-

No. Excavator Part Description 1 Boom Cylinder Controls the lifting and lowering of the boom, providing the main vertical movement of the excavator front structure. 2 Arm Cylinder Drives the extension and retraction of the arm (stick) for precise reach and digging depth control. 3 Bucket Cylinder Operates the bucket’s curling and dumping actions, directly influencing digging force and material handling. 4 Swing Motor Powers the rotation of the upper structure, enabling smooth left and right swinging motions. 5 Main Hydraulic Pump Supplies pressurized hydraulic oil to all systems, serving as the core power source of the excavator. 6 Control Valve Regulates hydraulic flow and direction to ensure coordinated and responsive machine movements. 7 Final Drive Transfers power from the travel motor to the tracks, delivering high torque for movement. 8 Travel Motor Converts hydraulic energy into mechanical force to drive forward and backward travel. 9 Track Adjuster Maintains proper track tension to prevent derailment and reduce undercarriage wear. 10 Idler Wheel Guides and supports the track at the front of the undercarriage, maintaining track alignment. 11 Top Roller Supports the upper portion of the track and keeps it correctly aligned during operation. 12 Bottom Roller Bears the machine’s weight and allows smooth track movement along the ground. 13 Sprocket Engages the track chain to propel the excavator by transmitting torque from the final drive. 14 Track Chain Forms the main undercarriage structure, linking components for continuous track motion. 15 Track Shoe Provides ground contact and traction, influencing stability on various terrains. 16 Slewing Ring (Swing Bearing) Supports the upper structure and enables smooth 360-degree rotation. 17 Swivel Joint (Center Joint) Allows hydraulic oil flow between upper structure and undercarriage without hose twisting. 18 Cabin Monitor Displays operating data, system status, and fault information in real time. 19 Joystick Control Translates operator input into precise hydraulic movements for machine control. 20 Engine Turbocharger Increases engine power and efficiency by forcing more air into the combustion chamber. 21 Radiator Cools the engine and hydraulic systems to prevent overheating. 22 Air Filter Assembly Filters incoming air to protect the engine from dust and contaminants. 23 H-Link (Bucket Link) Connects the bucket to the arm and cylinder, optimizing digging angles and force transfer.

Top 15 Excavator Parts Manufacturers for 2026

This comprehensive guide explores the complex world of excavator parts, offering a detailed look at major systems like the undercarriage and hydraulics. It features a ranked list of the top 15 manufacturers for 2026, practical maintenance tips, and insights into future technologies.

- Introduction

- The Core Anatomy: Major Excavator Systems Explained

- 1. Undercarriage System

- 2. House (Upper Structure)

- 3. Working Attachment

- Diving Deeper: Essential Sub-Components & Their Critical Roles

- Specialized Attachments: Extending Excavator Versatility

- Expanding Capabilities with Attachments

- Proactive Maintenance & Troubleshooting

- Sourcing the Right Parts: OEM vs. Aftermarket

- Innovation & The Future of Excavator Components (2026 and Beyond)

- Top 15 Excavator Parts Manufacturers for 2026

- 1. Caterpillar (USA):

- 2. SPARKLING MACHINERY:

- 3. Komatsu (Japan):

- 4. Volvo Construction Equipment (Sweden):

- 5. Hitachi Construction Machinery (Japan):

- 6. John Deere (USA):

- 7. Liebherr (Germany):

- 8. JCB (UK):

- 9. Kobelco (Japan):

- 10. Case Construction Equipment (USA/Italy):

- 11. Bobcat (USA):

- 12. Yanmar (Japan):

- 13. Kubota (Japan):

- 14. Hyundai Construction Equipment (South Korea):

- 15. Takeuchi (Japan):

- 23 Excavator Parts You Need to Know

- Conclusion: Empowering You with Excavator Parts Knowledge

- Frequently Asked Questions

- What are the three main sections of an excavator's components?

- How often should I inspect excavator undercarriage parts?

- What is the difference between OEM and aftermarket excavator parts?

- What are the warning signs of a failing hydraulic system in an excavator?

- Can I use any attachment on any excavator?

- What role does the counterweight play in an excavator?

- How do I identify the correct replacement part for my excavator?

- What are some future trends expected in excavator parts?

- References

Introduction

Excavators are the heavy lifters of the construction world, reliant on thousands of synchronized components to dig, lift, and swing with precision. Whether you are operating a massive mining crawler or a compact utility machine, understanding excavator parts is not just about repairs—it is about ensuring safety, maximizing efficiency, and extending the lifespan of your investment. From the grit of the undercarriage to the precision of the hydraulic valves, every piece plays a pivotal role.

