Sourcing Reliable Brake Discs for Volvo EW160/EW180 Fleets

- Why brake disc quality matters for wheeled excavators

- Safety and operational risk reduction

- Performance under load: friction, heat, and vibration

- Cost of failure vs. cost of ownership

- Technical specifications and compatibility for Volvo EW160/EW180

- Understanding the VOE14558962 specification

- Key mechanical tolerances to verify

- Material, heat treatment, and corrosion resistance

- How to source and verify reliable brake discs

- Choosing OEM vs. high-quality aftermarket

- Supplier validation checklist

- Incoming inspection and sample testing

- Maintenance, installation, and performance testing

- Best practices for installation

- Routine inspection schedule and indicators

- Testing procedures after replacement

- Comparing SPARKLING MACHINERY VOE14558962 to common alternatives

- Procurement strategy and fleet-level considerations

- Batch procurement, storage, and shelf life

- Spare parts planning and interchangeability

- Documentation and change control

- Brand advantages: why consider SPARKLING MACHINERY for VOE14558962

- Reliability and testing

- Cost-effectiveness and after-sales support

- FAQ — Common questions about brake discs for Volvo EW160/EW180

- Q: Is it safe to use aftermarket brake discs instead of Volvo OEM parts?

- Q: How often should brake discs be inspected on EW160/EW180 machines?

- Q: What are the signs a brake disc needs replacement?

- Q: Can a corroded disc be cleaned and reused?

- Q: How does temperature range (-30°C to 90°C) affect brake disc performance?

- Authoritative references

- Contact and product links

Fleet managers and procurement specialists responsible for Volvo EW160 and EW180 wheeled excavators need clear, actionable guidance when sourcing brake discs. This article explains technical compatibility, inspection and testing criteria, supply chain validation, and installation considerations for brake disc replacement—focusing on the VOE14558962 specification and the disc brake principles that determine safety and performance on road and jobsite conditions.

Even with dependable suppliers, regular upkeep is essential, which is why following an inspection checklist for Volvo excavator disc brakes is recommended.

Why brake disc quality matters for wheeled excavators

Safety and operational risk reduction

Brake discs (also called disc rotors or brake rotors) are a primary safety component for wheeled excavators used in road construction, municipal engineering, and material handling. A disc with inadequate material quality, poor thermal capacity, or excessive runout increases stopping distance and raises the risk of skid, tip-over, or load-shift incidents during maneuvering or loading. For Volvo EW160/EW180 fleets, choosing the correct brake disc is a direct intervention to reduce operational risk and regulatory exposure.

Performance under load: friction, heat, and vibration

Excavator braking combines high friction and repeated thermal cycling. A brake disc must maintain friction coefficient, dissipate heat rapidly, and resist thermal crack formation. Important performance metrics include thermal capacity (ability to absorb and dissipate heat), wear resistance of the friction surface, and vibration damping to avoid squeal and excessive pad wear. ISO and industry guidance (see SAE International) explain how these metrics affect brake life and consistency.

Cost of failure vs. cost of ownership

Replacing a failed brake disc, or dealing with unscheduled downtime caused by poor braking performance, has direct costs (parts and labor) and indirect costs (delays, penalties, safety investigations). Investing in discs that meet or exceed OEM standards reduces total cost of ownership by extending service intervals and maintaining predictable braking performance.

Technical specifications and compatibility for Volvo EW160/EW180

Understanding the VOE14558962 specification

The OEM part number VOE14558962 indicates Volvo's design, dimensional tolerances, and material choices for EW160C/D/E and EW180C/D wheeled excavators. When sourcing, verify: exact diameter, thickness, bolt pattern and pitch circle diameter (PCD), ventilation (solid vs. vented), and any machined mating surfaces. The correct rotor ensures correct pad contact, caliper alignment, and consistent hydraulic performance.

