Understanding the Key Parts of an Excavator and Their Functions 2026

This authoritative guide breaks down the anatomy of an excavator, detailing the functions of critical components from the undercarriage to the hydraulic system. It offers expert insights on maintenance, troubleshooting, and sourcing strategies for OEM and aftermarket parts.

- Introduction: Understanding the Backbone of Heavy Machinery

- The Anatomy of an Excavator: Main Structural Divisions

- Undercarriage: The Foundation of Mobility and Stability

- Superstructure (House): The Powerhouse and Control Center

- Operator Cab and Safety

- Engine and Hydraulics

- Workgroup: The Business End of Digging and Lifting

- Essential Wear Parts: Maximizing Lifespan and Performance

- Ground Engaging Tools (GET)

- Undercarriage Wear

- Maintenance & Troubleshooting: Keeping Your Excavator Running Strong

- Sourcing Excavator Parts: A Strategic Buyer's Guide

- OEM vs. Aftermarket

- Global Sourcing

- Advanced Insights & The Future of Excavator Parts

- Conclusion: Investing in Knowledge and Quality for Excavator Longevity

- Key Parts of an Excavator and Their Functions

- Frequently Asked Questions

- What are the main categories of excavator parts?

- How often should excavator wear parts like bucket teeth be replaced?

- What's the difference between OEM and aftermarket excavator parts?

- Why is the hydraulic system so crucial for an excavator's function?

- What are the signs of wear in an excavator's undercarriage?

- Can I use parts from different excavator brands interchangeably?

- What safety features are found in an excavator's cab?

- How can I extend the lifespan of my excavator parts?

- References

Introduction: Understanding the Backbone of Heavy Machinery

Excavators are the undisputed heavyweights of the construction, mining, and forestry industries. Their ability to dig, lift, and maneuver in challenging terrain relies on a complex symphony of mechanical and hydraulic systems. For operators, fleet managers, and technicians, a deep understanding of excavator parts is not merely academic—partnering with experienced excavator parts manufacturers helps ensure proper component selection and system compatibility; it is essential for ensuring operational safety, maximizing machine longevity, and minimizing costly downtime—especially when working closely with reliable excavator parts manufacturers.

Whether you are sourcing parts of an excavator for a massive mining shovel or looking for mini excavator parts for a landscaping project, knowing how these components function together is the first step toward efficient fleet management. This comprehensive guide will dissect the machine into its core structural divisions, explore the critical parts of an excavator, and provide actionable strategies for maintenance and sourcing.

The Anatomy of an Excavator: Main Structural Divisions

To understand the parts of an excavator, it is helpful to visualize the machine in three primary sections: the Undercarriage, the Superstructure (or House), and the Workgroup (Front Attachment). Each section houses specific components that integrate to perform complex tasks.

· Undercarriage: Provides the foundation for mobility and stability.

· Superstructure: Acts as the control center and powerhouse, housing the engine and hydraulics.

· Workgroup: The functional arm responsible for digging and lifting.

Undercarriage: The Foundation of Mobility and Stability

The undercarriage is often the most expensive system to repair, accounting for a significant portion of a machine's lifetime maintenance cost. Understanding excavator undercarriage parts is crucial for preventing premature wear.

· Tracks: These provide traction and flotation. Mini excavator parts often include rubber tracks to minimize damage to paved surfaces, while heavy-duty machines use steel tracks for durability on aggressive terrain.

· Track Frame: This is the rigid structural support that connects the moving parts of the undercarriage to the rest of the machine.

· Rollers (Upper & Lower):

o Bottom Rollers: Support the weight of the excavator and distribute it along the track.

o Top (Carrier) Rollers: Guide the track chain and prevent it from sagging.

· Sprockets: Located at the rear, these toothed wheels engage the track links to drive the machine. As noted by industry resources like Team Excavator Parts, sprockets transfer engine power directly to the tracks.

· Idlers: Positioned at the front, idlers guide the track and contain a tensioning mechanism (often a recoil spring) to absorb shock.

· Final Drives: These distinct units house the hydraulic motors and gears that actually propel the sprockets.