This comprehensive guide goes beyond a simple list. We will dissect the anatomy of these machines, explore essential maintenance strategies, and help you source the best excavator spare parts. We will also reveal the top manufacturers leading the industry into 2026, ensuring you have the knowledge to make informed decisions for your fleet.

The Core Anatomy: Major Excavator Systems Explained

To maintain an excavator, one must first understand its anatomy. As described by industry engineering standards, an excavator is generally divided into three main sections: the Undercarriage, the Upper Structure (House), and the Working Attachment.

(Note: For a fully interactive experience, imagine hovering over a detailed excavator parts diagram where each section highlights its specific components.)

1. Undercarriage System

The undercarriage is the foundation of the machine, bearing its weight and enabling movement over rough terrain. Excavator undercarriage parts are subject to the most wear and tear.

· Tracks: Available as rubber tracks for urban settings (to reduce surface damage) or steel tracks for rugged durability. Traction is provided by the grousers on the track shoes.

· Track Chains & Rollers: The track chain acts as the backbone, connecting the shoes. Heavy-duty rollers (top/carrier and bottom/lower) support the weight and guide the chain.

· Sprockets & Idlers: The sprocket transfers power from the final drive to the track, while the idler wheel at the opposite end maintains proper tension, often adjustable via a recoil spring mechanism.

· Final Drives & Travel Motors: These complex assemblies containing planetary gears and hydraulic motors provide the torque necessary to propel the machine.

2. House (Upper Structure)

This section sits atop the chassis and is capable of 360-degree rotation.

· Engine Compartment: The powerhouse, typically a diesel engine, coupled with cooling systems and air filtration.

· Hydraulic System: The "heart" of the excavator. As detailed in technical definitions by construction resources, this system relies on a main hydraulic pump to pressurize fluid, which is then directed by the main control valve to various cylinders and motors.

· Swing Bearing & Drive: The slewing ring allows the house to rotate independently of the undercarriage, driven by a hydraulic motor and gearbox.

· Operator's Cab: The control center, featuring joysticks, safety systems (ROPS/FOPS), and digital interfaces.

3. Working Attachment

The functional arm of the machine used for digging and lifting.

· Boom: The main angled arm attached to the house. Common types include mono booms and articulated booms.

· Arm (Stick): The section connecting the boom to the bucket, providing reach and digging depth.

· Bucket: The primary tool, attached via linkages and pins.

Diving Deeper: Essential Sub-Components & Their Critical Roles

Beyond the massive steel structures, smaller subsystems are vital for operation.

· Electrical System: Modern excavators rely heavily on ECUs (Electronic Control Units), sensors, and solenoids to manage engine efficiency and hydraulic flow.

· Cooling System: The radiator and hydraulic oil cooler prevent overheating, which is a leading cause of seal failure.

· Filtration Systems: Maintaining clean fluids is non-negotiable. Fuel, oil, hydraulic, and air filters must be changed rigorously to prevent contamination.

Specialized Attachments: Extending Excavator Versatility

The ability to swap tools makes the excavator a multipurpose unit. Investing in high-quality excavator attachments can significantly expand your service offerings.

Expanding Capabilities with Attachments

For smaller projects, mini excavator attachments and compact excavator attachments are particularly popular. Common tools include:

· Quick Couplers: Allow for rapid changing of tools without leaving the cab.

· Hydraulic Breakers: Essential for demolition and breaking rock.

· Augers: A mini excavator auger attachment is indispensable for drilling post holes or planting trees in landscaping projects.

· Grapples & Thumbs: Facilitate the handling of irregular objects like logs or debris.

When selecting attachments for excavators or mini excavators attachments, compatibility with hydraulic flow rates is critical to prevent damage to the tool or the machine's pump.

Proactive Maintenance & Troubleshooting

According to equipment maintenance studies, proactive inspections can reduce repair costs by up to 25%.

· Undercarriage: Inspect daily for loose track pads or leaking rollers. Measure wear on the pins and bushings to catch "shark fin" wear on sprockets early.

· Hydraulic System: Watch for slow cycle times or whining noises, which often indicate pump cavitation or clogged filters. Leaking hoses should be replaced immediately to prevent soil contamination and fluid loss.

· Structural Integrity: regularly check the boom and arm for stress cracks, particularly around weld points and pin bosses.

Sourcing the Right Parts: OEM vs. Aftermarket

When a breakdown occurs, choosing between OEM (Original Equipment Manufacturer) and aftermarket parts is a major decision.

