The Role of Hydraulic Pumps in Excavator Efficiency

- The Role of Hydraulic Pumps in Excavator Efficiency

- How Hydraulic Pumps Convert Power into Motion

- Key performance metrics for pumps

- Types of Excavator Hydraulic Pumps and Their Impact

- Comparison of common pump types

- How Pump Efficiency Affects Excavator Performance

- Productivity and cycle time

- Fuel consumption and operating cost

- Heat generation and component life

- Matching Pump Capacity to Excavator Class

- Typical hydraulic flow ranges

- Maintenance and Best Practices for Long-Term Efficiency

- Essential maintenance steps

- Upgrading and Replacing Excavator Hydraulic Parts

- When to repair vs. replace

- How Quality Parts from SPARKLING MACHINERY Improve Outcomes

- Why OEM-compatible, high-quality parts matter

- Practical Steps Fleet Managers Can Take Today

- Actionable checklist

- Return on Investment: Example Comparison

- Conclusion: Prioritize Excavator Hydraulic Parts for Efficiency

- FAQ

- Q: How often should I inspect or service my excavator hydraulic pump?

- Q: What are common signs of a failing hydraulic pump?

- Q: Can upgrading pump type improve performance?

- Q: Are aftermarket excavator hydraulic parts safe to use?

- Q: How much fuel can I realistically save by improving hydraulic efficiency?

- Q: Where can I source reliable excavator hydraulic parts?

The Role of Hydraulic Pumps in Excavator Efficiency

Hydraulic pumps are the heart of any hydraulic excavator system. Choosing, maintaining, and integrating the right excavator hydraulic parts directly impacts machine productivity, fuel consumption, and long-term operating costs.

How Hydraulic Pumps Convert Power into Motion

Hydraulic pumps convert mechanical energy from the engine into pressurized fluid flow. This pressurized fluid drives actuators (cylinders and motors) that perform digging, swinging, and travel. Because nearly every major function of an excavator depends on hydraulic flow and pressure, pump performance is central to overall machine efficiency.

Key performance metrics for pumps

- Volumetric flow (L/min): how much fluid the pump moves. Different excavator classes require different flow ranges (see section below).

- Working pressure (MPa / psi): how much force the system can generate. Modern excavators commonly operate between 20–35 MPa (≈2,900–5,075 psi).

- Volumetric efficiency (%): how closely real flow approaches theoretical flow, often >90% in well-maintained pumps.

- Mechanical efficiency (%): internal mechanical losses; high-quality pumps often deliver combined efficiencies near 80–90% for new units.

Types of Excavator Hydraulic Pumps and Their Impact

Choosing the correct pump type among common excavator hydraulic parts affects energy efficiency, precision, and cost.

Comparison of common pump types

Below is a concise comparison of typical pump types used in excavators:

| Pump Type | Typical Efficiency | Max Working Pressure (MPa) | Cost & Typical Use |

|---|---|---|---|

| Gear Pump | 80–88% | Up to ~20 MPa | Low cost, simple systems, small machines |

| Vane Pump | 85–90% | Up to ~25 MPa | Better efficiency and smoother flow for mid-range machines |

| Axial Piston Pump | 88–95% | 20–40+ MPa | High performance, variable displacement—common in medium to large excavators |

How Pump Efficiency Affects Excavator Performance

Higher pump efficiency means more of the engine's power is converted to useful hydraulic work instead of being lost to heat and internal leakage. That translates into several measurable benefits for operators and fleet managers.

Productivity and cycle time

Efficient pumps deliver consistent flow and pressure during work cycles (boom, arm, bucket). Better flow control shortens cycle times, increases digging throughput, and improves precision during charging and grading tasks.

Fuel consumption and operating cost

Because hydraulic losses are converted to heat that the engine must overcome, inefficient pumps increase fuel burn. Field and manufacturer reports commonly show that upgrading or properly maintaining hydraulic systems can yield fuel savings in the 5–15% range, depending on machine class and duty cycle. Those savings compound across fleets and long-term operations.

Heat generation and component life

Excessive internal leakage and inefficiencies produce heat. Higher operating temperatures accelerate fluid degradation, seal wear, and component fatigue—shortening the life of other excavator hydraulic parts like valves, hoses, and cylinders. Effective pumps help keep system temperatures in safe ranges and extend component life.

Matching Pump Capacity to Excavator Class

Pump sizing must match the machine's hydraulic demands. Below are typical flow ranges by excavator class to guide selection of excavator hydraulic parts.

