How to Choose the Right Wheel Excavator Parts for Your Machine

Discover expert tips on selecting the best wheel excavator parts for your machine. SPARKLING provides high-quality, durable components to boost your excavator’s performance and lifespan. Learn how to make the right choice today.

- What Are Wheel Excavator Parts and Why They Matter

- Key Components of Wheel Excavator Parts You Should Know

- Signs Your Wheel Excavator Parts Need Replacement

- How to Match the Right Wheel Excavator Parts to Your Brand and Model

- Common Mistakes to Avoid When Buying Wheel Excavator Parts

- Why Quality and Compatibility Are Non-Negotiable for Wheel Excavator Parts

- SPARKLING MACHINERY: Your Trusted Source for Wheel Excavator Parts

- Conclusion: Make Smarter Choices for Your Wheel Excavator’s Longevity

What Are Wheel Excavator Parts and Why They Matter

The components in a wheel excavator are what allow it to work smoothly and are used in road construction, urban excavation, and utility work. Since wheel excavators are more mobile on paved roads, they are preferred for work in cities. Excavators are made up of hydraulic systems, undercarriage components, swing bearings, parts for the boom and arm, and attachments such as buckets or breakers. Understanding all of these parts is necessary because each part has a different effect on how the machine works, stays safe, and lasts.

Even if only one component fails or wears out, the machine’s overall productivity decreases a lot. When components fail, it can cause projects to be delayed, costs to rise, and safety to be threatened. For this reason, having top-quality and properly maintained wheel excavator parts is key to both smooth running and a long life for the machine. Regardless of whether you manage a fleet, fix vehicles, or own equipment, knowing about these parts helps you decide when to repair or replace them.

