Iron Arms Across Centuries: From Steam-Powered Titans to AI-Driven Mavericks, Excavators’ Evolution Shocks the Ages!

From the smoke-belching "early industrial machines" to self-operating "intelligent iron arms", the century-long evolution of excavators is not just a technological iteration, but also embodies the rise of global engineering machinery brands. Today, let’s trace the upgrading path of these steel giants to unlock the key moments and hardcore brands that have reshaped the engineering landscape!

- Ⅰ. First Stage: "Mechanical Enlightenment" in the Steam Era (Late 19th Century - Early 20th Century)

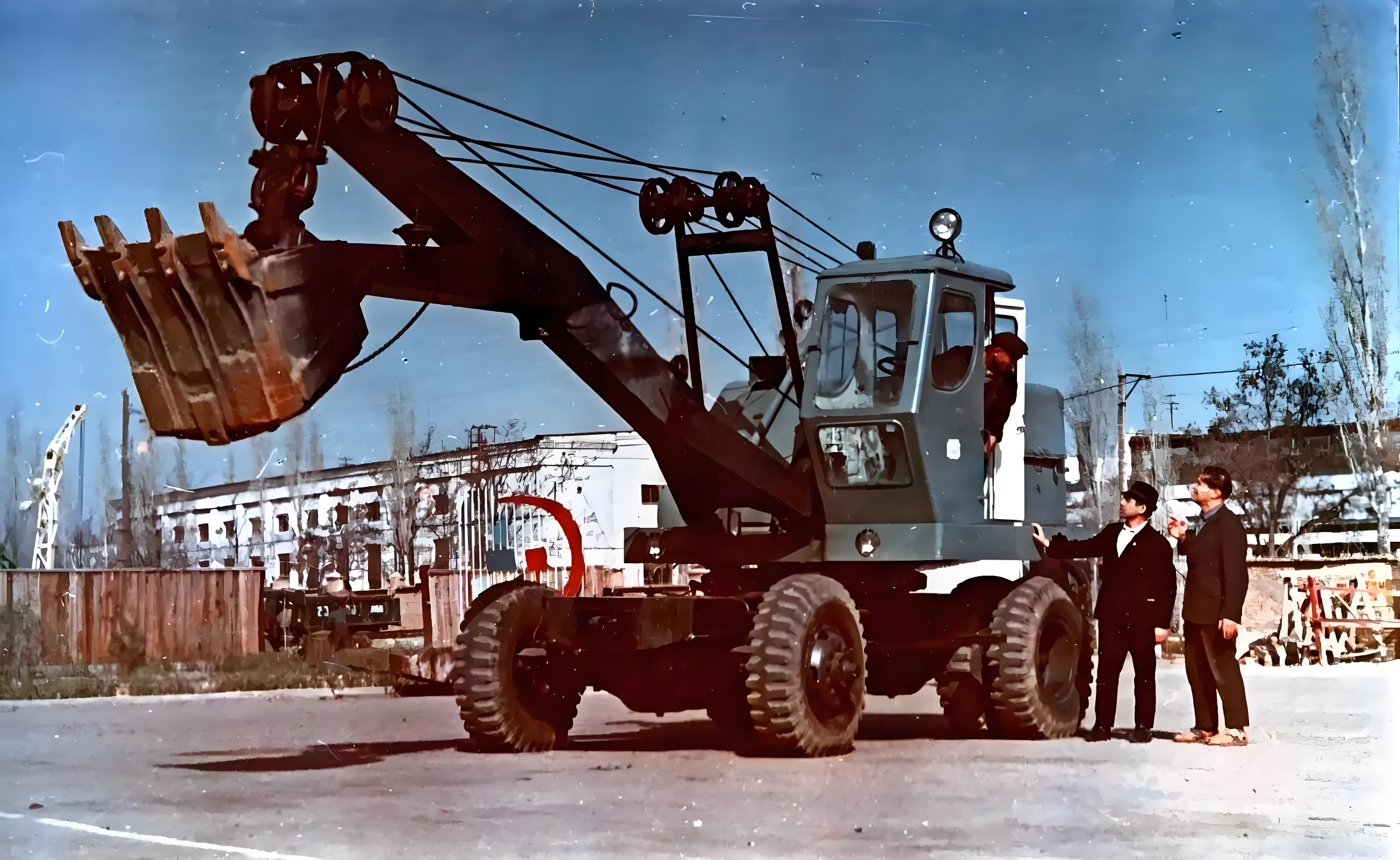

- Ⅱ. Second Stage: "Performance Leap" with Diesel and Hydraulics (Mid-20th Century - 1970s)

