The Evolution of Excavator Hydraulic Systems: From Basics to Advanced

- The Evolution of Excavator Hydraulic Systems: From Basics to Advanced — Excavator Hydraulic Parts

- Hydraulic fundamentals and core Excavator Hydraulic Parts

- Early systems: open-center and fixed-displacement pump designs

- Shift to variable-displacement and load-sensing systems

- Electro-hydraulic control and proportional valves

- Closed-center vs open-center vs load-sensing: practical differences

- High-pressure systems and modern component demands

- Typical pressure & flow by excavator size

- Energy recovery and hybrid hydraulic integrations

- Control intelligence, diagnostics and predictive maintenance

- Materials, wear parts and sealing technology

- Choosing the right Excavator Hydraulic Parts: practical tips

- SPARKLING MACHINERY: Your partner for Excavator Hydraulic Parts

- Maintenance checklist for longer component life

- Common troubleshooting and quick checks

- Future trends: electrification, modular hydraulics and AI optimization

- FAQ — Frequently Asked Questions about Excavator Hydraulic Parts and Systems

- Q: What pressure range should I expect from modern excavator hydraulic systems?

- Q: How do I choose the right hydraulic pump replacement?

- Q: Can I mix aftermarket Excavator Hydraulic Parts with OEM parts?

- Q: How often should hydraulic oil be tested or replaced?

- Q: Are hybrid hydraulic excavators worth it?

- Q: How can SPARKLING MACHINERY help me source the right parts?

The Evolution of Excavator Hydraulic Systems: From Basics to Advanced — Excavator Hydraulic Parts

Excavator hydraulic systems are the heart of modern earthmoving equipment. Over the last decades they have moved from simple open-center and fixed-displacement designs to sophisticated load-sensing, electro-hydraulic and hybrid architectures. For technicians, fleet managers and parts buyers, understanding this evolution helps you choose the right Excavator Hydraulic Parts, improve uptime and lower operating costs.

Hydraulic fundamentals and core Excavator Hydraulic Parts

At their simplest, hydraulic systems convert mechanical power into pressurized fluid to do work. Key components every excavator uses include hydraulic pumps (often axial piston pumps for modern machines), hydraulic motors, control valves, cylinders (rams), hoses, filters, accumulators, hydraulic oil and electronic control units (ECUs). Matching parts by specification — maximum pressure, flow rate, porting and control type — is essential when replacing or upgrading components.

Early systems: open-center and fixed-displacement pump designs

Early hydraulic excavators (mid-20th century to 1980s) used fixed-displacement pumps and open-center valve systems. These systems were simple and rugged but inefficient: pumps delivered continuous flow whether the actuator needed it or not, returning excess to the tank. This simplicity favored low initial cost and easier repairs but consumed more fuel and caused heat buildup. Common Excavator Hydraulic Parts in this era were gear and vane pumps, spool valves, and simple filters.

Shift to variable-displacement and load-sensing systems

By the late 1980s and 1990s, variable-displacement axial piston pumps and load-sensing (LS) systems became mainstream in excavators. Load-sensing pumps adjust flow according to demand, while pressure-compensating valves maintain stable operation. The result: significantly improved fuel efficiency, reduced heat, smoother multi-function operation and better control responsiveness.

Benefits of load-sensing systems:

- Higher fuel efficiency — pump supplies only needed flow

- Lower heat generation — less wasted flow returned to tank

- Smoother simultaneous operations — flow sharing between functions

Electro-hydraulic control and proportional valves

Modern excavators integrate electronic controls with hydraulic actuation. Electro-hydraulic proportional valves (EPVs) and electro-hydraulic servo valves allow precise flow and pressure modulation under ECU supervision. This enables features like creep mode, boom speed control, automatic return-to-dig and load-holding controls. Communication typically uses CAN bus protocols to coordinate pumps, engine management and operator inputs.

Closed-center vs open-center vs load-sensing: practical differences

Understanding valve architecture matters when sourcing Excavator Hydraulic Parts or diagnosing issues:

| System | Typical Pump | Efficiency | Responsiveness | Typical Pressure Range | Best For |

|---|---|---|---|---|---|

| Open-center | Fixed-displacement | Low | Moderate | Up to 200–250 bar | Simple, low-cost machines |

| Closed-center (electro-hydraulic) | Variable or multiple pumps | Medium | High | 250–320 bar | Precise control, multi-function |

| Load-sensing (LS) | Variable-displacement axial piston | High | High | 250–350 bar | Fuel efficient, high productivity |

High-pressure systems and modern component demands

Contemporary excavators often operate between 250 and 350 bar (approximately 3,600–5,075 psi), depending on machine size and function. Higher system pressure allows smaller components and more force but increases demands on seals, hoses, fittings and valves. Typical flow rates depend on machine class — small mini-excavators might use 40–120 L/min while large class machines can exceed 300–500 L/min from one or more pump circuits.