Key mechanical tolerances to verify

Important tolerances include lateral runout, axial runout, and parallelism across the braking surface. Excessive runout (>0.05–0.10 mm depending on OEM threshold) leads to pulsation and uneven pad wear. Confirm tolerances against Volvo specifications or trusted cross-reference documentation and use calibrated measurement tools during incoming inspection.

Material, heat treatment, and corrosion resistance

Brake discs must balance hardness and toughness. Typical materials are high-grade cast iron or nodular iron (ductile iron) with specific heat treatment to resist cracking. Surface coatings or specialized paint systems improve corrosion resistance for machines working in corrosive environments. Confirm metallurgical certificates or material test reports for each batch when possible.

How to source and verify reliable brake discs

Choosing OEM vs. high-quality aftermarket

OEM parts (Volvo-branded) are the default option for guaranteed fit and spec compliance. However, qualified aftermarket manufacturers can offer cost-effective alternatives when they meet VOE14558962 dimensions and pass equivalent testing. The product VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 DISC BRAKE SPARKLING MACHINERY provides an example of an aftermarket item manufactured to Volvo OEM standards with dedicated testing for performance and compatibility.

SPARKLING MACHINERY NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 Disc Brake is a dedicated safety component for VOLVO EW160C/EW160D/EW160E/EW180C/EW180D wheeled excavators (used in road construction, municipal engineering, and material handling). As the core of the braking system, it provides stable stopping force to ensure safe on-road travel and off-road operation, preventing accidents during tasks like loading or navigating uneven terrain.

Meeting VOLVO OEM standards (part no. VOE14558962), it endures high friction, -30°C to 90°C temperatures, and vibration. It resists wear and corrosion, ensuring long-term braking reliability for the five VOLVO models, with strict testing guaranteeing compatibility and safe performance.

Supplier validation checklist

- Request full dimensional drawings and verify against vehicle service manual.

- Ask for material certificates, heat-treatment records, and batch inspection reports.

- Confirm testing: thermal cycling, friction coefficient testing, vibration testing, corrosion testing (salt spray).

- Check traceability and serial/batch coding for warranty and recall handling.

- Review third-party lab test reports or independent endorsements where available.

Incoming inspection and sample testing

Even with certified suppliers, an incoming inspection process is essential. Key checks include dimensional verification, flatness/runout measurement, visual surface inspection for casting defects or cracks, coating adhesion tests for corrosion-resistant finishes, and initial fitment trials on a sample machine. For high-value fleets, consider laboratory friction testing to confirm brake torque characteristics prior to full batch installation.

Maintenance, installation, and performance testing

Best practices for installation

Proper installation prevents premature failures: torque caliper and wheel bolts to manufacturer values, ensure clean mating surfaces, remove any protective coatings from friction contact areas if specified, and verify caliper alignment before final assembly. Use calibrated torque wrenches and reference the Volvo service manual for specific sequences and values.

Routine inspection schedule and indicators

Set inspection intervals based on hours of operation, working environment, and duty cycle. Typical checks every 250–500 hours include visual wear assessment, measurement of disc thickness vs. minimum allowable thickness, pad wear monitoring, and checking for thermal cracks or heat spots. Listen for squeal or abnormal vibration—early indicators of rotor runout or pad glazing.

Testing procedures after replacement

After replacement, perform a staged brake test: low-speed functional check, incremental load testing, and full-performance stop tests under controlled conditions to validate stopping distance and pedal feel. Record results and compare them to baseline values to ensure consistent braking torque. Keep records for warranty and safety audits.

