Understanding Excavator Hydraulic Systems: A Comprehensive Guide

- Understanding Excavator Hydraulic Systems: A Comprehensive Guide

- Introduction — Why excavator hydraulic parts matter

- What Is an Excavator Hydraulic System?

- Basic definition and main components

- Key Excavator Hydraulic Parts and Their Roles

- Hydraulic pump — the system’s engine-driven source of flow

- Control valves and pilot systems — directing flow

- Hydraulic cylinders and motors — converting pressure to motion

- Reservoir, filters, and heat exchangers — conditioning the fluid

- Hoses, fittings and seals — the plumbing and integrity

- How Excavator Hydraulic Systems Work: Basic Principles

- Pressure, flow, and power

- Control and coordination

- Common Failure Modes and Prevention

- Contamination — the most frequent root cause

- Overheating and thermal degradation

- Cavitation and aeration

- Seal and hose degradation

- Maintenance Best Practices for Longevity

- Routine inspections and scheduled service

- Fluid selection and oil condition monitoring

- Choosing Quality Excavator Hydraulic Parts

- Material, tolerances and certifications matter

- Compatibility with major brands and aftermarket considerations

- Installation, Troubleshooting and Best Practices

- Proper installation steps

- System diagnostics and simple troubleshooting

- Cost Considerations and ROI of High-Quality Parts

- Balance upfront cost against lifecycle savings

- SPARKLING MACHINERY — Your Partner for Excavator Hydraulic Parts

- Why choose SPARKLING MACHINERY

- Conclusion and Next Steps

- Summary and how to act

- FAQ

- Q1: How often should I change hydraulic filters and oil?

- Q2: Can I use cheaper aftermarket excavator hydraulic parts?

- Q3: What are the warning signs of hydraulic system failure?

- Q4: How important is hydraulic oil cleanliness?

- Q5: Do you supply parts compatible with major excavator brands?

- Q6: What should I do if my hydraulic pump is losing pressure?

Understanding Excavator Hydraulic Systems: A Comprehensive Guide

Introduction — Why excavator hydraulic parts matter

Hydraulics are the heart of an excavator. The reliability and performance of your machine depend directly on the quality and condition of its excavator hydraulic parts. This guide explains core components, how hydraulic systems work, common failure modes, maintenance best practices, and how choosing the right parts reduces downtime and operating cost.

What Is an Excavator Hydraulic System?

Basic definition and main components

An excavator hydraulic system converts engine power into controlled hydraulic energy to move the boom, arm, bucket, swing, and travel functions. Key components include the hydraulic pump, control valves, hydraulic cylinders and motors, hoses and fittings, reservoir, filters, heat exchangers (coolers), accumulators, and seals.