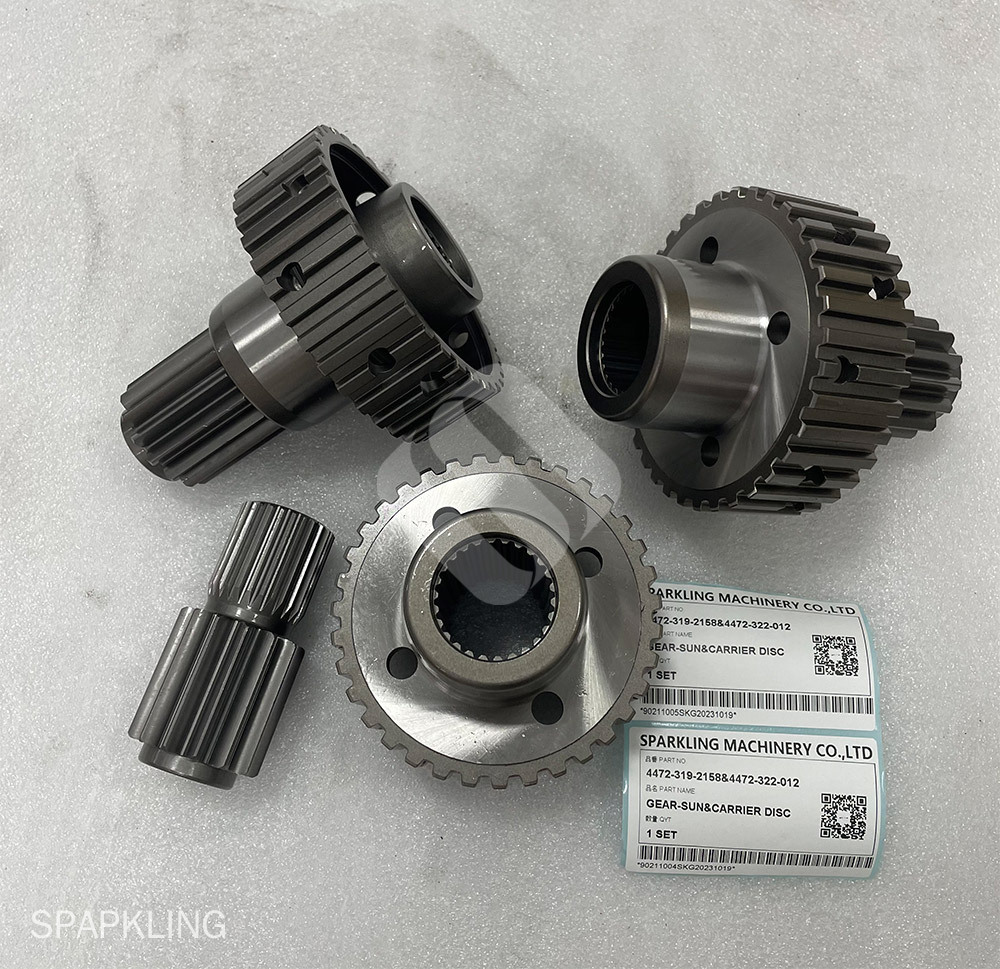

Key Components of Wheel Excavator Parts You Should Know

You should know which parts are most important for the machine’s performance before considering sourcing or replacing wheel excavator parts. Among these are the hydraulic pump and valves, travel motors, axles, tires, transmission system, swing motor, and the control cabin components. Both the hydraulic and travel systems are important for controlling the boom, arm, and attachments, as well as making the machine easy to move. Tires and axles carry the machine’s weight and help reduce shock during operation, which is very important in cities.

In addition, many advanced machines now feature electrical sensors, control systems, and emission systems. They are used with mechanical components to help a vehicle comply with environmental standards and work precisely. It is very important to check that the replacement fits your particular machine model. SPARKLING MACHINERY provides many wheel excavator components that are carefully designed and tested to be dependable under tough conditions.

Signs Your Wheel Excavator Parts Need Replacement

If you don’t notice the first signs of wear or failure in wheel excavator parts, it could result in bigger problems and unplanned downtime. Typical symptoms are a drop in hydraulic performance, strange noises during use, sluggish arm or boom movements, more vibration than usual, and warning lights on the control panel. Usually, these signs suggest that hydraulic parts, swing bearings, or engine components are having problems. If you keep an eye on these symptoms, you can diagnose the problem early and avoid major component failure.

Regular inspections are the strongest way to prevent problems. Look for leaks, loose bolts, uneven tire pressure, or worn-out seals. Operators should keep an eye on how the machine is performing and compare its results with what the manufacturer states. If there are inconsistencies, it’s usually time to inspect or replace the part. If you get your wheel excavator parts from a dependable manufacturer, they will meet the OEM requirements and help your machine run at its best.

How to Match the Right Wheel Excavator Parts to Your Brand and Model

It is often overlooked that excavator maintenance requires using replacement parts that are exactly right for the machine’s brand and model. Both Caterpillar, Komatsu, Hitachi, and Volvo set the dimensions and hydraulic features for each of their machines. If you use different wheel excavator parts, you may notice poor performance, lower efficiency, or quicker wear. Consequently, it is necessary to match parts to the machine’s make and model, not just a preference.

Use your machine’s serial number and OEM part codes as your starting point for choosing the correct replacement. Thanks to these identifiers, suppliers can give you exact products. SPARKLING MACHINERY and similar companies supply many compatible parts for leading global brands. All their components are built to exact standards and tested thoroughly to confirm they are durable, easy to install, and will last a long time. Because they are compatible, the risk of problems is reduced, and the parts fit well into your excavator.

Common Mistakes to Avoid When Buying Wheel Excavator Parts

Buying wheel excavator parts without checking them first can be very expensive. A lot of contractors pick the most affordable option, but this often results in early failures or problems with compatibility. Even though non-OEM parts may look the same, they are often not strong enough and precise enough for tough jobs. It can reduce the vehicle’s performance and also cause problems in other systems, for example, hydraulics or steering.

Many people also make the mistake of not using a specialized wheel excavator parts manufacturer. Suppliers of general machinery might not be aware of the detailed needs of wheel-based systems. Make sure to use suppliers who have a successful history and the necessary skills. When you partner with SPARKLING MACHINERY, you avoid the issues of bad fit, weak materials, and late shipments. If you replace worn parts now, you won’t have to spend more on them later.

Why Quality and Compatibility Are Non-Negotiable for Wheel Excavator Parts

Having good-quality parts makes your excavator work well under tough conditions. Even if low-grade components pass the first tests, they usually break down quickly under pressure, causing more repairs and longer periods when your equipment is not working. Alternatively, wheel excavator parts that are well-made from sturdy materials handle more weight, resist pressure, and remain stable in heat. This is especially important for excavators in construction zones, mines, or public road projects.

The way a product fits is equally as important as how it is made. If a part isn’t a perfect fit, it can cause nearby components to wear out faster and lead to mechanical problems. That’s the reason why choosing SPARKLING MACHINERY which prioritizes OEM compatibility and quality, is very important. All their parts are designed to function and protect the system, which helps the machine work smoothly and last a long time.