· Slewing Ring (Swing Bearing): This massive bearing connects the undercarriage to the superstructure, allowing the continuous 360-degree rotation that defines hydraulic excavator operation.

Superstructure (House): The Powerhouse and Control Center

The superstructure sits atop the undercarriage and contains the vital organs of the machine.

Operator Cab and Safety

Modern cabs are designed for ergonomics and safety. Crucially, they must meet ISO standards for ROPS (Roll-Over Protective Structures) and FOPS (Falling Object Protective Structures). For example, ISO 12117-2 dictates specific performance requirements for excavators over 6 tons to ensure operator survival in a rollover event, as detailed by standardization bodies like SIS.

Engine and Hydraulics

The engine provides the mechanical energy that drives the hydraulic pumps. While large machines use powerful diesel engines, compact models may require specialized parts for small engines, such as compact diesel units optimized for efficiency.

· Hydraulic Pump: The heart of the system. It converts mechanical power into hydraulic flow. A failing hydraulic pump is a critical issue, as it results in a total loss of power for the boom, arm, and bucket.

· Swing Motor: This hydraulic motor, paired with a gearbox, drives the slewing ring, enabling the house to rotate.

· Cooling System: Includes radiators and oil coolers to maintain optimal operating temperatures for the engine and hydraulic fluid.

Workgroup: The Business End of Digging and Lifting

The workgroup consists of the components that directly engage with the material. When sourcing parts for excavator repairs, this area often requires frequent attention due to high stress.

· Boom: The main arm attached to the superstructure. Options include mono-booms for general use and articulating booms for confined spaces.

· Arm (Stick/Dipper): Connects to the boom and holds the bucket. Its length determines the digging depth.

· Bucket: Available in various types (rock, trenching, clean-up). The bucket is the primary connection point for Ground Engaging Tools (GET).

· Hydraulic Cylinders: These actuators extend and retract to move the boom, arm, and bucket.

Essential Wear Parts: Maximizing Lifespan and Performance

Wear parts are sacrificial components designed to protect the machine's expensive structural elements. Neglecting these parts for excavator maintenance can lead to catastrophic failure.

Ground Engaging Tools (GET)

GET includes bucket teeth, adapters, cutting edges, and side cutters. According to Gregory Poole Equipment Company, selecting the right GET—such as using pointed teeth for rock penetration versus flat teeth for grading—is critical for efficiency.

Undercarriage Wear

Track pads, chains, and rollers are constant wear items. Regular inspection of "grousers" (the cleats on track shoes) is necessary to ensure traction is maintained.

Maintenance & Troubleshooting: Keeping Your Excavator Running Strong

A proactive maintenance schedule is the best defense against downtime.

· Hydraulic System: Monitor for slow operation or whining noises, which often indicate air in the system or a worn hydraulic pump.

· Undercarriage: Clean out mud daily. Hardened mud can increase tension on the tracks, accelerating wear on sprockets and idlers.

· Engine: For smaller machines, ensure you have access to parts for small engines like fuel filters and air filters, which are prone to clogging in dusty environments.

Sourcing Excavator Parts: A Strategic Buyer's Guide

When buying excavator spare parts, the market offers several paths. The choice often depends on budget, machine age, and urgency—especially when selecting the right wheel excavator parts for machines that demand higher mobility and stability.

OEM vs. Aftermarket

· OEM (Original Equipment Manufacturer): These parts guarantee a perfect fit and usually come with a robust warranty. They are the safest choice for critical components like hydraulic pumps or electronic control units.

· Aftermarket: Often more affordable and widely available. High-quality aftermarket suppliers can offer excellent value, especially for older machines.

Global Sourcing

The market for chinese mini excavator parts has grown significantly. While these parts can be cost-effective, buyers must be vigilant about verifying quality standards and ensuring compatibility with their specific machine models.

Advanced Insights & The Future of Excavator Parts

The industry is shifting toward "smart parts." Integrated sensors in hydraulic cylinders can now monitor pressure and position in real-time, feeding data to predictive maintenance systems. Furthermore, the rise of electric excavators is introducing new component categories, such as high-voltage battery packs and electric swing motors, reducing the reliance on traditional diesel engine parts.