Key Excavator Hydraulic Parts and Their Roles

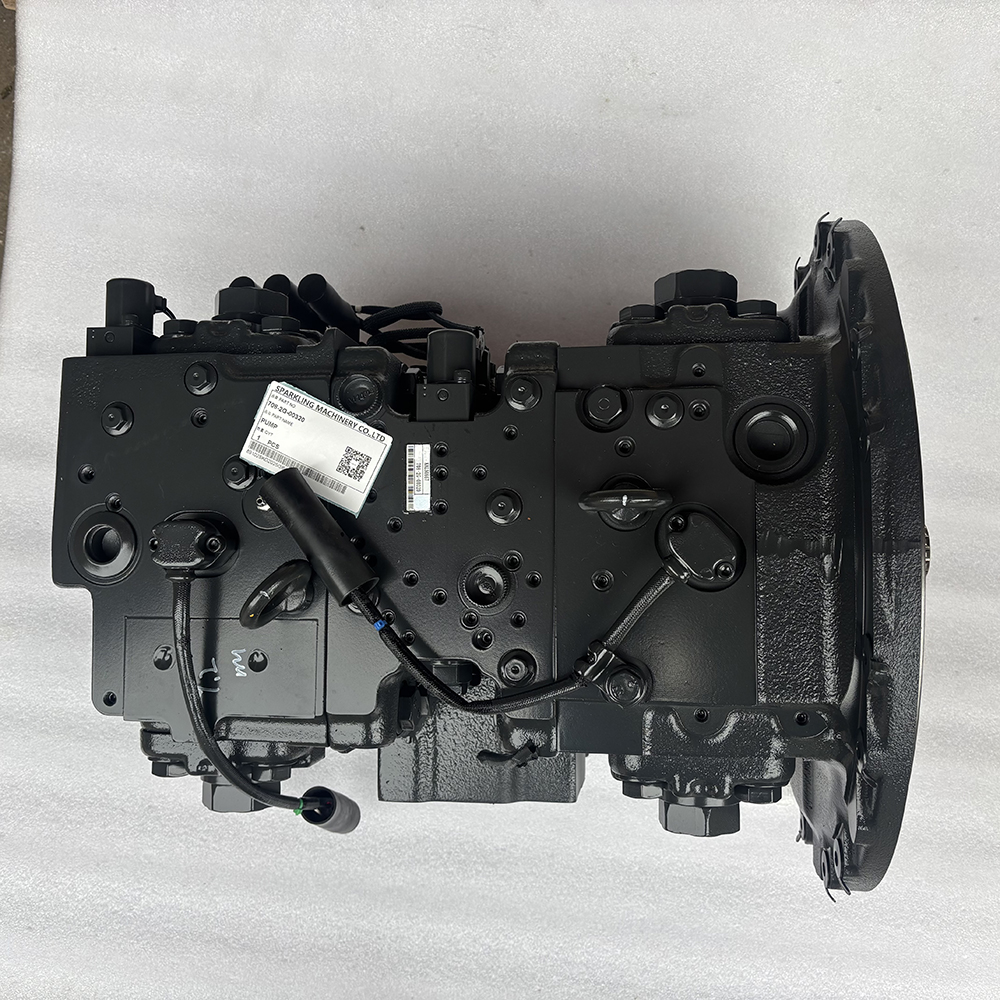

Hydraulic pump — the system’s engine-driven source of flow

The hydraulic pump (often a variable-displacement axial piston pump on modern machines) generates flow and provides system pressure. Pump condition determines how much flow is available for simultaneous functions; a failing pump causes sluggish performance and heat build-up.

Control valves and pilot systems — directing flow

Control (main) valves route pressurized oil to cylinders and motors. Proportional and pilot-operated valves enable smooth, coordinated movements. Valve wear or internal leakage leads to loss of control precision.

Hydraulic cylinders and motors — converting pressure to motion

Cylinders create linear motion (boom, arm, bucket), while hydraulic motors power travel and swing. Cylinder seals, rods, and bearings must be in good condition to maintain efficiency and avoid leaks.

Reservoir, filters, and heat exchangers — conditioning the fluid

The reservoir stores oil and allows air separation, filters remove contaminants, and heat exchangers keep fluid temperatures within operational range. Poor filtration or cooling dramatically shortens component life.

Hoses, fittings and seals — the plumbing and integrity

High-pressure hoses, couplings and seals must withstand system pressures and environmental exposure. Mechanical damage, incorrect routing, or incompatible materials cause leaks and failures.

How Excavator Hydraulic Systems Work: Basic Principles

Pressure, flow, and power

Hydraulic power is the product of pressure and flow. Excavators commonly operate in the range of about 200–350 bar (≈2,900–5,000 psi), depending on machine size and manufacturer. Flow rates vary widely with machine class — from roughly 50 L/min on compact machines to over 300 L/min on large excavators. Higher flow gives faster movement; higher pressure gives higher force.

Control and coordination

Modern systems use load-sensing and electronic controls to allocate flow to multiple circuits. This improves fuel efficiency and responsiveness but requires precise hydraulic parts and clean fluid to function correctly.

Common Failure Modes and Prevention

Contamination — the most frequent root cause

Contaminants (metal particles, dirt, water) cause abrasive wear, clog filters, and damage valves. Prevention: use high-quality filters, keep reservoirs sealed, use correct breather caps, and follow a fluid cleanliness program per manufacturer recommendations.

Overheating and thermal degradation

Excessive fluid temperature reduces viscosity, accelerates oxidation, and damages seals. Ensure coolers are clean, avoid excessive idle heat, and monitor temperatures. If temperatures exceed recommended ranges, inspect for blocked coolers, fan problems, or excessive system loads.

Cavitation and aeration

Air in hydraulic fluid or vapor collapse (cavitation) can erode pumps and produce noise and performance loss. Signs include erratic actuator movement and foamy oil. Check suction lines, reservoir oil levels, and inlet strainers to prevent cavitation.

Seal and hose degradation

Wear, chemical attack, or improper assembly leads to leaks. Replace hoses and seals with compatible, rated parts; inspect routing for abrasion and bending stresses.