Typical hydraulic flow ranges

- Mini excavators: ~40–100 L/min

- Medium excavators: ~100–250 L/min

- Large excavators: ~250–400+ L/min

Using a pump with appropriate flow prevents wasted fuel and reduces stress on valves and actuators. Variable displacement axial piston pumps are common in modern machines because they adjust flow to demand, improving efficiency versus constant-displacement pumps.

Maintenance and Best Practices for Long-Term Efficiency

Regular maintenance of excavator hydraulic parts preserves pump efficiency and prevents costly downtime.

Essential maintenance steps

- Fluid management: Use manufacturer-recommended hydraulic fluids and replace based on contamination levels, not just hours. Clean fluid reduces wear and maintains volumetric efficiency.

- Filtration: Keep filters in spec and replace them at recommended intervals. High-quality filtration prevents abrasive particles from scoring pump components.

- Temperature control: Ensure coolers and radiators are clean and functioning. Excess heat accelerates wear.

- Seal and hose inspection: Replace worn seals and hoses early to prevent leaks and contamination.

- Scheduled diagnostics: Monitor pump flow, pressure, and return-line temperatures. Early detection of reduced volumetric efficiency or increased internal leakage allows planned repairs.

Upgrading and Replacing Excavator Hydraulic Parts

When pumps reach the end of their efficient life, replacement or upgrade decisions should consider total cost of ownership, compatibility, and expected duty cycles.

When to repair vs. replace

Minor internal wear can sometimes be corrected with rebuild kits and component replacement. However, if volumetric efficiency drops significantly, cavitation occurs, or repairs would approach 50% of replacement cost, full replacement with a quality pump is usually the better investment.