Comparing SPARKLING MACHINERY VOE14558962 to common alternatives

The table below summarizes common purchase considerations when comparing OEM Volvo discs, SPARKLING MACHINERY parts made to VOE14558962, and generic aftermarket rotors.

| Aspect | Volvo OEM | SPARKLING MACHINERY VOE14558962 | Generic Aftermarket |

|---|---|---|---|

| Fit & Dimensions | Guaranteed to spec | Manufactured to VOE14558962 tolerances | Varies; requires verification |

| Material & Heat Treatment | OEM-specified alloys and processes | Certified material reports provided | Often unspecified |

| Testing (thermal/corrosion) | OEM tests per Volvo standards | Third-party and in-house testing claimed | Limited or absent |

| Warranty & Traceability | Full OEM warranty | Batch traceability and warranty | Variable |

| Price | Highest | Competitive, cost-effective | Lowest (risk of hidden costs) |

Procurement strategy and fleet-level considerations

Batch procurement, storage, and shelf life

Procure in batches that match your fleet’s maintenance cycles to avoid long-term storage risks. Store brake discs in dry, covered environments, free from corrosive chemicals and extreme temperature fluctuations. Protective coatings can delay corrosion, but long-term storage still requires periodic inspection before installation.

Spare parts planning and interchangeability

Maintain a bill of parts cross-reference for your EW160/EW180 models and track which parts are interchangeable across C/D/E variants. Having one reliable common SKU like VOE14558962 simplifies inventory and reduces the risk of wrong-part installation. Keep a small buffer stock of discs and pads to minimize downtime.

Documentation and change control

Document every replacement: supplier, batch number, measured runout/thickness pre-installation, installation technician, and test results. For fleets under regulatory scrutiny or for those working on municipal projects, documented change control demonstrates due diligence and traceability.

Brand advantages: why consider SPARKLING MACHINERY for VOE14558962

SPARKLING MACHINERY positions its VOE14558962 disc brake as a parts solution specifically engineered for Volvo EW160 and EW180 wheeled excavators. Key advantages include: strict adherence to Volvo OEM dimensional specifications, material certification for high friction and thermal resistance, salt-spray and vibration testing to ensure durability in municipal and road construction environments, and batch traceability for warranty and compliance. These attributes make it a competitive choice for fleet managers seeking OEM-level performance at a more favorable cost.

Reliability and testing

By providing detailed testing reports and batch traceability, SPARKLING MACHINERY offers procurement certainty. Their focus on thermal cycling and wear testing reduces the probability of early failure and uneven pad wear.

Cost-effectiveness and after-sales support

Compared with OEM list prices, a qualified aftermarket supplier like SPARKLING MACHINERY can reduce per-unit cost while maintaining performance. Ensure the supplier provides clear warranty terms, installation assistance, and responsive parts support for long-term fleet sustainability.

FAQ — Common questions about brake discs for Volvo EW160/EW180

Q: Is it safe to use aftermarket brake discs instead of Volvo OEM parts?

A: Yes, provided the aftermarket disc is manufactured to the VOE14558962 specification and accompanied by material certificates, dimensional data, and independent test results. Validate supplier traceability, warranty, and third-party testing before adoption.

Q: How often should brake discs be inspected on EW160/EW180 machines?

A: Inspect discs every 250–500 operating hours or sooner in heavy-duty or high-cycling conditions. Key checks include thickness vs. minimum allowable thickness, visual cracks, heat spots, and runout measurements.

Q: What are the signs a brake disc needs replacement?

A: Common signs include reduced braking performance, pedal pulsation, unusual vibration or squeal, visible thermal cracking or warping, and disc thickness below the minimum specified limit.

Q: Can a corroded disc be cleaned and reused?

A: Light surface rust can often be removed and the disc reused if thickness and structural integrity are intact. Deep pitting or corrosion compromising thickness or surface flatness requires replacement.

Q: How does temperature range (-30°C to 90°C) affect brake disc performance?

A: Discs and friction materials must maintain performance across this range. Cold conditions can change pad friction characteristics and increase the risk of cracking under sudden high thermal loads, while high ambient temperatures reduce cooling capacity. Materials and coatings designed for this range improve consistent stopping performance.