- Ⅲ. Third Stage: "Intelligent Germination" through Electronization (1980s - Early 21st Century)

- Ⅳ. Fourth Stage: "The Future Arrives" with Unmanned Operation (Early 21st Century - Present)

- Concluding Questions

Ⅰ. First Stage: "Mechanical Enlightenment" in the Steam Era (Late 19th Century - Early 20th Century)

• Key Node: In 1833, American William Otis invented the world’s first steam shovel, replacing manual excavation with mechanical force for the first time and ushering in the era of engineering machinery.

• Technical Characteristics: Powered by steam, the machine body was as bulky as a "mobile fortress". Its iron arm, driven by gears, moved slowly but with tremendous strength, roaring loudly and belching thick smoke during operation.

• Excavator Brands Established in This Stage:

(Note: This was a period of technological germination, and modern professional excavator brands had not yet taken shape. However, it laid the foundation for mechanical excavation, with the technical origins of subsequent brands traceable to this era.)

• Labor Requirements: 5-8 people were needed to collaborate—some in charge of stoking the boiler and regulating steam pressure, others operating the mechanical arm. Any misstep in teamwork directly hindered efficiency.

• Application Scenarios: Focused on railway construction and large-scale mining, it overcame hard rock formations beyond human capacity, becoming the "pioneer" of large-scale infrastructure after the Industrial Revolution.

• Era Significance: It marked the shift of engineering construction from the "age of human and animal power" to the "age of mechanical power", paving the way for the birth of professional excavator brands later.

Ⅱ. Second Stage: "Performance Leap" with Diesel and Hydraulics (Mid-20th Century - 1970s)

• Key Node: In the 1940s, diesel engines replaced steam power, and hydraulic technology became widespread, transforming excavators from "clumsy giants" into "agile experts".

• Technical Characteristics: Diesel power increased by 30% while energy consumption dropped. Hydraulic systems enabled precise telescoping and rotation of the iron arm, with the machine body trending toward miniaturization and multi-functionality.

• Excavator Brands Established/Rising in This Stage:

-- Caterpillar:

a. Main Markets: The United States (a long-term leader in global market share).

b. Labor Requirements: 1-2 operators, who needed proficiency in precise control of hydraulic joysticks.

c. Application Scenarios: Mining and highway construction, playing a key role in the post-WWII U.S. infrastructure boom.

-- Komatsu:

a. Main Markets: Japan (a core brand in the Asian market).

b. Labor Requirements: Simplified operational procedures, shortening new operator training to 1 month.

c. Application Scenarios: Post-war reconstruction in Japan, adapting to multi-terrain construction needs.

-- Hitachi:

a. Main Markets: Japan and Southeast Asia.

b. Labor Requirements: Emphasized human-machine collaboration, with cab designs tailored to operational habits.

c. Application Scenarios: Municipal engineering and port construction, renowned for durability.

• Era Significance: The "golden combination" of diesel and hydraulics turned excavators from "specialized equipment" into "versatile tools", laying the groundwork for the competitive landscape of professional brands.

Ⅲ. Third Stage: "Intelligent Germination" through Electronization (1980s - Early 21st Century)

• Key Node: Electronic monitoring systems and automatic speed regulation technologies were integrated into designs, pushing excavators into the "data-driven operation" era.

• Technical Characteristics: Cabs were equipped with electronic dashboards that displayed real-time fuel consumption and fault alerts. Some models achieved semi-automatic operation with centimeter-level precision.

• Excavator Brands Established/Expanded in This Stage:

-- Volvo:

a. Main Markets: Sweden (a dominant brand in the European market).

b. Labor Requirements: Operators needed basic skills in electronic equipment debugging, optimizing operations through data feedback.

c. Application Scenarios: Urban construction and environmental projects, featuring low-noise, low-emission models.