Conclusion: Investing in Knowledge and Quality for Excavator Longevity

Understanding the functions of the key parts of an excavator empowers owners to make smarter maintenance and purchasing decisions. Whether you are replacing a simple bucket tooth or overhauling a complex hydraulic pump, prioritizing quality and adhering to maintenance schedules ensures your machinery remains a profitable asset. By balancing the use of OEM reliability with cost-effective aftermarket solutions, you can optimize the lifecycle of your equipment.

Key Parts of an Excavator and Their Functions

|

Part Category |

Component |

Primary Function |

Common Wear Signs |

|

Undercarriage |

Sprocket |

Drives the track chain |

Pointed/sharp teeth |

|

|

Idler |

Maintain track tension & guide chain |

Cracks, uneven wear |

|

|

Track Shoe |

Provides traction & flotation |

Worn grousers (cleats) |

|

Superstructure |

Hydraulic Pump |

Generates fluid flow for power |

Whining noise, slow movement |

|

|

Swing Motor |

Rotates the upper housing |

Grinding noise, drift |

|

Workgroup |

Bucket Teeth |

Penetrate soil/rock |

Rounded tips, breakage |

|

|

Boom Cylinder |

Lifts the main arm |

Leaking seals, drifting |

Frequently Asked Questions

What are the main categories of excavator parts?

Excavator parts are broadly categorized into three main sections: the Undercarriage (for mobility and stability), the Superstructure or House (containing the engine, cab, and hydraulic system), and the Workgroup or Front Attachment (including the boom, arm, and bucket).

How often should excavator wear parts like bucket teeth be replaced?

The replacement frequency for wear parts like bucket teeth depends on factors such as soil type, material abrasiveness, usage intensity, and manufacturer recommendations. Regular visual inspection for chips, cracks, or excessive wear is crucial; replacement should occur before performance is significantly impacted or structural damage occurs.

What's the difference between OEM and aftermarket excavator parts?

OEM (Original Equipment Manufacturer) parts are produced by the excavator's original manufacturer, ensuring perfect fit, quality, and often come with a warranty. Aftermarket parts are manufactured by third-party companies, often offering cost savings and wider availability, but quality can vary, requiring careful selection.

Why is the hydraulic system so crucial for an excavator's function?

The hydraulic system is the 'muscle' of an excavator, responsible for powering all major movements including the boom, arm, bucket, swing, and tracks. It uses pressurized fluid to transmit power, enabling the precise and powerful operations excavators are known for.

What are the signs of wear in an excavator's undercarriage?

Common signs of undercarriage wear include reduced track tension, uneven wear on rollers or sprockets, track pads showing significant thinning or damage, unusual noises during movement, and decreased traction or stability. Regular inspections are vital to catch these early.

Can I use parts from different excavator brands interchangeably?

Generally, excavator parts are not interchangeable between different brands or even different models within the same brand without specific confirmation. While some universal components exist, most parts are designed with precise specifications for a particular machine, and using incompatible parts can lead to damage or safety issues.

What safety features are found in an excavator's cab?

Modern excavator cabs are equipped with numerous safety features, including ROPS (Roll-Over Protective Structure) and FOPS (Falling Object Protective Structure) for operator protection, safety belts, emergency stops, warning lights and alarms, rearview cameras, and ergonomic controls to minimize fatigue.

How can I extend the lifespan of my excavator parts?

Extending part lifespan involves adhering to regular maintenance schedules, using high-quality OEM or reputable aftermarket replacement parts, operating the excavator within its specified limits, performing daily inspections to identify and address minor issues promptly, and keeping all systems (engine, hydraulic) clean and well-lubricated.

