Excavator Unsmooth Movements or Lack of Power? The Issue Is the "Main Control Valve"!

Have you ever faced these frustrations while operating an excavator? The machine jerks when you try to lift the boom and swing the upper structure at the same time; the bucket suddenly loses power when digging hard soil; and a single repair can cost tens of thousands of yuan? In fact, 90% of such problems stem from the Main Control Valve—it acts as the "motion control center" of the excavator. Every movement of the bucket, boom, and tracks relies on it to distribute power. However, many operators only master basic operations, without understanding its working principle, knowing how to choose a reliable model, or performing proper daily maintenance.

This article will explain the main control valve in simple terms: from its structural principle and vulnerability risks to cost-performance comparisons of domestic and international brands, as well as daily maintenance tips. Even beginners can easily grasp this knowledge, helping you reduce repair costs and improve the smoothness of the machine's movements!

- I. Main Control Valve (Multi-Way Valve): The "Motion Control Center" of the Excavator—It Can’t Operate Without It!

- 1. Structure: Similar to a Pipeline Box with Multiple Switches, Easy for Beginners to Understand

- 2. Core Principle: Distribute Hydraulic Oil on Demand to Ensure Smooth Movements

- 3. Importance: It Determines the Smoothness of Movements and Power Output!

- II. The Main Control Valve Needs to Guard Against These 5 Risks! Triggering Any of Them Requires High-Cost Repairs

- 1. Hydraulic Oil Contamination: Easily Causes Spool Jamming

- 2. Long-Term Violent Operation of the Control Lever: Accelerates Spool Wear

- 3. Excessively High Hydraulic Oil Temperature: Easily Causes Valve Body Deformation

- 4. Insufficient Hydraulic Oil or Wrong Oil Type: Easily Causes Component Dry Friction

- 5. Long-Term Overload Operation: The Valve Body Cannot Withstand High Pressure

- III. Cost-Performance Comparison of Domestic and International Main Control Valve Brands

- IV. Main Control Valve Maintenance: Do These 4 Things to Extend Service Life by 3 Years!

- 1. Regularly Replace Hydraulic Oil and Filters: Provide Clean Oil for the "Control Center"

- 2. Operate the Control Lever Smoothly: Avoid Violent Operation and Pressure Stalling