Typical pressure & flow by excavator size

| Machine Class | Typical Operating Pressure | Typical Main Pump Flow | Common Excavator Hydraulic Parts |

|---|---|---|---|

| Mini (≤6 t) | 200–250 bar | 40–120 L/min | Mini cylinders, compact pumps, small hoses, cartridge valves |

| Medium (6–20 t) | 250–320 bar | 120–250 L/min | Axial piston pumps, proportional valves, mid-size cylinders |

| Large (>20 t) | 300–350 bar | 250–600 L/min | High-pressure pumps, heavy-duty cylinders, large manifolds |

Energy recovery and hybrid hydraulic integrations

Recent years have seen hybrid excavators that capture and reuse energy — for example during swing braking or boom lowering — or use electric drives to reduce engine load. Manufacturers like Komatsu, Hitachi and Volvo introduced hybrid models (e.g., Komatsu HB series, certain Hitachi hybrid variants) that show fuel savings in stop-and-go or digging applications. Hybrid designs place new demands on Excavator Hydraulic Parts: energy storage components, control software, and power electronics in addition to traditional hydraulic hardware.

Control intelligence, diagnostics and predictive maintenance

IoT, telematics and onboard diagnostics now allow predictive maintenance: vibration analysis, hydraulic oil condition monitoring, and fault code histories help prevent catastrophic failures. Parts suppliers increasingly offer smart sensors and compatible ECUs so Excavator Hydraulic Parts (like sensors, proportional valves, pumps) integrate with fleet management systems for condition-based servicing and extended component life.

Materials, wear parts and sealing technology

As pressures increased, materials and seals evolved. High-strength steels, hardened surfaces, improved coatings (e.g., nitride, chrome plating) and advanced elastomers for seals improved durability. Wear parts such as bucket pins, rod ends, valve seats and pump swash plates require proper matching to OEM specs. Correct part selection reduces leakage, extends service intervals and protects core components.

Choosing the right Excavator Hydraulic Parts: practical tips

- Match specifications: pressure rating, flow capacity, port sizes and control type (mechanical/electronic).

- Prefer OEM-equivalent or higher spec seals and hoses for high-pressure systems.

- Use correct hydraulic oil grade and change intervals — oil cleanliness (ISO cleanliness codes) directly affects component life.

- Inspect filters and return-line filters; use micron ratings recommended by the manufacturer.

- When retrofitting controls, verify ECU compatibility, CAN protocols and safety interlocks.

SPARKLING MACHINERY: Your partner for Excavator Hydraulic Parts

SPARKLING MACHINERY, founded in 2013, focuses on high-quality excavator parts with an emphasis on stability, precision and perseverance. We supply a broad range of Excavator Hydraulic Parts — pumps, valves, cylinders, hoses, filters and accessories — compatible with major brands such as Caterpillar, Komatsu, Hitachi and Volvo. Through strict manufacturing controls and full testing, our components are built to operate reliably under various conditions. We provide tailored solutions, technical support and global after-sales service to help customers reduce costs while ensuring performance. Our vision is to become the world's top excavator parts manufacturer.

Maintenance checklist for longer component life

Regular maintenance reduces downtime. Key actions include:

- Hydraulic oil analysis every 500–1000 hours (depending on machine and operating conditions).

- Replace return-line and suction filters per OEM schedule; inspect breather and breathers’ screens.

- Inspect hoses and fittings for abrasion and leaks; replace aging hoses proactively.

- Monitor operating temperatures; excessive heat is a primary cause of oil degradation and seal failure.

- Use OEM or high-quality aftermarket Excavator Hydraulic Parts to retain system tolerances.

Common troubleshooting and quick checks

Problems often trace back to a few common sources:

- Slow or weak movement — check pump flow, control valve spool wear and actuator leaks.

- Overheating — check for excessive return flow, blocked cooling circuits, or oversized relief settings.