References

· Team Excavator Parts: Complete Guide to Excavator Undercarriage Components

· Gregory Poole Equipment Company: Guide to Ground Engaging Tools

Hyundai & Doosan Wheel Excavator Parts Supplier | Complete Range of Replacement Components

Kubota Error Codes: A Comprehensive Diagnostic & Reset Manual

How to Resolve Error Code P0037: A Comprehensive Guide

The Definitive Guide to Excavator Diesel Engine Turbochargers: Maximizing Power with High-Performance Forced-Induction Core Components

The Ultimate Guide to Excavator Parts: Anatomy, Functionality & Future Trends for 2026

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

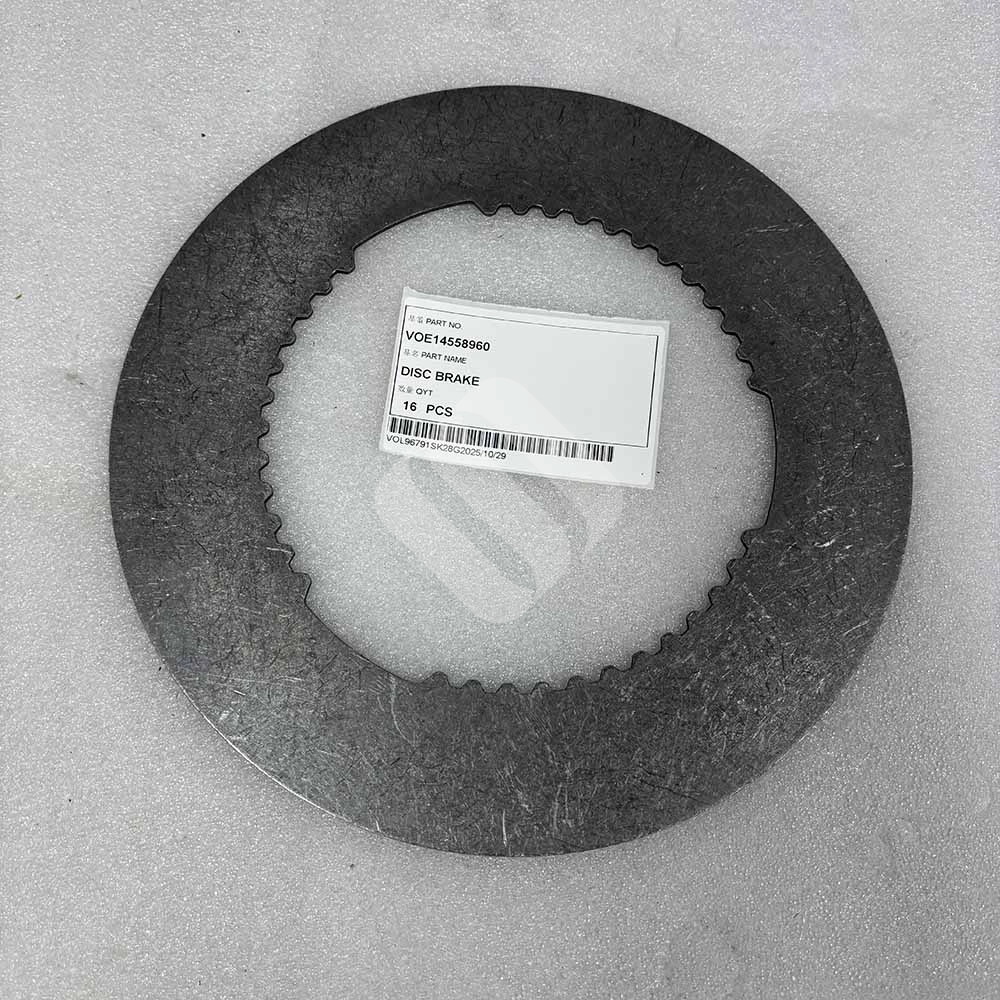

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C VOE14558960 DISC BRAKE SPARKLING MACHINERY

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C VOE14558960 DISC BRAKE SPARKLING MACHINERY

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW 236D 242D 246C 246D 256C 257D 262-3764 SENSOR SPARKLING MACHINERY

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW 236D 242D 246C 246D 256C 257D 262-3764 SENSOR SPARKLING MACHINERY