SPARKLING MACHINERY: Your Trusted Source for Wheel Excavator Parts

The performance and reliability of your wheel excavator depend greatly on the supplier you choose. The Chinese company SPARKLING MACHINERY is known for always putting quality and compatibility first. The company provides a wide range of wheel excavator parts—hydraulic, engine, and wheel—that are designed for leading brands such as Caterpillar, Komatsu, and Hitachi.

Because of its strict quality, helpful customer service, and ability to ship worldwide, SPARKLING MACHINERY acts as a true partner for its customers. Because they are known for their accuracy and dependable service, contractors, dealers, and repair centers everywhere choose them. Both single-machine and fleet managers can rely on their team to find the right parts for them in a fast and reliable way.

Conclusion: Make Smarter Choices for Your Wheel Excavator’s Longevity

All contractors realize that excavators are essential for finishing construction work on time. Even so, some people do not realize how important it is to use high-quality, compatible parts for wheel excavators. All parts in a car, such as hydraulic systems and wheel assemblies, need to work well to ensure reliability, safety, and efficiency. Choosing the best manufacturer and avoiding cheap parts is a way to make sure your equipment lasts.

All the parts made by SPARKLING MACHINERY are known for being high quality, compatible, and well serviced. Both single parts and large orders can be handled by their team. Get in touch with SPARKLING MACHINERY today to work with a top wheel excavator parts provider and maintain the best performance of your machines.

Hyundai & Doosan Wheel Excavator Parts Supplier | Complete Range of Replacement Components

Kubota Error Codes: A Comprehensive Diagnostic & Reset Manual

How to Resolve Error Code P0037: A Comprehensive Guide

The Definitive Guide to Excavator Diesel Engine Turbochargers: Maximizing Power with High-Performance Forced-Induction Core Components

The Ultimate Guide to Excavator Parts: Anatomy, Functionality & Future Trends for 2026

faq

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Hyundai MADE IN CHINA SPARKLING MACHINERY NEW R140W7 R140W7A R140W9 ZTAM-00571 FLANGE

Hyundai MADE IN CHINA SPARKLING MACHINERY NEW R140W7 R140W7A R140W9 ZTAM-00571 FLANGE

Hyundai MADE IN CHINA SPARKLING MACHINERY NEW R140W-7 ZTAM-00036 FLANGE

Hyundai MADE IN CHINA SPARKLING MACHINERY NEW R140W-7 ZTAM-00036 FLANGE

Hyundai MADE IN CHINA SPARKLING MACHINERY NEW R200W2 4472.320.056 HUB

Hyundai MADE IN CHINA SPARKLING MACHINERY NEW R200W2 4472.320.056 HUB

4472-377-047 Carrier Disc With Big Teeth for HYUNDAI R170W-7 Excavator | High-Quality Wheel Excavator Transmission Parts

4472-377-047 Carrier Disc With Big Teeth for HYUNDAI R170W-7 Excavator | High-Quality Wheel Excavator Transmission Parts

3Kg Gear Pump 9217993 4181700 for Hitachi EX200-1, EX220-1, EX270-1 Excavators & John Deere 120C, 120D – High-Performance Replacement Pump

3Kg Gear Pump 9217993 4181700 for Hitachi EX200-1, EX220-1, EX270-1 Excavators & John Deere 120C, 120D – High-Performance Replacement Pump

3Kg Gear Pump 9218005 4276918 for Hitachi EX120-5, EX200-5, EX220-5 Excavators & John Deere 110, 120, 200LC

3Kg Gear Pump 9218005 4276918 for Hitachi EX120-5, EX200-5, EX220-5 Excavators & John Deere 110, 120, 200LC

512-1242 Excavator Grip Compatible with Caterpillar 320, 320 GC, 330 GC & 336 GC

512-1242 Excavator Grip Compatible with Caterpillar 320, 320 GC, 330 GC & 336 GC

526-8848 Excavator Grip Compatible with Caterpillar 320, 320 GC, 330 GC & 336 GC

526-8848 Excavator Grip Compatible with Caterpillar 320, 320 GC, 330 GC & 336 GC

XKAQ-00760 Shaft Compatible with Hyundai Crawler Excavators R290LC-7, R290LC-9, R300LC-9A & R290LC-9MH

XKAQ-00760 Shaft Compatible with Hyundai Crawler Excavators R290LC-7, R290LC-9, R300LC-9A & R290LC-9MHGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879