- 3. Regularly Inspect 2 Key Parts: Detect Hidden Troubles Early

- 4. Maintenance During Long-Term Idleness: Prevent Component Aging

- V. Conclusion

I. Main Control Valve (Multi-Way Valve): The "Motion Control Center" of the Excavator—It Can’t Operate Without It!

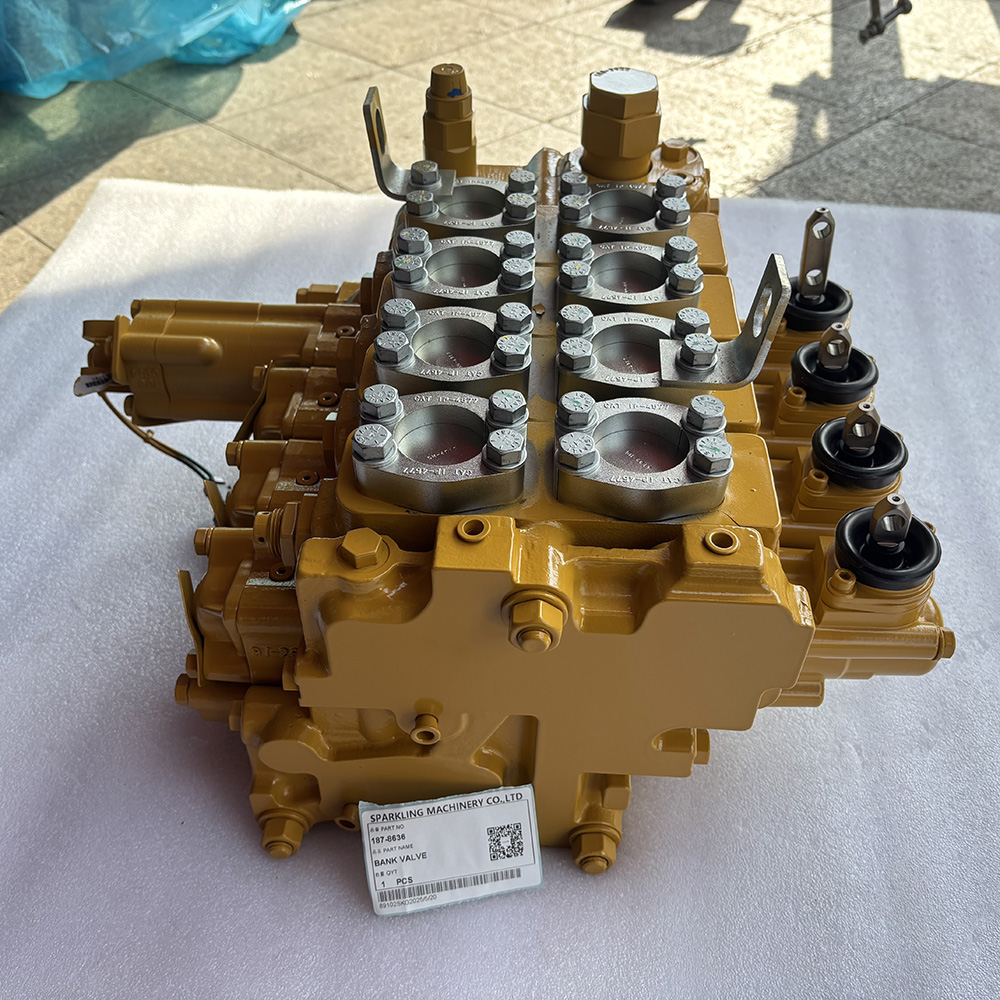

The main control valve, also known as the "multi-way valve", is simply a "hydraulic oil distribution center"—the high-pressure hydraulic oil generated by the main hydraulic pump must be distributed by the main control valve to various executive components such as the boom, bucket, swing mechanism, and travel system before the excavator can perform various movements. Without the main control valve, the excavator is like a "stiff piece of scrap metal", and its specific importance is reflected in the following 3 points:

1. Structure: Similar to a Pipeline Box with Multiple Switches, Easy for Beginners to Understand

The core composition of the main control valve is a "valve body + multiple spools", plus oil pipe interfaces connecting various components. There’s no need to memorize complex part names; just focus on mastering the following 2 key parts:

• Valve Body: Equivalent to a "main pipeline", it has multiple internal channels. After high-pressure hydraulic oil enters from the main pump, it is first stored in the main channel of the valve body, waiting for distribution;

• Spool: Equivalent to a "control switch", each movement (such as lifting the boom or retracting the bucket) corresponds to one spool. When you operate the control lever, the spool moves accordingly, opening the corresponding channel and delivering hydraulic oil to the respective cylinder or motor—for example, when you operate the "boom lift" control lever, the spool corresponding to the boom opens, and hydraulic oil flows into the boom cylinder to drive the boom up.

2. Core Principle: Distribute Hydraulic Oil on Demand to Ensure Smooth Movements

The entire process is similar to a "courier sorting center" and is completed in 3 steps:

1. The main hydraulic pump converts the engine power into high-pressure hydraulic oil and delivers it to the "main inlet" of the main control valve;

2. Operate the control lever (e.g., "retract the bucket"), the corresponding spool moves, opening the channel for the "bucket cylinder";

3. High-pressure hydraulic oil flows into the bucket cylinder through the opened channel, pushing the cylinder to extend or retract, and realizing the retraction of the bucket.

More importantly, the main control valve has the function of "simultaneously distributing hydraulic oil"—for example, when you operate the "boom lift" and "bucket retract" control levers at the same time, the two corresponding spools open synchronously, and hydraulic oil flows into the boom cylinder and bucket cylinder respectively. The machine can complete two movements at the same time, greatly improving work efficiency.

3. Importance: It Determines the Smoothness of Movements and Power Output!

• Determines Movement Smoothness: The more flexible the spool movement of the main control valve and the smoother the channels, the more evenly the hydraulic oil is distributed, and the smoother the excavator's movements—for example, no jerking when swinging the upper structure and lifting the boom at the same time; if the spool gets stuck, the movements will slow down, and the machine may even only perform single movements, reducing daily workload by up to 30%.

• Affects Power Output: The main control valve can adjust the pressure and flow of hydraulic oil. The higher the pressure and the more sufficient the flow, the stronger the movement power—for example, when digging hard rock, the main control valve will distribute higher-pressure hydraulic oil to the bucket cylinder to ensure the bucket can break through the hard rock; if the pressure adjustment function of the main control valve fails, the bucket will lose power and cannot dig normally.

• High Maintenance Costs: The unit price of an imported main control valve is usually 50,000-80,000 yuan (7,140-11,430), and domestic models also cost 15,000-30,000 yuan (2,140-4,290). During maintenance, the machine body needs to be disassembled and hydraulic oil replaced, resulting in a downtime of at least 2-3 days. The loss from work stoppage often exceeds the maintenance cost, making it a "core component with extremely high maintenance costs".

