The Definitive Guide to Excavator Diesel Engine Turbochargers: Maximizing Power with High-Performance Forced-Induction Core Components

This expert guide explores why a diesel engine turbocharger is the high-performance forced-induction core component essential for efficiency. Learn how the Top 15 Excavator Parts Manufacturers optimize the key parts of an excavator to maximize power, reduce downtime, and lower TCO.

- Introduction

- Supercharge vs Turbocharge

- Technical Comparison: OEM vs. Aftermarket High-Performance Units

- Inside the Component: A Turbocharger Diagram Overview

- Procurement Strategy: Turbocharger Price vs Value

- Performance Mapping: From Small Turbocharger to Compound Systems

- Diagnostic Matrix: Utilizing the Turbocharger Diagram

- Making the Final Call on Turbocharger Price

- Maintenance and Turbocharger Repair

- Why Quality Trumps Initial Cost

- Conclusion

- Frequently Asked Questions (FAQs)

- What is the average turbocharger price for a 20-ton excavator?

- Can I perform a turbocharger repair in the field?

- Why choose a variable geometry turbocharger over a standard one?

- How do I find a reliable diesel turbocharger supplier?

- Is an electric turbocharger worth the investment?

Introduction

In the high-stakes world of earthmoving and heavy construction, downtime is the silent profit killer. For fleet managers and procurement specialists, the diesel engine turbocharger is not merely an add-on; it is the high-performance forced-induction core component that dictates whether your machine delivers peak breakout force or becomes a fuel-guzzling liability.

To maintain a competitive edge, many global buyers look toward the Top 15 Excavator Parts Manufacturers to ensure their supply chain remains robust. This guide dives deep into the technology, selection, and maintenance of one of the key parts of an excavator to help you minimize TCO (Total Cost of Ownership).

Supercharge vs Turbocharge

In the realm of heavy-duty machinery, the debate of supercharge vs turbocharge is often settled by efficiency. While a supercharger is driven mechanically by the engine's crankshaft, a diesel engine turbocharger utilizes "free" energy from exhaust gases. For excavators, the turbocharger is the superior choice because it doesn't parasitic drain engine power, which is critical when every kilowatt is needed for hydraulic flow.

Whether you are running a small turbocharger on a compact mini-excavator or a big turbocharger on a 50-ton mining beast, the goal remains the same: forcing more oxygen into the combustion chamber to burn fuel more effectively.

Technical Comparison: OEM vs. Aftermarket High-Performance Units

When sourcing from the best excavator parts manufacturers, it’s essential to understand what separates a premium high-performance forced-induction core component from a standard replacement.