-- Doosan:

a. Main Markets: South Korea and global emerging markets.

b. Labor Requirements: Simplified electronic system logic, lowering the barrier for new operators.

c. Application Scenarios: Small and medium-sized infrastructure projects, with significant cost-performance advantages.

-- Hyundai:

a. Main Markets: South Korea, China, and the Middle East.

b. Labor Requirements: Emphasized remote diagnosis to reduce on-site maintenance personnel.

c. Application Scenarios: Residential construction and agricultural water conservancy, adapting to diverse needs.

-- Kobelco:

a. Main Markets: Japan and global high-end markets.

b. Labor Requirements: High-precision operations relied on professional training, suitable for complex projects.

c. Application Scenarios: Tunnel excavation and bridge construction, known for operational accuracy.

• Era Significance: Electronization enhanced "human-machine collaboration" efficiency. Brand competition shifted from "hardware rivalry" to "integration of hardware and software", accelerating globalization.

Ⅳ. Fourth Stage: "The Future Arrives" with Unmanned Operation (Early 21st Century - Present)

• Key Node: 5G, AI, and Beidou positioning were deeply integrated. After 2010, unmanned excavators entered commercial use in mines and high-risk scenarios.

• Technical Characteristics: Sensors and algorithms enabled autonomous navigation and obstacle avoidance, supporting remote monitoring and cluster operations, with real-time cloud synchronization of construction data.

• Leading Excavator Brands in This Stage:

-- Caterpillar:

a. Main Markets: Global (a benchmark in unmanned mining technology).

b. Labor Requirements: No on-site operators needed; only a small team of technicians for remote monitoring and debugging.

c. Application Scenarios: Large open-pit mines, enabling 24/7 non-stop operation.

-- Komatsu:

a. Main Markets: Global (a leader in intelligent construction systems).

b. Labor Requirements: Reduced on-site manpower through pre-construction simulations via digital twin technology.

c. Application Scenarios: Smart construction sites, supporting multi-machine collaborative operations.

-- Volvo:

a. Main Markets: European and Chinese markets.

b. Labor Requirements: Focused on safety monitoring, with full unmanned operation in high-risk segments.

c. Application Scenarios: Urban underground projects and hazardous road construction.

• Era Significance: It marked engineering machinery’s entry into the "intelligent, unmanned era". Brand competition now centers on "technical ecosystem building", redefining standards for engineering safety and efficiency.

Concluding Questions

From multi-person collaboration in the steam era to today’s "unmanned fleets", excavator brands have rewritten engineering history through technology over a century. In the next decade, which brand do you think will first achieve "full-scenario unmanned construction"? What groundbreaking technologies will future excavators unveil?

Top 15 Excavator Parts Manufacturers for 2026

Understanding the Key Parts of an Excavator and Their Functions 2026

Ultimate Guide to Hydraulic Cylinder Components: Anatomy, Function, & Selection for 2025 and Beyond

Christmas Excavators: From Construction Sites to Holiday Heroes!

Volvo Excavator Hydraulic Pump Selection Guide: Original vs. China-Made – How to Choose Without Pitfalls?

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW PC220 PC240 PC290 PC300 PC350 20Y-54-52860 LOCK ASS'Y SPARKLING MACHINERY

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW PC220 PC240 PC290 PC300 PC350 20Y-54-52860 LOCK ASS'Y SPARKLING MACHINERY

Kobelco HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW SK200LC-6ES SK235SRLC-1ES SK235SR-1ES ME077148 RELAY,ALTNT SPARKLING MACHINERY

Kobelco HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW SK200LC-6ES SK235SRLC-1ES SK235SR-1ES ME077148 RELAY,ALTNT SPARKLING MACHINERY