II. The Main Control Valve Needs to Guard Against These 5 Risks! Triggering Any of Them Requires High-Cost Repairs

Although the main control valve seems sturdy, it is actually sensitive to the following 5 types of operations or working conditions. Beginners must avoid them:

1. Hydraulic Oil Contamination: Easily Causes Spool Jamming

When dust, metal debris (e.g., not replacing the filter in time) mixes into the hydraulic oil, it’s like "sand getting into a faucet"—it will get stuck in the gap between the spool and the valve body, causing the spool to fail to move normally. For example, if the spool corresponding to the bucket is stuck, the bucket cannot be retracted when operating the control lever, and the main control valve needs to be disassembled for cleaning. A single maintenance costs about 5,000-10,000 yuan (714-1,429).

2. Long-Term Violent Operation of the Control Lever: Accelerates Spool Wear

Some operators push the control lever "all the way at once" in pursuit of efficiency, causing the spool to move suddenly and quickly, resulting in collision and friction with the valve body—similar to quickly turning a faucet on and off, the spool is prone to wear. Over time, the spool seal will age, leading to hydraulic oil leakage, which manifests as "insufficient movement power and slow speed". Replacing a set of spool seals costs 3,000-8,000 yuan (429-1,143).

3. Excessively High Hydraulic Oil Temperature: Easily Causes Valve Body Deformation

When working in a high-temperature environment in summer or when the hydraulic oil radiator is blocked, the hydraulic oil temperature will exceed 60°C (the normal temperature should be ≤55°C). High temperature will cause the valve body of the main control valve to deform due to heat, narrowing the internal channels and hindering the flow of hydraulic oil. This leads to "jerky and slow movements"; in severe cases, the valve body may crack, requiring the entire main control valve to be replaced, which costs up to tens of thousands of yuan ($1,429+).

4. Insufficient Hydraulic Oil or Wrong Oil Type: Easily Causes Component Dry Friction

• Insufficient Hydraulic Oil: When the main hydraulic pump is short of oil, it will suck in air. After the air enters the main control valve, it forms "air resistance", causing the movements to be "uneven in speed" and accelerating spool wear at the same time;

• Wrong Oil Type: 46# anti-wear hydraulic oil should be used. If 32# hydraulic oil or ordinary engine oil is used by mistake, the oil viscosity will not meet the requirements, resulting in reduced lubrication effect. The wear rate of the spool and valve body will increase by 3 times, and the main control valve may be scrapped within 1-2 years.

5. Long-Term Overload Operation: The Valve Body Cannot Withstand High Pressure

For example, using a 20-ton excavator to frequently dig hard rock, load heavy objects, or keeping the bucket in "full-load pressure" for a long time (e.g., forced pressurization when digging is blocked), the main control valve will be in a "high-pressure state" for a long time. The internal channels of the valve body will be deformed by pressure, and the spool will also wear due to excessive force. A main control valve with a original service life of 5 years may need to be replaced in 3 years.

III. Cost-Performance Comparison of Domestic and International Main Control Valve Brands

|

Brand Type |

Excavator Brand |

Main Control Valve (Multi-Way Valve) Configuration |

Cost-Performance Highlights (Advantages Easy for Beginners to Understand) |

Applicable Scenarios |

Reference Service Life (Heavy-Duty Condition) |

Replacement Cost |

|

International |

Caterpillar |

Self-developed Cat® Multi-Way Valve (with pressure compensation function) |

Stable pressure (no stalling when digging hard rock), smooth simultaneous multi-movements, low failure rate |

Mining crushing, large-scale infrastructure |

6,000-8,000 hours |

50,000-80,000 yuan (7,140-11,430)/unit |

|

Komatsu |

Self-developed PC Series Multi-Way Valve (with flow adjustment) |

Precise movements (e.g., stable boom lifting/lowering when trimming slopes), low fuel consumption (6% less than similar products) |

Municipal engineering, farmland transformation |

5,000-7,000 hours |

40,000-60,000 yuan (5,710-8,570)/unit |

|

|

Volvo |

Bosch Rexroth Multi-Way Valve |

Strong low-temperature adaptability (smooth operation at -30°C), low noise (≤72 decibels during operation) |

Urban demolition, winter construction in northern regions |

5,500-7,500 hours |

45,000-70,000 yuan (6,430-10,000)/unit |

|

|

Domestic |

Sany |

Self-developed SY Series Multi-Way Valve (with anti-contamination design) |

Low price (15,000-25,000 yuan (2,140-3,570)/unit), easy access to spare parts, many domestic maintenance outlets |

Rural house renovation, small construction sites |

4,000-6,000 hours |

15,000-25,000 yuan (2,140-3,570)/unit |

|

XCMG |

XCMG Self-developed Multi-Way Valve (with efficient heat dissipation) |

High-temperature resistance (hydraulic oil temperature not easily exceeding 60°C during summer operation), can withstand medium-heavy workloads |