- Spongy controls — verify oil level, contamination levels, and worn valve spools or seals.

- Random faults — check electronic communication, sensor inputs, and ground connections.

Future trends: electrification, modular hydraulics and AI optimization

Looking forward, expect more electrified and modular hydraulic subsystems, wider adoption of energy recovery, and AI-driven control loops that optimize pump displacement and valve openings in real time. This will influence the design and sourcing of Excavator Hydraulic Parts: more integrated electro-hydraulic actuators, modular manifolds and smart sensors will become standard. For parts suppliers, adaptability and software compatibility will be as important as traditional mechanical tolerances.

FAQ — Frequently Asked Questions about Excavator Hydraulic Parts and Systems

Q: What pressure range should I expect from modern excavator hydraulic systems?

A: Modern excavators typically operate between 200 and 350 bar. Mini-excavators often run at 200–250 bar, medium machines 250–320 bar, and large machines can reach 300–350 bar. Always check the OEM specification for exact ratings.

Q: How do I choose the right hydraulic pump replacement?

A: Match displacement, maximum pressure rating, mounting flange, shaft type and control method (fixed vs variable). If your machine uses load-sensing technology, ensure the pump supports LS feedback controls.

Q: Can I mix aftermarket Excavator Hydraulic Parts with OEM parts?

A: Yes, but ensure aftermarket parts meet or exceed OEM specifications for pressure, flow, materials and tolerances. For electronic components, ensure compatibility with your ECU and communication protocols.

Q: How often should hydraulic oil be tested or replaced?

A: Oil condition should be checked regularly; many fleets do oil analysis every 500–1,000 hours. Replace oil per OEM recommendation or when contamination, viscosity shift or oxidation is detected.

Q: Are hybrid hydraulic excavators worth it?

A: Hybrids deliver fuel savings and lower emissions in suitable use cases (frequent cycles, swing braking). They have higher initial cost and more complex parts (energy storage), so evaluate payback based on operating profile and fuel costs.

Q: How can SPARKLING MACHINERY help me source the right parts?

A: SPARKLING MACHINERY provides OEM-compatible Excavator Hydraulic Parts, customized solutions, technical consultation and global support. We can match specifications, provide tested components and advise on system upgrades to improve efficiency and uptime.

For expert advice or to source high-quality Excavator Hydraulic Parts compatible with your machine model, contact SPARKLING MACHINERY for detailed specifications and service support.