Maintenance Best Practices for Longevity

Routine inspections and scheduled service

Establish a maintenance schedule: daily visual checks (leaks, hose condition, oil level), periodic filter replacements, and planned fluid analyses. Typical industry practice is to monitor filters every 250–500 hours and consider full fluid change based on oil analysis — often around 1,000–2,000 hours depending on machine use and oil type. Always follow the OEM manual for precise intervals.

Fluid selection and oil condition monitoring

Use the viscosity and specification recommended by the excavator manufacturer (many use ISO VG 32–68; ISO VG 46 is common for many machines). Regular oil analysis helps detect wear metals, contamination, and oxidation before failures occur.

Choosing Quality Excavator Hydraulic Parts

Material, tolerances and certifications matter

High-quality excavator hydraulic parts are made to exact tolerances, use appropriate heat treatment and surface finishes, and comply with industry standards. Look for supplier certifications, traceability, and warranty terms when selecting pumps, valves, cylinders, or rebuild kits.

Compatibility with major brands and aftermarket considerations

Whether you choose OEM or high-quality aftermarket parts, compatibility with brands like Caterpillar, Komatsu, Hitachi, Volvo, etc., is essential. SPARKLING MACHINERY, founded in 2013, specializes in compatible excavator hydraulic parts and components for top brands and provides customized solutions and technical support to ensure fit and performance. Their product range includes hydraulic components, undercarriage systems, engine and electrical components, cabs, mini excavators and accessories.

Installation, Troubleshooting and Best Practices

Proper installation steps

Key steps: clean work environment, torque to specification, use new seals and fittings, bleed air correctly, and perform function tests under no-load and then incremental load. Use OEM torque values and assembly sequences to prevent distortion and leaks.

System diagnostics and simple troubleshooting

Start with visual checks (leaks, damaged hoses), monitor pressure and temperature readings, and compare to OEM service limits. Use filter particle counts and oil analysis to pinpoint wear sources. When in doubt, consult a hydraulic specialist or the parts supplier’s technical team for root-cause analysis.

Cost Considerations and ROI of High-Quality Parts

Balance upfront cost against lifecycle savings

Higher-quality excavator hydraulic parts often cost more initially but reduce downtime, extend component life, and lower total operating expense. Hidden costs of failures include machine downtime, lost productivity, secondary damage, and expedited shipping for replacements. Investing in proven parts and preventive maintenance provides measurable ROI.

SPARKLING MACHINERY — Your Partner for Excavator Hydraulic Parts

Why choose SPARKLING MACHINERY

Since 2013, SPARKLING MACHINERY has focused on high-quality excavator parts with commitments to stability, precision and perseverance. We offer strict manufacturing and quality control, customized solutions, and technical support. Compatible with Caterpillar, Komatsu, Hitachi, Volvo and other major brands, our products are designed to operate reliably across varied conditions. We combine competitive pricing with continuous service to help customers lower costs and improve uptime.

Conclusion and Next Steps

Summary and how to act

Understanding how excavator hydraulic systems work and selecting quality excavator hydraulic parts are critical to machine performance and operating cost. Implement routine inspections, follow OEM recommendations for fluids and maintenance intervals, and source parts from reputable suppliers. For expert parts, technical support, and tailored solutions, contact SPARKLING MACHINERY to discuss your excavator hydraulic needs and compatible component options.

FAQ

Q1: How often should I change hydraulic filters and oil?

Follow the OEM manual. As a general guideline: inspect filters every 250–500 hours and use fluid analysis to determine oil change timing — commonly between 1,000–2,000 hours depending on conditions and oil type.

Q2: Can I use cheaper aftermarket excavator hydraulic parts?

Quality varies widely among aftermarket parts. Cheaper parts can save money upfront but may increase downtime and damage other components. Choose vendors with proven quality control, compatibility guarantees, and good technical support—such as SPARKLING MACHINERY.

Q3: What are the warning signs of hydraulic system failure?

Watch for sluggish or jerky movements, unusual noises (knocking or whining), overheating, foamy oil, visible leaks, and increased fuel consumption. Early detection prevents catastrophic failures.

Q4: How important is hydraulic oil cleanliness?

Extremely important. Contamination causes most hydraulic failures. Implement proper filtration, sealed reservoirs, and regular oil analysis to keep systems clean and reliable.

Q5: Do you supply parts compatible with major excavator brands?

Yes. SPARKLING MACHINERY provides a wide range of excavator hydraulic parts compatible with Caterpillar, Komatsu, Hitachi, Volvo and other leading brands, backed by manufacturing control and technical support.

Q6: What should I do if my hydraulic pump is losing pressure?

