The Ultimate Guide to Excavator Parts: Anatomy, Functionality & Future Trends for 2026

A comprehensive guide to excavator parts, covering anatomy, functionality, maintenance, and future trends like electrification and predictive diagnostics for 2026.

- What are the Essential Excavator Parts and Their Core Functions?

- Core System Divisions

- Key Takeaways: Quick Overview of Excavator Parts

- The Undercarriage: Foundation of Mobility and Stability

- Critical Components

- The Superstructure (House): Powerhouse and Control Center

- Key Assembly Units

- The Workgroup: Precision Digging and Lifting

- Attachment Breakdown

- Essential Wear Parts: Maximizing Lifespan and Performance

- Common Wear Items

- Expert Tips for Excavator Part Maintenance and Longevity

- Actionable Maintenance Schedule

- Advanced Diagnostics: Leveraging Technology for Predictive Maintenance

- Tech Tools

- Sourcing Excavator Parts: OEM vs. Aftermarket & Cost Considerations

- Sourcing Guide

- Future Trends in Excavator Parts: Innovation for 2026 and Beyond

- 2026 Outlook

- Conclusion

- Frequently Asked Questions (FAQ)

- What are the three main sections of an excavator?

- What is the most important part of an excavator?

- How often should excavator parts be replaced?

- What is the difference between OEM and aftermarket excavator parts?

- What role does the counterweight play in an excavator?

- How does the hydraulic system work in an excavator?

- What are ground engaging tools (GET)?

- Can I use parts from different excavator brands?

- References

What are the Essential Excavator Parts and Their Core Functions?

Excavator parts are the specialized components that allow heavy machinery to execute digging, lifting, and demolition operations with precision. The three primary systems are the undercarriage (mobility), the superstructure (power), and the workgroup (digging), all driven by a complex hydraulic network.

Understanding the distinct functions of these parts of an excavator is critical for minimizing downtime. Whether you are managing a fleet of mini excavator parts or sourcing heavy-duty replacements, knowing how components like the hydraulic pump, boom, and track system interact ensures your machine operates at peak efficiency. Ignorance here leads to costly repairs; for instance, neglecting undercarriage tension can accelerate wear by 50%.

Core System Divisions

· Undercarriage: The foundation providing stability and movement.

· Superstructure (House): Contains the engine, cab, and main hydraulic pumps.

· Workgroup: The boom, arm, and bucket that engage with the material.

Key Takeaways: Quick Overview of Excavator Parts

Excavators are complex systems where mechanical, hydraulic, and electronic components must synchronize perfectly. Regular maintenance of these excavator spare parts significantly extends machine life.

· Three Main Divisions: Machines consist of the Undercarriage, Superstructure, and Workgroup.

· Hydraulic Dominance: The hydraulic system is the machine's heartbeat, powering the drive axle assembly (in wheeled models) and digging arms.

· Maintenance ROI: Proactive care of parts of excavator systems reduces total cost of ownership.

· Future Proofing: The industry is shifting toward electrification and smart diagnostics.

The Undercarriage: Foundation of Mobility and Stability

The undercarriage is the chassis of the excavator, housing the track system or wheels to provide traction and support the machine's immense weight. It absorbs the stress of operation and is often the most expensive system to repair, accounting for up to 50% of maintenance costs.

For crawler excavators, this system is a complex loop of moving parts. For wheeled excavators, the drive axle assembly and power transmission components replace tracks to allow for road travel. Sourcing high-quality excavator undercarriage parts is non-negotiable for durability.

Critical Components

1. Track Chains & Shoes: Steel or rubber pads that make contact with the ground.

2. Rollers (Top & Bottom): Support the machine's weight and guide the chain.

3. Idlers: Maintain track tension to prevent slippage (de-tracking).

4. Sprockets: Engage the track links to propel the machine.

5. Final Drives: Hydraulic motors that provide the torque for movement.

The Superstructure (House): Powerhouse and Control Center

The superstructure, or "house," is the rotating upper assembly that sits atop the undercarriage and contains the engine, hydraulic pumps, and operator cab. It connects to the lower unit via a slew ring, allowing for continuous 360-degree rotation.