Authoritative references

- Disc brake — Wikipedia

- SAE International — industry standards and research

- Volvo Construction Equipment — official site

Contact and product links

If you would like to evaluate or order the part: View VOLVO EXCAVATOR PARTS VOE14558962 Disc Brake or contact our sales team for technical datasheets, batch test reports, and volume pricing. For immediate assistance, email sales@sparkling-machinery.com or call +86-XXX-XXXXXXX (region-specific support available).

Contact our parts specialists to request a sample inspection kit or to schedule a fleet compatibility audit. Quick response ensures minimum downtime and verified fitment for your EW160/EW180 machines.

How Hyundai R170W7 Parts Improve Machine Performance

Top Signs Your Excavator Needs a Hub Replacement

Field Replacement Steps for K9003219 on DL450 Loaders

Choosing the Right Hydraulic Oil for Your Excavator: Tips and Recommendations

faq

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

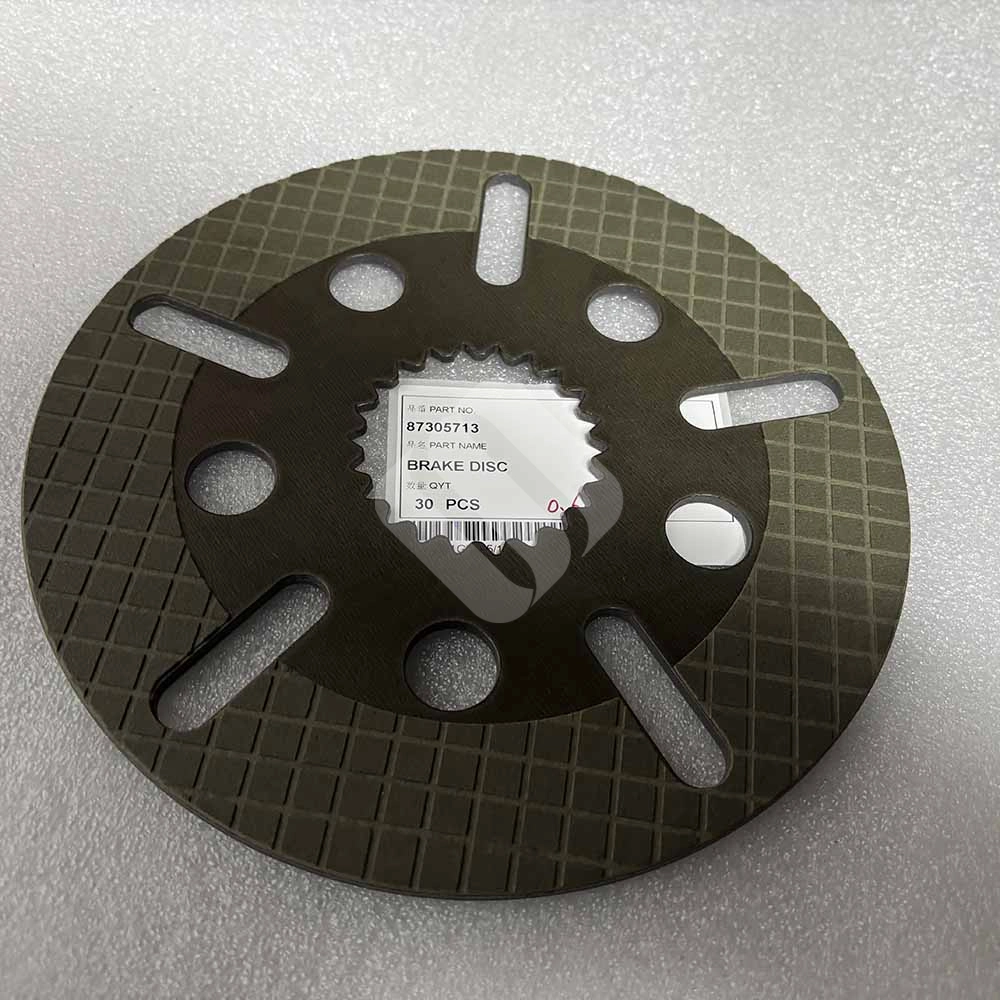

VOLVO HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B110B B100B LB90.B B90B B95B 87305713 BRAKE DISC SPARKLING MACHINERY