Check for external leaks, inspect suction lines and inlet strainers for blockage (cavitation risk), verify fluid level and condition, and test system pressures. If these checks don’t fix it, consult a specialist to inspect internal pump wear and valve integrity.

Best professional excavator hydraulic pump manufacturers and supplier brands

How to Verify Authentic Hyundai Excavator Parts

How to Verify Compatibility: LC52S00019P1 Low Pressure Sensor

Wholesale excavator left hand column manufacturer and supplier

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

31E3-3187 Accumulator for Hyundai excavators R140W-9 R170W-7 R180W-9 R210W-9 and Case E18C CX37C

The 31E3-3187 Hydraulic Accumulator is a premium diaphragm-type accumulator engineered for Hyundai wheeled excavators (R140W-9/R170W-7/R180W-9/R210W-9) and Case mini-excavators (E18C/CX37C). It stabilizes hydraulic system pressure, absorbs shock waves, and stores energy for peak-demand operations, preventing component fatigue and extending service life in high-vibration construction environments.

Key Features

· OEM-Matched Precision: 0.35L volume, 31.5MPa max working pressure, and diaphragm design for consistent pressure regulation and energy storage.

· High-Strength Construction: Carbon steel body with anti-corrosion coating and reinforced crimped end caps for 10,000+ hours service in harsh conditions.

· Leak-Proof & Shock-Absorbent: Nitrile rubber diaphragm and O-ring seals eliminate fluid leakage; absorbs pressure spikes up to 42MPa to protect valves/pumps.

· Plug-and-Play Fit: Direct bolt-on mounting with 3/4" NPT port; no modification needed for Hyundai/Case excavator installation.

Compatible Equipment

· Excavators: Hyundai R140W-9, R170W-7, R180W-9, R210W-9; Case E18C, CX37C; also fits Hyundai R200W-7, R170W-9.

· Interchangeable Part Numbers: 31E3-3187, 31MN-90680, 31E33187.

Construction Spare Parts VOE14577744 RELIEF VALVE for Volvo Excavators EC330B EC330C EC340D EC360

SPARKLING MACHINERY NEW EC330B EC330C EC340D EC360B EC380D VOE14577744 Relief Valve is a dedicated, high-precision hydraulic component exclusively engineered for VOLVO EC330B, EC330C, EC340D, EC360B, and EC380D crawler excavators—heavy-duty equipment critical for large-scale mining, construction, and infrastructure projects. As a core safety and pressure-regulating part of the excavator’s hydraulic system, it monitors hydraulic pressure in real time and automatically releases excess pressure to prevent overloading of key components like hydraulic pumps, cylinders, and valves. This function is vital for maintaining stable hydraulic operation during high-intensity tasks such as rock breaking, bulk ore loading, and deep excavation, avoiding pressure-surge damage and ensuring uninterrupted workflow.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the genuine part number VOE14577744, the relief valve withstands harsh conditions: high hydraulic pressure (up to 42 MPa), extreme temperature fluctuations (-25°C to 105°C), and continuous heavy-duty vibration. It maintains precise pressure regulation accuracy and resists oil contamination, providing long-lasting reliability for the excavators’ hydraulic systems. Backed by strict performance verification, it guarantees seamless compatibility and operational safety for EC330B/EC330C/EC340D/EC360B/EC380D models.

Rexroth Relief Valve 04950403 R901102333 – 350 Bar Screw‑In Cartridge

The Rexroth Relief Valve 04950403 (part no. R901102333) is a precision-engineered screw-in cartridge valve designed for hydraulic systems in excavators and industrial machinery. This robust, direct-acting spool-type valve offers pressure reducing and relieving capabilities, withstanding up to 350 bar of maximum operating pressure and supporting flow rates around 30 L/min. Constructed with quality materials and standard CAAN cavity compatibility, it ensures responsive, leak-free hydraulic control under demanding conditions.

Premium XKCH-00022 solenoid valve fits Hyundai R125LCR-9A, R145CR9, R160LC9A, and R180LC9S excavators. Reliable hydraulic control part from SPARKLING

The XKCH-00022 Solenoid Valve is a precision-engineered hydraulic control component used in multiple Hyundai crawler excavators, including models R125LCR-9A, R145CR9, R160LC9A, and R180LC9S.

This solenoid valve plays a vital role in directing hydraulic fluid flow in key systems such as travel, swing, or attachment control. Engineered for responsive performance and long-lasting durability, this part ensures accurate actuation and helps maintain overall machine efficiency.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879