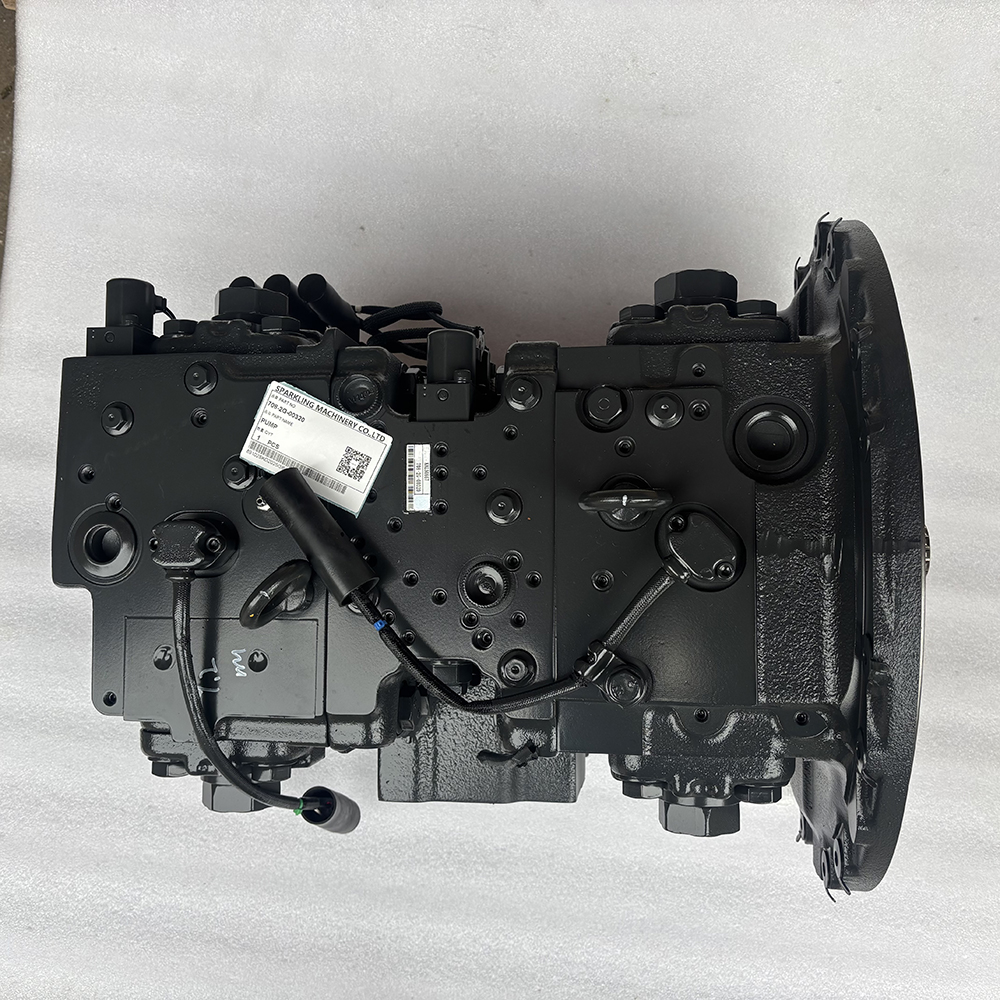

How Quality Parts from SPARKLING MACHINERY Improve Outcomes

SPARKLING MACHINERY, founded in 2013, focuses on high-quality excavator hydraulic parts and components. With an emphasis on stability, precision, and strict quality control, SPARKLING supplies hydraulic pumps and associated parts compatible with top brands such as Caterpillar, Komatsu, Hitachi, and Volvo.

Why OEM-compatible, high-quality parts matter

Using reliable hydraulic components reduces internal losses, maintains pressure control, and lowers the risk of unexpected downtime. SPARKLING MACHINERY provides customized solutions, technical support, and quality-tested parts that help fleets maintain hydraulic efficiency, extend component life, and reduce lifecycle costs.

Practical Steps Fleet Managers Can Take Today

Improving hydraulic system efficiency doesn't always require major investments. Practical measures include:

Actionable checklist

- Implement a fluid analysis program to replace hydraulic fluid based on contamination trends.

- Standardize on high-quality filters and track filter differential pressures.

- Train operators on best practices that reduce peaks in hydraulic demand (e.g., avoiding continuous full-speed hydraulic operation when not necessary).

- Schedule periodic pump performance tests (flow, pressure, and return-line temperature).

- Work with suppliers like SPARKLING MACHINERY to source compatible, high-efficiency pumps and parts.

Return on Investment: Example Comparison

The table below illustrates a simplified example of how pump efficiency and fuel use affect annual operating costs for a mid-size excavator working full days. (Example values are illustrative; fleet-specific results will vary.)

| Scenario | Pump Efficiency | Annual Fuel Use (L) | Estimated Fuel Cost ($) |

|---|---|---|---|

| Baseline (aged pump) | 80% | 12,000 | 15,600 (@ $1.30/L) |

| Upgraded/Maintained pump | 88% | 11,000 | 14,300 (@ $1.30/L) |

In this simplified example, improving pump efficiency reduces annual fuel costs and pays back over time when considering reduced downtime and longer component life.

Conclusion: Prioritize Excavator Hydraulic Parts for Efficiency

Pumps are central to excavator performance. Selecting the right pump type, maintaining hydraulic fluids and filters, and sourcing quality parts from trusted suppliers like SPARKLING MACHINERY directly improves productivity, reduces fuel consumption, and extends component life. For fleet managers and operators focused on minimizing total cost of ownership, hydraulic pump health should be a primary KPI.

FAQ

Q: How often should I inspect or service my excavator hydraulic pump?

A: Inspect hydraulic systems daily for leaks and unusual noises. Perform fluid analysis and filter changes per the manufacturer's schedule or when contamination levels rise. Full pump diagnostics every 1,000–2,000 operating hours is common for mid-size machines.

Q: What are common signs of a failing hydraulic pump?

A: Reduced digging power, slower cycle times, excessive heat in the return line, unusual noises (rattling or whining), and visible leaks are typical signs.

Q: Can upgrading pump type improve performance?

A: Yes. Moving from fixed-displacement to modern variable-displacement axial piston pumps can improve efficiency and control, especially in machines with varying load profiles.

Q: Are aftermarket excavator hydraulic parts safe to use?

A: High-quality aftermarket parts from reputable suppliers can match OEM performance and often offer better value. Ensure the supplier provides compatibility data, testing records, and warranty support—criteria SPARKLING MACHINERY follows.

Q: How much fuel can I realistically save by improving hydraulic efficiency?

A: Depending on the machine and duty cycle, real-world savings commonly fall in the 5–15% range when efficiency is meaningfully improved through maintenance, component upgrades, or system optimization.

Q: Where can I source reliable excavator hydraulic parts?

A: Choose established suppliers with testing and quality controls, documented compatibility with major brands, and technical support. SPARKLING MACHINERY offers a broad range of hydraulic components, undercarriage parts, engine and electrical parts, and accessories compatible with Caterpillar, Komatsu, Hitachi, Volvo, and others.