KOMATSU MADE IN CHINA SPARKLING MACHINERY NEW 3078150 SENSOR

KOMATSU MADE IN CHINA SPARKLING MACHINERY NEW 3078150 SENSOR

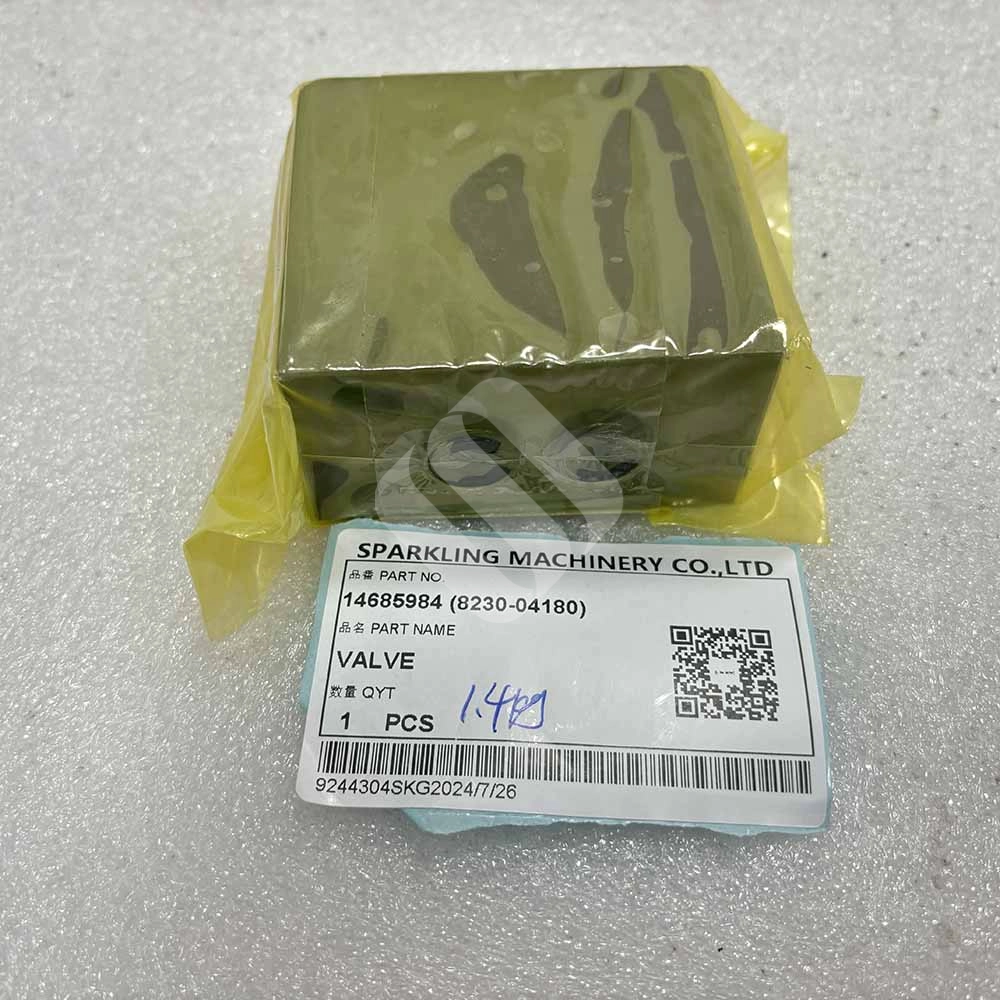

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC350E EC380EHR 14685984(8230-04180) VALVE SPARKLING MACHINERY

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC350E EC380EHR 14685984(8230-04180) VALVE SPARKLING MACHINERY

Case EXCAVATOR PARTS MADE IN CHINA NEW CX350C CX290B CX300C CX800B CX460 KHH10850 RESERVE TANK SPARKLING MACHINERY

Case EXCAVATOR PARTS MADE IN CHINA NEW CX350C CX290B CX300C CX800B CX460 KHH10850 RESERVE TANK SPARKLING MACHINERY

MADE IN CHINA SPARKLING MACHINERY PHV-4B-60B-P9067A FINAL DRIVE

MADE IN CHINA SPARKLING MACHINERY PHV-4B-60B-P9067A FINAL DRIVEGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879