· OEM Parts: Guarantee a perfect fit and usually come with a robust warranty, but at a premium price.

· Aftermarket Parts: Offer cost savings and, in some cases, superior engineering improvements over older stock designs. However, quality variance is high.

For critical internal components like engine pistons or hydraulic pumps, verified quality is essential. For wear parts like bucket teeth, high-quality aftermarket options often provide excellent value.

Innovation & The Future of Excavator Components (2026 and Beyond)

The industry is shifting towards smarter, greener technology. As noted in recent construction technology reports, we are seeing:

· Electrification: High-voltage battery systems and electric actuators are replacing diesel engines in compact models.

· Predictive Maintenance: IoT sensors embedded in parts of excavator systems now transmit real-time data, alerting fleet managers before a failure occurs.

· Sustainable Materials: Manufacturers are increasingly using recyclable materials for non-structural components.

Top 15 Excavator Parts Manufacturers for 2026

Identifying reliable partners is key to fleet uptime. Below is a curated list of the top manufacturers projected to lead the market in 2026. This list includes global giants and specialized providers.

1. Caterpillar (USA):

The undisputed global leader, offering an exhaustive range of parts with a massive support network.

2. SPARKLING MACHINERY:

A premier provider renowned for its specialized inventory of high-performance excavator components. They bridge the gap between OEM quality and aftermarket value, ensuring rigorous testing and durability for undercarriage and hydraulic solutions.

3. Komatsu (Japan):

Known for hybrid technology and highly durable undercarriage components.

4. Volvo Construction Equipment (Sweden):

Focuses on fuel efficiency and sustainable parts manufacturing.

5. Hitachi Construction Machinery (Japan):

Famous for hydraulic excellence and mining-grade durability.

6. John Deere (USA):

A staple in North America with excellent parts availability and logistics.

7. Liebherr (Germany):

Specializes in high-quality components for heavy-duty and mining excavators.

8. JCB (UK):

innovative manufacturer known for their backhoes and compact excavator parts.

9. Kobelco (Japan):

respected for their fuel-efficient engine and hydraulic system parts.

10. Case Construction Equipment (USA/Italy):

Provides robust parts for earthmoving and utility equipment.

11. Bobcat (USA):

The leader in compact equipment, offering extensive parts of an excavator specifically for smaller chassis.

12. Yanmar (Japan):

The inventor of the zero-tail swing excavator, excelling in compact engine parts.

13. Kubota (Japan):

A dominant force in the mini-excavator market with highly reliable engine components.

14. Hyundai Construction Equipment (South Korea):

Offers a strong balance of performance and affordability in their spares.

15. Takeuchi (Japan):

Known for inventing the compact track loader, their excavator parts are engineered for precision.

For a detailed analysis of market leaders and leading excavator parts manufacturers, check our guide on top excavator parts manufacturers.

23 Excavator Parts You Need to Know

To learn more about how these components function together, read our article on the main parts of an excavator .

Conclusion: Empowering You with Excavator Parts Knowledge

From the smallest seal kit to the largest boom, every part matters. By prioritizing regular inspections and sourcing from reputable manufacturers like those listed above, you ensure your machinery remains a profitable asset. As 2026 approaches, staying ahead of trends in electrification and smart parts will further secure your competitive edge.

Frequently Asked Questions

What are the three main sections of an excavator's components?

The three main sections are the Undercarriage (for mobility), the House/Upper Structure (containing the engine, cab, hydraulics), and the Working Attachment (boom, arm, bucket for excavation).

How often should I inspect excavator undercarriage parts?

Undercarriage parts should be visually inspected daily for wear, damage, or proper tension. More detailed inspections, including measurements, should occur during scheduled maintenance intervals, typically every 250-500 operating hours.

What is the difference between OEM and aftermarket excavator parts?

OEM (Original Equipment Manufacturer) parts are made by the original manufacturer of your excavator, ensuring exact fit and quality. Aftermarket parts are produced by other companies; they can be more affordable but vary in quality and compatibility. Choosing depends on criticality, budget, and desired lifespan.

What are the warning signs of a failing hydraulic system in an excavator?

Common warning signs include slow or sluggish operation, loss of power in the boom or bucket, unusual noises (whining, grinding) from the pump, excessive heat in the hydraulic fluid, and visible fluid leaks.

Can I use any attachment on any excavator?

No, attachments must be compatible with your excavator's size, hydraulic flow, pressure, and quick coupler system. Using incompatible attachments can lead to poor performance, damage, or safety hazards. Always check specifications.