| Feature | Standard Replacement | High-Performance Component |

| Turbine Material | Basic Cast Iron/Alloy | Inconel 713C / Titanium Aluminum |

| Balancing Standard | Basic Static Balance | VSR High-Speed Dynamic Balancing |

| Thrust Bearing | 270° Copper Bearing | 360° Reinforced Steel/Ceramic |

| Heat Resistance | Up to 650°C | Up to 950°C+ |

| Response Time | Standard Lag | Reduced Turbo Lag (Optimized A/R) |

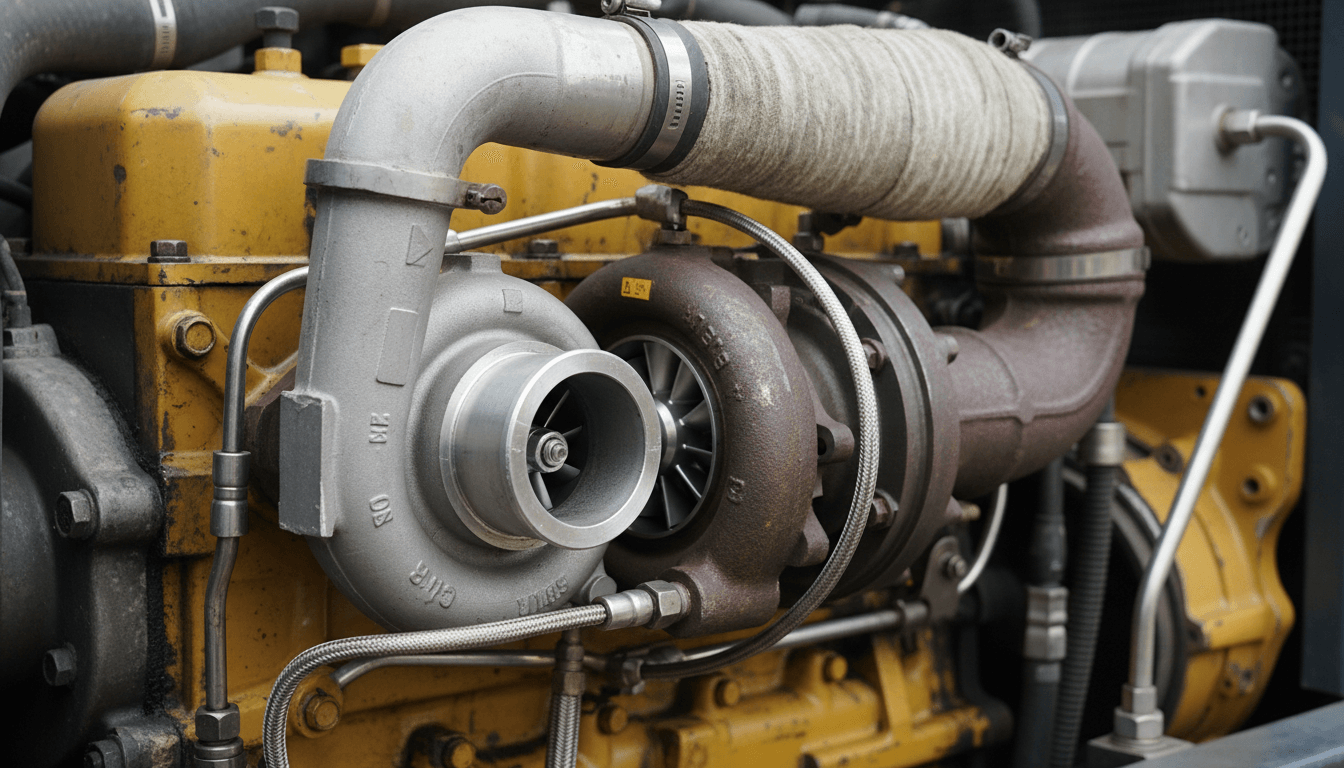

Inside the Component: A Turbocharger Diagram Overview

To appreciate the complexity of a diesel turbocharger, one must understand its internal architecture. A standard turbocharger diagram typically illustrates two main sides: the turbine (hot side) and the compressor (cold side), connected by a common shaft.

-

The Turbine Housing: Crafted from high-nickel cast iron to withstand extreme thermal cycling.

-

The Compressor Wheel: Often forged from aerospace-grade aluminum to reduce rotational inertia.

-

The Bearing Housing: The heart of the unit, requiring a constant flow of filtered oil to support the shaft spinning at over 100,000 RPM.

Procurement Strategy: Turbocharger Price vs Value

When searching for a turbocharger price online, the range can be staggering. However, as a marketing director in this industry for a decade, I warn against "price-only" procurement. A low-cost unit often skips the critical VSR (Vibration Sorting Rig) balancing process, leading to premature bearing failure.

When sourcing a diesel turbocharger, consider the following "Value Checklist":

-

Material Grade: Does it use Inconel 713C for the turbine?

-

Balancing Standards: Is it balanced to G0.4 or better?

-

Warranty: Does the manufacturer back the product for at least 12 months of heavy-duty use?

-

Performance Mapping: From Small Turbocharger to Compound Systems

In the procurement process, understanding the "Boost Profile" is essential for matching the component to your specific application. A small turbocharger is engineered for rapid spool-up, making it ideal for mini-excavators performing precision utility work. Conversely, a big turbocharger is designed to move massive volumes of air for heavy-duty mining, though it may sacrifice some low-end responsiveness.