This section houses the critical power transmission components (hydraulic pumps and motors) that convert engine power into fluid pressure. When looking for excavator parts for sale, the condition of the superstructure's internal components is a primary value indicator.

Key Assembly Units

· Operator Cab: Features ROPS (Roll-Over Protective Structures) and ergonomic controls.

· Engine: The prime mover, usually a diesel unit, driving the hydraulic pumps.

· Counterweight: Heavy metal mass at the rear to prevent tipping during heavy lifts.

· Hydraulic Tank: Reservoir for fluid, critical for cooling and lubrication.

· Swing Drive: Motor and gearbox enabling the house to rotate.

The Workgroup: Precision Digging and Lifting

The workgroup consists of the boom, arm (or stick), and bucket, connected by pins and bushings to perform the actual excavation work. This linkage system relies on powerful hydraulic cylinders to extend, retract, and curl, giving the operator precise control over the payload.

Depending on the application, you might swap standard parts of an excavator workgroup for specialized tools. For example, a mini excavator might use an auger or breaker instead of a bucket.

Attachment Breakdown

· Boom: The main lifting arm attached to the superstructure (Mono or 2-piece).

· Arm/Stick: Connects the boom to the bucket, determining digging depth.

· Bucket: The ground-engaging tool (GET) available in digging, grading, or trenching profiles.

· Cylinders: Hydraulic actuators that push and pull the boom, arm, and bucket.

· Linkage (H-Link): Provides the leverage necessary for bucket curling force.

Essential Wear Parts: Maximizing Lifespan and Performance

Wear parts are sacrificial components designed to absorb abrasion and impact, protecting the machine's permanent structures from damage. Proactive replacement of these excavator spare parts prevents catastrophic failure of more expensive assemblies.

For example, running a bucket with worn teeth increases fuel consumption and strains the hydraulic system. You can learn more about sourcing these components in our guide on Excavator Parts Manufacturers.

Common Wear Items

1. Ground Engaging Tools (GET): Teeth, adapters, and side cutters on the bucket.

2. Undercarriage Wear: Sprockets, rollers, and track links wear down over time.

3. Filters: Air, fuel, and hydraulic filters must be changed to prevent contamination.

4. Pins & Bushings: These pivot points wear out due to friction and require regular greasing.

Expert Tips for Excavator Part Maintenance and Longevity

Effective maintenance is a disciplined routine of inspection, lubrication, and scheduled replacement to ensure machine availability. "Run-to-failure" is not a strategy; it is a financial liability.

Operators should perform a "walk-around" inspection daily. A deep understanding of Key Parts of an Excavator and Their Functions helps operators spot issues before they escalate.

Actionable Maintenance Schedule

· Daily: Check fluid levels (hydraulic, engine oil, coolant) and grease all pivot points.

· Weekly: Inspect excavator undercarriage parts for track tension and loose bolts.

· Monthly: Analyze oil samples for metal particles (indicating internal wear).

· Seasonally: Replace filters and check hydraulic hoses for cracking or leaks.

Advanced Diagnostics: Leveraging Technology for Predictive Maintenance

Predictive maintenance utilizes telematics and IoT sensors to monitor machine health in real-time, predicting failures before they occur. According to 2024 industry reports, predictive strategies can reduce downtime by 35-50% and maintenance costs by up to 30%.

Modern excavator parts are increasingly "smart." Sensors embedded in the hydraulic system can detect pressure spikes or temperature anomalies, alerting fleet managers via dashboard software.

Tech Tools

· Telematics: GPS and performance data (idle time, fuel burn).

· Oil Analysis: Detecting microscopic wear metals.

· Thermal Imaging: Identifying overheating pumps or bearings.

· Vibration Sensors: Monitoring the health of drive axle assembly bearings.

Sourcing Excavator Parts: OEM vs. Aftermarket & Cost Considerations

Choosing between OEM (Original Equipment Manufacturer) and aftermarket parts involves balancing upfront costs against guaranteed fitment and warranty. While OEM parts ensure factory specifications, high-quality aftermarket excavator parts for sale can offer significant savings without compromising performance.