SPARKLING MACHINERY NEW B110B B100B LB90.B B90B B95B 87305713 Brake Disc is a core braking component for Volvo B110B/B100B/LB90.B/B90B/B95B excavators (heavy-duty construction/mining use). It works with brake pads to generate friction, ensuring reliable stopping and operational safety.

Meeting Volvo OEM standards (87305713), it resists -30°C to 300°C temps, wear, and thermal deformation, ensuring seamless compatibility and long-term reliable braking performance.

New Holland Backhoe Loaders 87305713 83959970 47123297 Brake Disc

87305713 is a specific industrial part number for a Brake Disc (or Friction Plate) used in agricultural and construction machinery, primarily manufactured by New Holland.

1.This friction disc is designed for oil-immersed (wet) braking systems. It is commonly found in:

New Holland Backhoe Loaders: Models including B90B, B100B, B110B, B115B, LB75, LB90, LB110, and LB115.

Ford Tractors: Series 550, 555, and 655.

Case IH: Certain models sharing the same drivetrain components

2. Technical Specifications

Outside Diameter (OD): ~204.75 mm

Inside Diameter (ID): ~55.88 mm (spline area)

Thickness: 4.8 mm

Teeth Count: 22 Teeth

Material: Paper-based friction material with a waffle-groove pattern for oil circulation and cooling

3. Cross-Reference Numbers

This part is often interchangeable with the following OEM and aftermarket numbers:

CNH: 83959970, 47123297

Ford/NH Original: E6NN2A097BB

Hyundai Wheel Loaders HL730-9 HL730-9A HL730-9S ZGAQ-03450 0501.323.355 DISC-INNER CLUTCH CHINA MADE

Part numbers 0501.323.355 (a ZF part number) and ZGAQ-03450 (a Hyundai part number) both refer to a Friction Disc used in the brake or clutch assembly of heavy machinery transmissions and axles.

This component is an inner clutch or brake friction plate/disc. It is a critical wear item within the drivetrain assembly (likely a ZF axle or transmission) responsible for creating the necessary friction to engage clutches or apply brakes in heavy equipment.

Compatible Equipment

This friction disc is commonly used in Hyundai wheel loaders and other construction equipment that utilize compatible ZF axles:

Hyundai Wheel Loaders: HL730-9, HL730-9A, HL730-9S, HL730TM-9A.

Other Compatible Equipment: Various backhoe loaders, including certain models by John Deere (e.g., 310, 315, 210K, 310SJ, 325K)

Part Numbers: 0501.323.355, 0501323355, ZGAQ-03450, ZGAQ03450, AT339543, 482-6743, VOE 15071853, S06/42932

ZTAM-00615 Support Kit Compatible with Hyundai R140W-7 & R140W-7A Wheel Excavators

ZTAM-00615 is an OEM-compatible support kit for Hyundai R140W-7/R140W-7A excavators. It provides essential structural reinforcement and vibration damping for key components, ensuring reliable performance under heavy loads and harsh working conditions in construction and engineering applications.

Key Features

· OEM direct‑fit design: Exact matching of mounting positions, hole spacing, and geometric dimensions for Hyundai R140W‑7 / R140W‑7A — plug‑and‑play without modification.

· High‑strength structural support: Heavy‑duty steel construction with reinforced stress points for excellent load capacity and impact resistance.

· Stable & durable: Anti‑wear, anti‑deformation, and anti‑corrosion surface treatment for long service life in harsh environments.

Compatible Models: Hyundai Wheel Excavators R140W-7, R140W-7A

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879