For Tier 4 Final engines, we often see the integration of a variable geometry turbocharger (VGT). By adjusting the internal vane angles, this unit mimics the characteristics of both a small turbocharger at low RPM and a big turbocharger at high RPM. For the most demanding environments, compound turbochargers are utilized, where two units work in series to provide a massive, linear power band.

Diagnostic Matrix: Utilizing the Turbocharger Diagram

When a technician references a turbocharger diagram during a routine inspection, they are looking for specific flow paths and seal locations. Understanding these visuals is critical for an accurate turbocharger repair assessment. Below is a quick diagnostic guide for the powertrain:

-

Excessive Oil in the Intake: Refer to your turbocharger diagram to check the compressor-side seals. This is often a sign of oil pressure irregularities rather than a part defect.

-

Whining Sound: This "siren" noise usually indicates a wheel imbalance. If not addressed via turbocharger repair or replacement, it can lead to a catastrophic shaft snap.

-

Slow Boost Response: In a variable geometry turbocharger, this often indicates that the internal vanes are "carboned up" or the actuator has failed.

Making the Final Call on Turbocharger Price

Ultimately, the turbocharger price you pay should be viewed as an investment in machine uptime. Whether you are sourcing a standard diesel turbocharger or a specialized electric turbocharger, the cost of the part is always lower than the cost of a week-long site stoppage. By selecting high-performance units from the Top 15 Excavator Parts Manufacturers, you are choosing components that have been tested against the most rigorous "surge" and "choke" limits on the compressor map.

-

Maintenance and Turbocharger Repair

Even the most robust high-performance forced-induction core component requires care. A successful turbocharger repair is only possible if the housings are intact. Common maintenance triggers include:

-

Oil Contamination: The most frequent cause of shaft scoring.

-

Foreign Object Damage: Ensure air filters are changed regularly; a single pebble can destroy a compressor wheel.

-

Heat Soak: Never shut down a hot engine immediately; let it idle to prevent oil coking inside the bearing housing.

Why Quality Trumps Initial Cost

While "budget" options are tempting, the Total Cost of Ownership (TCO) usually tells a different story. Leading firms featured in the best excavator parts manufacturers lists maintain their reputation because their parts prevent catastrophic engine failures. A failed turbocharger can send shrapnel into the intercooler or, worse, the combustion chamber, leading to an engine rebuild that costs ten times the price of the part itself.

Conclusion

The diesel engine turbocharger remains the most effective way to balance power, emissions, and fuel economy. By understanding the nuances of variable geometry turbocharger technology or the benefits of compound turbochargers, you can make better-informed decisions for your fleet. Whether you are looking for a small turbocharger or a big turbocharger, always prioritize quality from reputable manufacturers to ensure your project stays on schedule.

Frequently Asked Questions (FAQs)

What is the average turbocharger price for a 20-ton excavator?

While prices vary by brand and technology (e.g., VGT vs. fixed), a high-quality aftermarket unit typically ranges from $500 to $1,500, whereas OEM units can exceed $3,000.

Can I perform a turbocharger repair in the field?

Minor issues like gasket replacement can be done in the field, but internal repairs involving the shaft or wheels require a clean-room environment and high-speed balancing equipment.

Why choose a variable geometry turbocharger over a standard one?

A VGT provides better fuel economy and significantly faster hydraulic response, though it requires more precise electronic control and maintenance.

How do I find a reliable diesel turbocharger supplier?

Start by researching the top 15 excavator parts manufacturers. Look for those with ISO certifications and a proven track record in mining and heavy construction.

Is an electric turbocharger worth the investment?

For most standard excavation tasks, a traditional exhaust-driven unit is sufficient. Electric turbocharger technology is currently best suited for high-performance applications where zero-lag response is a mission-critical requirement.