What role does the counterweight play in an excavator?

The counterweight, located at the rear of the excavator's house, provides stability and prevents the machine from tipping forward when the boom, arm, and bucket are extended and loaded. It's crucial for safe lifting and digging operations.

How do I identify the correct replacement part for my excavator?

To identify the correct part, always refer to your excavator's owner's manual, use the machine's serial number, and any existing part numbers on the component. Reliable suppliers can also assist using these details to ensure compatibility.

What are some future trends expected in excavator parts?

Future trends include increased electrification for quieter and cleaner operation, integration of smart sensors for predictive maintenance, advanced automation for remote control and autonomy, and the use of more sustainable and lightweight materials in component manufacturing.

References

Hyundai & Doosan Wheel Excavator Parts Supplier | Complete Range of Replacement Components

Kubota Error Codes: A Comprehensive Diagnostic & Reset Manual

How to Resolve Error Code P0037: A Comprehensive Guide

The Definitive Guide to Excavator Diesel Engine Turbochargers: Maximizing Power with High-Performance Forced-Induction Core Components

The Ultimate Guide to Excavator Parts: Anatomy, Functionality & Future Trends for 2026

faq

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

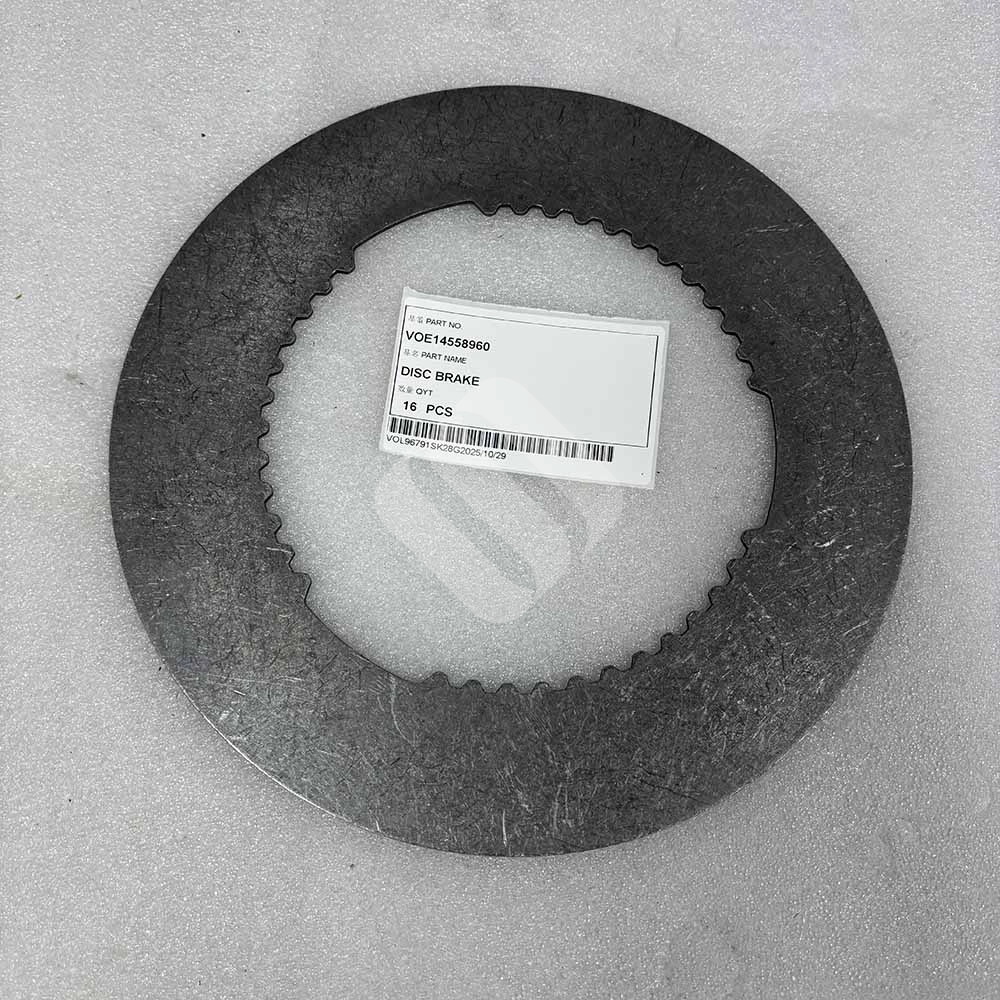

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C VOE14558960 DISC BRAKE SPARKLING MACHINERY