Global statistics indicate the construction equipment spare parts market is valued at over $31 billion in 2025. This massive market means buyers have more choices than ever.

Sourcing Guide

1. OEM: Best for critical internal engine or hydraulic components. Higher cost, higher security.

2. Aftermarket: Ideal for wear parts (teeth, tracks) and undercarriage. Variable quality; vet suppliers carefully.

3. Rebuilt/Remanufactured: A sustainable middle ground for expensive items like pumps or motors.

Future Trends in Excavator Parts: Innovation for 2026 and Beyond

The future of excavator parts is defined by electrification, automation, and sustainability. With the electric heavy equipment market growing at a CAGR of roughly 24%, we are seeing a shift away from diesel engines toward battery packs and electric actuators.

2026 Outlook

· Electrification: Batteries replacing fuel tanks; electric motors replacing hydraulic pumps.

· Smart Parts: Components with embedded RFID chips for lifecycle tracking.

· 3D Printing: On-demand manufacturing of rare or obsolete mini excavator parts.

· Sustainable Materials: Recycled steel and biodegradable hydraulic fluids becoming standard.

Conclusion

From the robust undercarriage to the precision hydraulic valves, every part of an excavator plays a vital role in its performance. As the industry moves toward 2027, the integration of smart technology and predictive maintenance will redefine how we manage these machines. Whether you are maintaining a mini excavator or a massive mining shovel, understanding these components is the key to profitability.

Frequently Asked Questions (FAQ)

What are the three main sections of an excavator?

Excavators are typically divided into three main sections: the undercarriage (for mobility and stability), the superstructure or house (containing the engine, cab, and hydraulic systems), and the workgroup or front attachment (comprising the boom, arm, and bucket for digging and lifting).

What is the most important part of an excavator?

While all parts are crucial for overall function, the hydraulic system is arguably the most important, as it powers the entire workgroup (boom, arm, bucket) and many other critical movements of the excavator. Without a functioning hydraulic system, the machine cannot perform its primary tasks.

How often should excavator parts be replaced?

Replacement frequency varies greatly depending on the specific part, operating conditions, machine usage hours, and maintenance practices. Wear parts like ground engaging tools (bucket teeth) and undercarriage components require more frequent inspection and replacement than structural components. Always refer to the manufacturer's recommendations and conduct regular inspections.

What is the difference between OEM and aftermarket excavator parts?

OEM (Original Equipment Manufacturer) parts are made by the original company that produced your excavator, ensuring exact fit and quality, usually with a warranty. Aftermarket parts are produced by third-party manufacturers; they can be more affordable but vary in quality, fit, and warranty.

What role does the counterweight play in an excavator?

The counterweight, typically located at the rear of the excavator's superstructure, is essential for stability. It balances the weight of the workgroup (boom, arm, bucket) and any material being lifted, preventing the machine from tipping over during operation, especially when lifting heavy loads.

How does the hydraulic system work in an excavator?

The hydraulic system uses pressurized fluid to transmit power. An engine-driven pump pressurizes hydraulic fluid, which is then directed through control valves to hydraulic cylinders and motors. These cylinders and motors convert the fluid pressure into linear (for boom, arm, bucket) or rotary motion (for swing drive, tracks) to operate the excavator's functions.

What are ground engaging tools (GET)?

Ground engaging tools (GET) are components of the excavator's workgroup that directly contact the ground or material during operation. These include bucket teeth, cutting edges, side cutters, and ripper shanks, which are designed to withstand high abrasion and impact forces, and are considered wear parts.

Can I use parts from different excavator brands?

Generally, it's not recommended to interchange major components between different excavator brands due to variations in design, specifications, and fit. However, some aftermarket parts may claim compatibility across multiple brands. Always verify compatibility with a reputable supplier or manufacturer to avoid damage or safety issues.