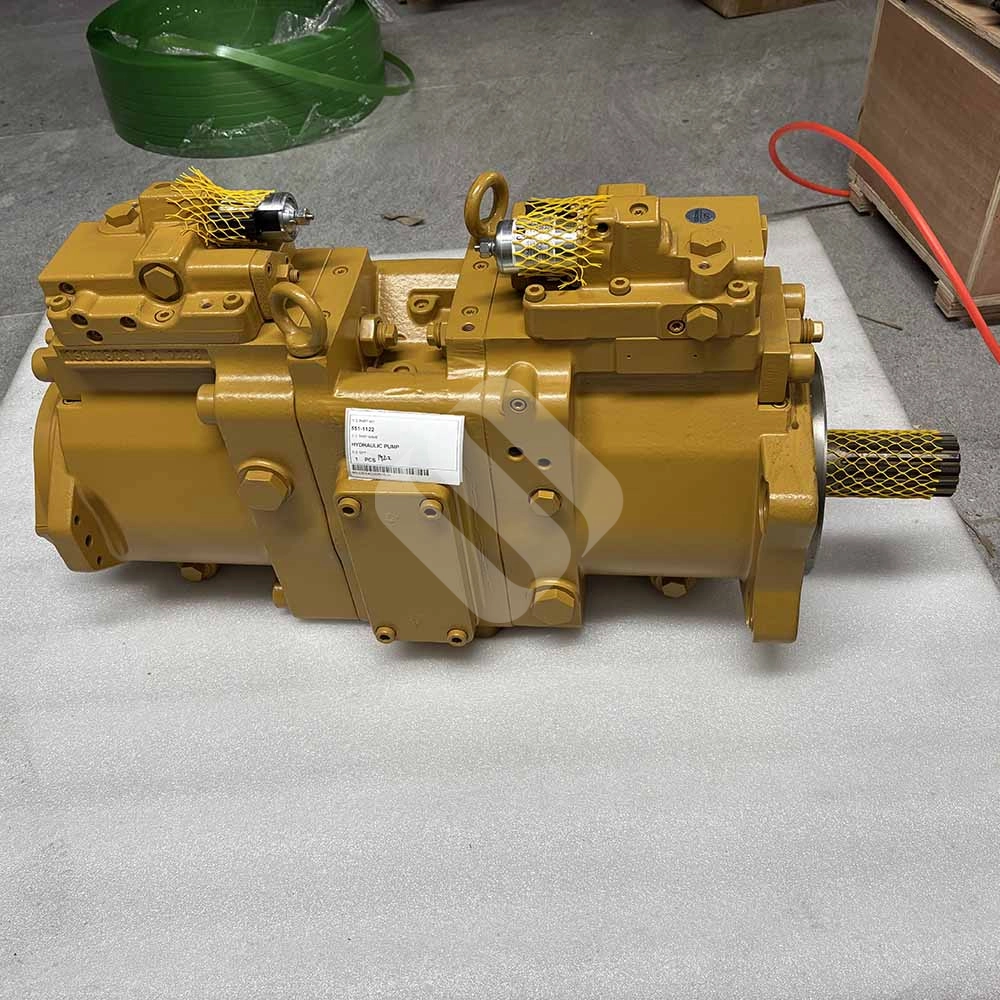

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 330 330GC 551-1122 HYDRAULIC PUMP SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 330 330GC 551-1122 HYDRAULIC PUMP SPARKLING MACHINERY

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW DX180 K9004306 GEAR DRIVE SPARKLING MACHINERY

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW DX180 K9004306 GEAR DRIVE SPARKLING MACHINERY

Atlas Copco HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 1089037601 TEMPERATURE SWITCH SPARKLING MACHINERY

Atlas Copco HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 1089037601 TEMPERATURE SWITCH SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 302.7D 386-0875 3860875 RELIEF VALVE SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 302.7D 386-0875 3860875 RELIEF VALVE SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 120G 120H 130G 140G 140H 135H 6L-8617 RADIATOR CAP SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 120G 120H 130G 140G 140H 135H 6L-8617 RADIATOR CAP SPARKLING MACHINERY

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW FV30 ZX450 ZX450H ZX450H-HHE ZX460LCH-AMS 4435106 CUSHION SPARKLING MACHINERY

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW FV30 ZX450 ZX450H ZX450H-HHE ZX460LCH-AMS 4435106 CUSHION SPARKLING MACHINERY

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 100D-7 50DE 50DEACE 50DF 50DS-7E 80D-7 11LD-20240 HEAD FILTER SPARKLING MACHINERY

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 100D-7 50DE 50DEACE 50DF 50DS-7E 80D-7 11LD-20240 HEAD FILTER SPARKLING MACHINERY

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 301.4C 3792809 TURBOCHARGER SPARKLING MACHINERY

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 301.4C 3792809 TURBOCHARGER SPARKLING MACHINERYGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1