Lifecycle Cost Analysis: Hydraulic Hose for Volvo Construction Gear

Key Specs to Check on ZGAQ-03591 Hub Replacements

Compatibility Guide: Bearings for R210W-9 and R200W7A

Top 10 Hydraulic Components Essential for Excavator Performance

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

31E3-3187 Accumulator for Hyundai excavators R140W-9 R170W-7 R180W-9 R210W-9 and Case E18C CX37C

The 31E3-3187 Hydraulic Accumulator is a premium diaphragm-type accumulator engineered for Hyundai wheeled excavators (R140W-9/R170W-7/R180W-9/R210W-9) and Case mini-excavators (E18C/CX37C). It stabilizes hydraulic system pressure, absorbs shock waves, and stores energy for peak-demand operations, preventing component fatigue and extending service life in high-vibration construction environments.

Key Features

· OEM-Matched Precision: 0.35L volume, 31.5MPa max working pressure, and diaphragm design for consistent pressure regulation and energy storage.

· High-Strength Construction: Carbon steel body with anti-corrosion coating and reinforced crimped end caps for 10,000+ hours service in harsh conditions.

· Leak-Proof & Shock-Absorbent: Nitrile rubber diaphragm and O-ring seals eliminate fluid leakage; absorbs pressure spikes up to 42MPa to protect valves/pumps.

· Plug-and-Play Fit: Direct bolt-on mounting with 3/4" NPT port; no modification needed for Hyundai/Case excavator installation.

Compatible Equipment

· Excavators: Hyundai R140W-9, R170W-7, R180W-9, R210W-9; Case E18C, CX37C; also fits Hyundai R200W-7, R170W-9.

· Interchangeable Part Numbers: 31E3-3187, 31MN-90680, 31E33187.

Construction Spare Parts VOE14577744 RELIEF VALVE for Volvo Excavators EC330B EC330C EC340D EC360

SPARKLING MACHINERY NEW EC330B EC330C EC340D EC360B EC380D VOE14577744 Relief Valve is a dedicated, high-precision hydraulic component exclusively engineered for VOLVO EC330B, EC330C, EC340D, EC360B, and EC380D crawler excavators—heavy-duty equipment critical for large-scale mining, construction, and infrastructure projects. As a core safety and pressure-regulating part of the excavator’s hydraulic system, it monitors hydraulic pressure in real time and automatically releases excess pressure to prevent overloading of key components like hydraulic pumps, cylinders, and valves. This function is vital for maintaining stable hydraulic operation during high-intensity tasks such as rock breaking, bulk ore loading, and deep excavation, avoiding pressure-surge damage and ensuring uninterrupted workflow.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the genuine part number VOE14577744, the relief valve withstands harsh conditions: high hydraulic pressure (up to 42 MPa), extreme temperature fluctuations (-25°C to 105°C), and continuous heavy-duty vibration. It maintains precise pressure regulation accuracy and resists oil contamination, providing long-lasting reliability for the excavators’ hydraulic systems. Backed by strict performance verification, it guarantees seamless compatibility and operational safety for EC330B/EC330C/EC340D/EC360B/EC380D models.

Rexroth Relief Valve 04950403 R901102333 – 350 Bar Screw‑In Cartridge

The Rexroth Relief Valve 04950403 (part no. R901102333) is a precision-engineered screw-in cartridge valve designed for hydraulic systems in excavators and industrial machinery. This robust, direct-acting spool-type valve offers pressure reducing and relieving capabilities, withstanding up to 350 bar of maximum operating pressure and supporting flow rates around 30 L/min. Constructed with quality materials and standard CAAN cavity compatibility, it ensures responsive, leak-free hydraulic control under demanding conditions.

Premium XKCH-00022 solenoid valve fits Hyundai R125LCR-9A, R145CR9, R160LC9A, and R180LC9S excavators. Reliable hydraulic control part from SPARKLING

The XKCH-00022 Solenoid Valve is a precision-engineered hydraulic control component used in multiple Hyundai crawler excavators, including models R125LCR-9A, R145CR9, R160LC9A, and R180LC9S.

This solenoid valve plays a vital role in directing hydraulic fluid flow in key systems such as travel, swing, or attachment control. Engineered for responsive performance and long-lasting durability, this part ensures accurate actuation and helps maintain overall machine efficiency.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879