References

· Top 7 Trends in Heavy Equipment Market in 2025

· Construction Machinery Telematics Market Size & Growth

· Excavator Market Share, Size, Trends Report

Fixing Oil Cooler Leaks in Heavy Machinery: A Complete Guide

Engine Oil Leak Repair Costs: A Comprehensive Guide

Hyundai & Doosan Wheel Excavator Parts Supplier | Complete Range of Replacement Components

Kubota Error Codes: A Comprehensive Diagnostic & Reset Manual

How to Resolve Error Code P0037: A Comprehensive Guide

faq

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

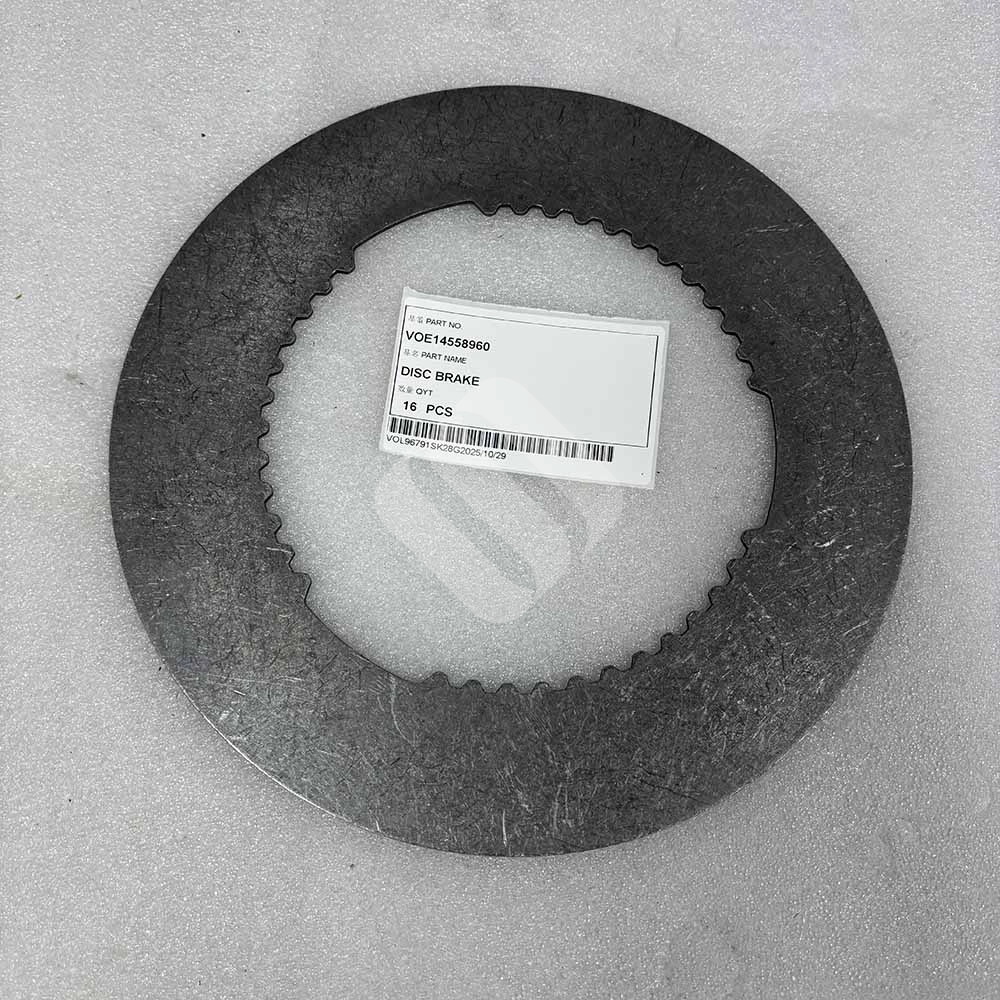

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C VOE14558960 DISC BRAKE SPARKLING MACHINERY

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C VOE14558960 DISC BRAKE SPARKLING MACHINERY

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW 236D 242D 246C 246D 256C 257D 262-3764 SENSOR SPARKLING MACHINERY

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW 236D 242D 246C 246D 256C 257D 262-3764 SENSOR SPARKLING MACHINERY

