Perform visual checks for damage, verify part and batch numbers, perform dimensional verification with calibrated gauges, and inspect seals and lubrication. Record results in your maintenance system for future traceability.

Q3: Is an aftermarket bearing reliable for heavy-duty use?

A: Reliability depends on supplier quality controls and materials. Choose suppliers with ISO-certification, batch traceability, and test reports. Compare dynamic load ratings and material specifications to OEM equivalents. Field trials and condition monitoring are recommended before fleet-wide adoption.

Q4: What warranty terms should I require from a supplier?

A: Require clear warranty coverage for manufacturing defects and premature wear (expressed in months or operating hours), defined return procedures, and responsibility for freight on warranty claims. Insist on batch-level traceability to support claims.

Q5: How can I reduce procurement lead time for critical parts?

A: Maintain local safety stock for essential parts of an excavator (bearings, pins, seals, track parts), establish regional distribution agreements, and qualify multiple vetted suppliers to prevent single-source delays.

Ready to evaluate or purchase the SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing or other HYUNDAI EXCAVATOR PARTS? Contact our parts team for certificates, sample testing, lead times and pricing. Email Sales or view the product page: ZGAQ-02328 product page.

Long-Term Care Tips for Hyundai Excavator Components

Selecting Hydraulic Hose for Volvo EC480D EC480DHR (VOE14578951)

Compatibility Guide: Bearings for R210W-9 and R200W7A

How Excavator Hydraulic Systems Contribute to Fuel Efficiency

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

K5V212DPH1J8R-9NG4-AV Hydraulic Pump - Construction Machinery Spare Parts fits EC300D EC350D EC380D R335LC-9V

The K5V212DPH1J8R-9NG4-AV is an OEM-compatible variable displacement axial piston main hydraulic pump, custom-engineered for Volvo EC300D/EC350D/EC380D and Hyundai R335LC-9V 30-38 ton excavators.

Key Features

· High-power output: 212cc displacement, max pressure 34.3 MPa, 1800 rpm rated speed—matches 150-190kW engine power for 30-38 ton excavators, ensuring efficient high-load operation.

· Precision flow control: Electro-hydraulic proportional control adjusts output per workload, cutting fuel consumption by 8% vs. standard pumps while maintaining smooth actuator response.

· Direct OEM fit: Exact mounting points, hydraulic ports, and SAE J518 flanges enable plug-and-play installation without system reconfiguration or adapter parts.

· Durable components: Hardened cylinder block, chrome-plated pistons, and wear-resistant valve plate extend service life; integrated pressure relief valve prevents overload damage.

Compatible Models & Part Numbers

· Volvo Excavators: EC300D, EC350D, EC380D

· Hyundai Excavators: R335LC-9V

· Part Number: K5V212DPH1J8R-9NG4-AV

· Interchangeable References: K5V212DPH-9N series; matches original main pump specs for above models

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879