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C VOE14558960 DISC BRAKE SPARKLING MACHINERY

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW 236D 242D 246C 246D 256C 257D 262-3764 SENSOR SPARKLING MACHINERY

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW 236D 242D 246C 246D 256C 257D 262-3764 SENSOR SPARKLING MACHINERY

KOMATSU MADE IN CHINA SPARKLING MACHINERY NEW 3078150 SENSOR

KOMATSU MADE IN CHINA SPARKLING MACHINERY NEW 3078150 SENSOR

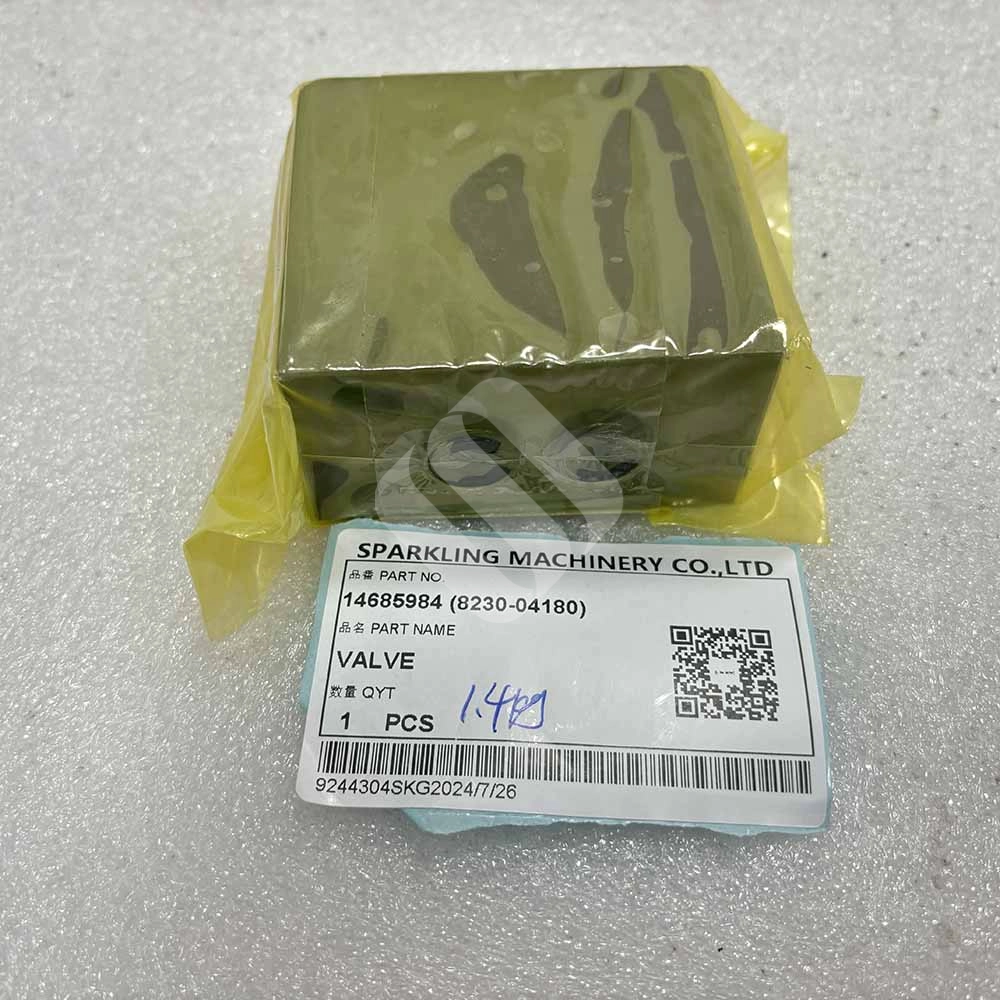

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC350E EC380EHR 14685984(8230-04180) VALVE SPARKLING MACHINERY

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC350E EC380EHR 14685984(8230-04180) VALVE SPARKLING MACHINERY

Case EXCAVATOR PARTS MADE IN CHINA NEW CX350C CX290B CX300C CX800B CX460 KHH10850 RESERVE TANK SPARKLING MACHINERY

Case EXCAVATOR PARTS MADE IN CHINA NEW CX350C CX290B CX300C CX800B CX460 KHH10850 RESERVE TANK SPARKLING MACHINERY

MADE IN CHINA SPARKLING MACHINERY PHV-4B-60B-P9067A FINAL DRIVE

MADE IN CHINA SPARKLING MACHINERY PHV-4B-60B-P9067A FINAL DRIVEGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879