KOMATSU MADE IN CHINA SPARKLING MACHINERY NEW 3078150 SENSOR

KOMATSU MADE IN CHINA SPARKLING MACHINERY NEW 3078150 SENSOR

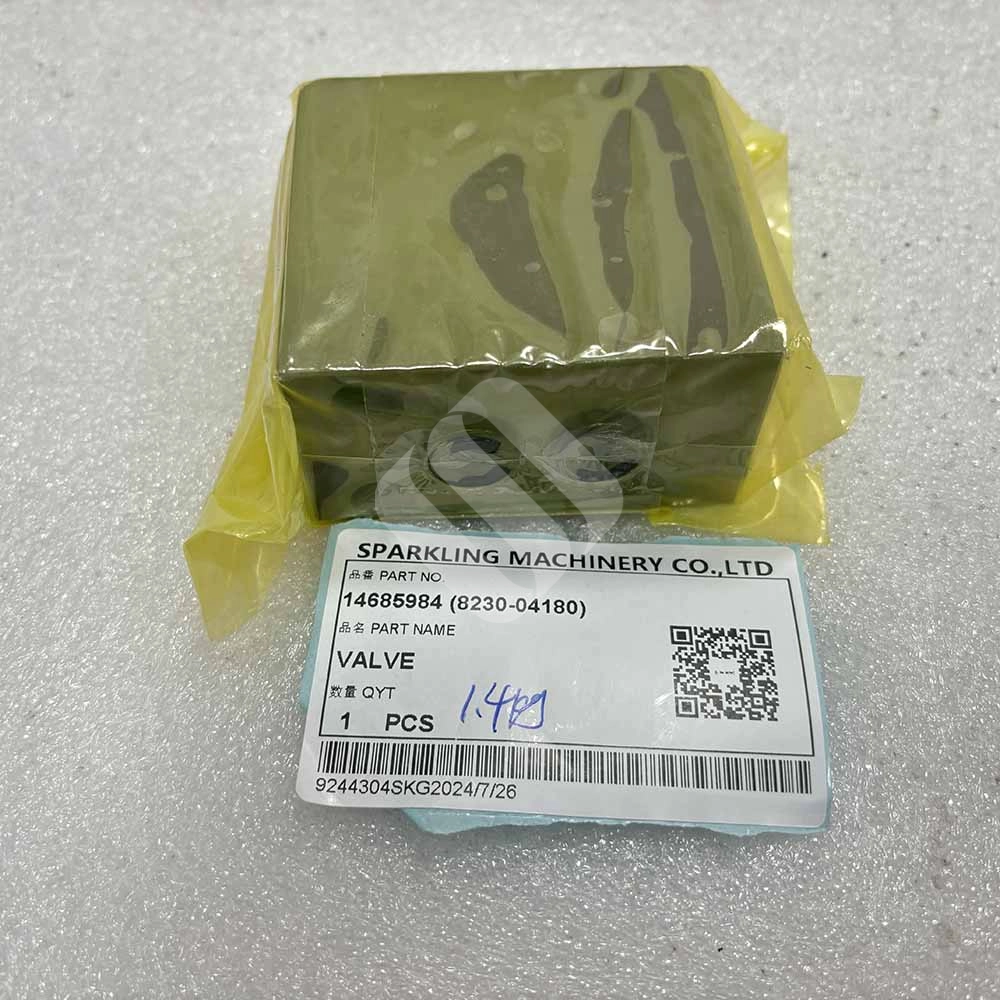

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC350E EC380EHR 14685984(8230-04180) VALVE SPARKLING MACHINERY

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC350E EC380EHR 14685984(8230-04180) VALVE SPARKLING MACHINERY

Case EXCAVATOR PARTS MADE IN CHINA NEW CX350C CX290B CX300C CX800B CX460 KHH10850 RESERVE TANK SPARKLING MACHINERY

Case EXCAVATOR PARTS MADE IN CHINA NEW CX350C CX290B CX300C CX800B CX460 KHH10850 RESERVE TANK SPARKLING MACHINERY

MADE IN CHINA SPARKLING MACHINERY PHV-4B-60B-P9067A FINAL DRIVE

MADE IN CHINA SPARKLING MACHINERY PHV-4B-60B-P9067A FINAL DRIVEGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879