The Meaning of the Warning Lights on Kubota Excavators

Fixing Oil Cooler Leaks in Heavy Machinery: A Complete Guide

Engine Oil Leak Repair Costs: A Comprehensive Guide

Hyundai & Doosan Wheel Excavator Parts Supplier | Complete Range of Replacement Components

Kubota Error Codes: A Comprehensive Diagnostic & Reset Manual

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

31Y1-14050 Hydraulic Seal Kit Compatible with Hyundai Wheel Excavators R140W-7 R140W-7A R130W-3 R170W-3 | Cylinder Repair Seal Kit

31Y1-14050 Hydraulic Seal Kit Compatible with Hyundai Wheel Excavators R140W-7 R140W-7A R130W-3 R170W-3 | Cylinder Repair Seal Kit

31EM-00545 Seal Kit Compatible with Hyundai Wheel Excavators R140W-7 R140W-7A R140W-9 R170W-9 HW140 | Hydraulic Repair Seal Kit

31EM-00545 Seal Kit Compatible with Hyundai Wheel Excavators R140W-7 R140W-7A R140W-9 R170W-9 HW140 | Hydraulic Repair Seal Kit

21Q4-60212 Rear Lamp RH Compatible with Hyundai Wheel Excavators R140W-9 R140W-9A R190W-9 R210W-9 | Right Rear Tail Light Assembly

21Q4-60212 Rear Lamp RH Compatible with Hyundai Wheel Excavators R140W-9 R140W-9A R190W-9 R210W-9 | Right Rear Tail Light Assembly

21Q4-60201 Rear Combination Lamp LH Compatible with Hyundai Wheel Excavators R140W-9 R140W-9A R180W-9A R210W-9 | Left Rear Combi Tail Light Assembly

21Q4-60201 Rear Combination Lamp LH Compatible with Hyundai Wheel Excavators R140W-9 R140W-9A R180W-9A R210W-9 | Left Rear Combi Tail Light Assembly

21Q4-10360 RH Lamp Compatible with Hyundai Wheel Excavators R140W-9 R170W-9S HW140 HW160 HW180 | Right Side Work Light Assembly

21Q4-10360 RH Lamp Compatible with Hyundai Wheel Excavators R140W-9 R170W-9S HW140 HW160 HW180 | Right Side Work Light Assembly

21Q4-10350 LH Lamp Compatible with Hyundai Wheel Excavators HW140 HW160 HW180 HW210 | Left Side Work Light Assembly

21Q4-10350 LH Lamp Compatible with Hyundai Wheel Excavators HW140 HW160 HW180 HW210 | Left Side Work Light Assembly

24V Monitor 21N8-30013 Compatible with Hyundai Excavators R110-7 R140LC-7 R140W-7 R170W-7 R200W-7 | Instrument Display Panel for Construction Equipmen

24V Monitor 21N8-30013 Compatible with Hyundai Excavators R110-7 R140LC-7 R140W-7 R170W-7 R200W-7 | Instrument Display Panel for Construction Equipmen

24V Wiper Motor with Bracket 21N6-01280 21N6-01260 Compatible with Hyundai Excavators R110-7 R140LC-7 R160LC-7 R140W-7 R160LC-9 | Windshield Wiper Mot

24V Wiper Motor with Bracket 21N6-01280 21N6-01260 Compatible with Hyundai Excavators R110-7 R140LC-7 R160LC-7 R140W-7 R160LC-9 | Windshield Wiper Mot

24V Air Conditioner Controller 11Q6-90030 Compatible with Hyundai Excavators R1200-9 R140LC-9 R160LC-9 R140W-9 R170W-9 | HVAC Climate Control Panel fo

24V Air Conditioner Controller 11Q6-90030 Compatible with Hyundai Excavators R1200-9 R140LC-9 R160LC-9 R140W-9 R170W-9 | HVAC Climate Control Panel fo

ZTAM-00615 Support Kit Compatible with Hyundai R140W-7 & R140W-7A Wheel Excavators

ZTAM-00615 Support Kit Compatible with Hyundai R140W-7 & R140W-7A Wheel ExcavatorsGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879