Common Hydraulic System Issues in Excavators and Their Solutions

The B2B Buyer’s Guide to Excavator Track Shoes

How to Verify Compatibility: LC52S00019P1 Low Pressure Sensor

Wholesale excavator LH control column manufacturer and supplier

faq

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

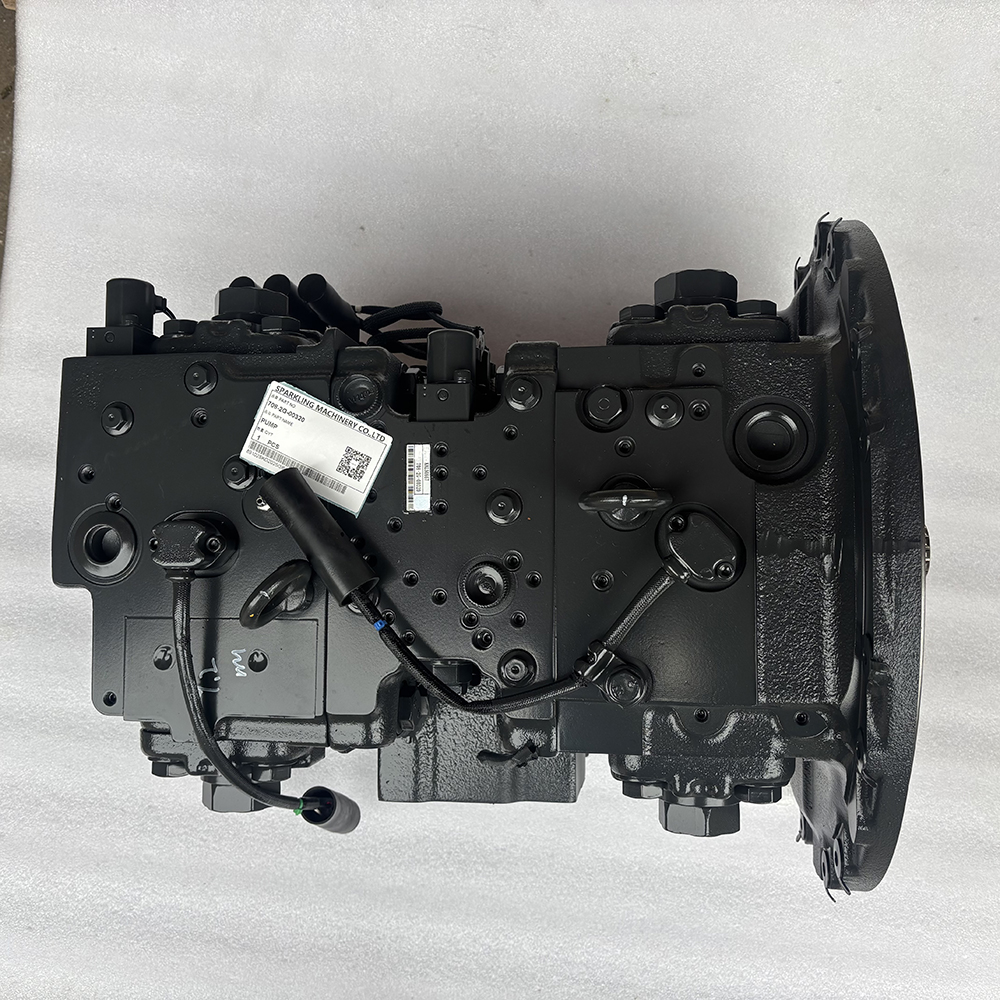

KOMATSU Made In CHINA SPARKLING MACHINERY 708-2G-00320 Pump

SPARKLING MACHINERY 708-2G-00320 Pump, a premium China-made hydraulic component, stands as a vital power transmission core for excavators. Engineered to original equipment standards, this pump ensures seamless integration with compatible excavator models, enabling direct, hassle-free installation without modifications.

Equipped with advanced hydraulic control technology, it delivers precise flow and pressure regulation in real time, optimizing operational smoothness and energy efficiency during digging, lifting, and slewing tasks. Crafted from high-strength materials, it undergoes rigorous quality testing to withstand harsh construction environments, complying with strict industry standards for long-term reliability. Backed by professional technical support and cost-effective performance, it’s the trusted choice to enhance your equipment’s productivity and reduce downtime.

Rexroth Relief Valve 04950403 R901102333 – 350 Bar Screw‑In Cartridge

The Rexroth Relief Valve 04950403 (part no. R901102333) is a precision-engineered screw-in cartridge valve designed for hydraulic systems in excavators and industrial machinery. This robust, direct-acting spool-type valve offers pressure reducing and relieving capabilities, withstanding up to 350 bar of maximum operating pressure and supporting flow rates around 30 L/min. Constructed with quality materials and standard CAAN cavity compatibility, it ensures responsive, leak-free hydraulic control under demanding conditions.

Premium XKCH-00022 solenoid valve fits Hyundai R125LCR-9A, R145CR9, R160LC9A, and R180LC9S excavators. Reliable hydraulic control part from SPARKLING

The XKCH-00022 Solenoid Valve is a precision-engineered hydraulic control component used in multiple Hyundai crawler excavators, including models R125LCR-9A, R145CR9, R160LC9A, and R180LC9S.

This solenoid valve plays a vital role in directing hydraulic fluid flow in key systems such as travel, swing, or attachment control. Engineered for responsive performance and long-lasting durability, this part ensures accurate actuation and helps maintain overall machine efficiency.

SK200-6 SK210-6 KOBELCO EXCAVATOR K3V112DT YN10V00007F1 HYDRAULIC MAIN PUMP ASSY

The K3V112DT Hydraulic Main Pump Assembly (YN10V00007F1) is a precision-engineered OEM component specifically designed for Kobelco SK200-6 and SK210-6 excavators. Manufactured to exacting standards, this pump delivers exceptional hydraulic efficiency, durability, and consistent performance under heavy-duty operating conditions. Its optimized design ensures seamless integration with your Kobelco machinery, minimizing downtime and maximizing productivity. Ideal for replacements or overhauls, this genuine assembly guarantees compatibility and reliability, backed by stringent quality control. Trust the K3V112DT to restore your excavator’s hydraulic system to peak performance.

Sparkling Machinery Co.,Ltd

foreverlucia1