Municipal repairs, mountain road construction |

4,500-6,500 hours |

18,000-30,000 yuan (2,570-4,290)/unit |

|

|

Liugong |

Liugong Multi-Way Valve (with anti-leakage seal) |

Good sealing performance (not easy to leak oil), strong durability, suitable for dusty environments such as gravel yards |

Gravel yard operations, roadbed construction |

4,000-5,500 hours |

16,000-28,000 yuan (2,290-4,000)/unit |

IV. Main Control Valve Maintenance: Do These 4 Things to Extend Service Life by 3 Years!

1. Regularly Replace Hydraulic Oil and Filters: Provide Clean Oil for the "Control Center"

• Hydraulic Oil: Replace it according to the instructions—every 2,000 hours for heavy-duty conditions (e.g., mining operations) and every 3,000 hours for light-duty conditions (e.g., municipal operations). Keep the oil level between "MIN" and "MAX" to avoid oil shortage;

• Filters: When replacing hydraulic oil, you must replace the "main hydraulic oil filter" and "return oil filter" at the same time. Check the filters every 500 hours during daily use, and replace them in time if they are dirty to prevent impurities from entering the main control valve.

2. Operate the Control Lever Smoothly: Avoid Violent Operation and Pressure Stalling

• Push and release the control lever slowly to ensure smooth movement of the spool and avoid sudden force;

• When digging hard soil or rock is blocked, avoid forced pressure stalling. Instead, move back and adjust the angle before trying again to prevent the main control valve from enduring high pressure for a long time.

3. Regularly Inspect 2 Key Parts: Detect Hidden Troubles Early

• Leakage Inspection: Check the oil pipe interfaces and spool seals of the main control valve every week to see if there is hydraulic oil leakage (leaked oil will form oil stains around the valve body). If leakage is found, replace the seals in time to avoid excessive oil loss;

• Temperature Inspection: When working in summer, touch the valve body of the main control valve with your hand (be careful to avoid scalding). If it feels "too hot" (temperature exceeding 60°C), stop the machine immediately to check the hydraulic oil radiator and clean the dust to prevent valve body deformation.

4. Maintenance During Long-Term Idleness: Prevent Component Aging

If the excavator is idle for more than 1 month, start it every 10 days and operate all control levers (repeat each movement 3-5 times) to circulate the hydraulic oil in the main control valve, avoiding spool jamming and seal aging.

V. Conclusion

As the "motion control center" of the excavator, beginners need to remember 3 core points about the main control valve:

1. Avoid Damage Risks: Eliminate 5 taboos such as hydraulic oil contamination, violent operation of the control lever, and high-temperature operation to prevent the main control valve from being scrapped in advance;

2. Choose the Right Model: Prioritize international brands (such as Caterpillar and Komatsu) for heavy-duty operations, and domestic brands (such as Sany Heavy Industry and XCMG) for light-duty operations, balancing cost-performance and practicality;

3. Insist on Daily Maintenance: Regularly replace oil and filters, operate smoothly, and inspect for hidden troubles in a timely manner. Doing these 4 things well can extend the service life of the main control valve by 3 years and reduce maintenance costs.

About SPARKLING MACHINERY:

- Founded in 2013, SPARKLING focuses on high-quality excavator parts across hydraulics, undercarriage, engines and electrical systems. We prioritize stability, precision and continuous service, offering worldwide distribution, tailored solutions and strict QC to help customers reduce cost and increase uptime.

Get In Touch:

- Replace your failing ECU confidently. Contact SPARKLING for pricing, lead time, and technical support — restore optimal machine control quickly and reliably.

Hyundai & Doosan Wheel Excavator Parts Supplier | Complete Range of Replacement Components

Kubota Error Codes: A Comprehensive Diagnostic & Reset Manual

How to Resolve Error Code P0037: A Comprehensive Guide

The Definitive Guide to Excavator Diesel Engine Turbochargers: Maximizing Power with High-Performance Forced-Induction Core Components

The Ultimate Guide to Excavator Parts: Anatomy, Functionality & Future Trends for 2026

faq

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

CATERPILLAR EXCAVATOR 349 541-1387 5411387 OIL COOLER ASSY CHINA MADE

CATERPILLAR EXCAVATOR 349 541-1387 5411387 OIL COOLER ASSY CHINA MADE

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Temperature sensor 14509344 16688307 For Volvo EC210B EC290C L60F L70F

Temperature sensor 14509344 16688307 For Volvo EC210B EC290C L60F L70F

KOBELCO EXCAVATOR SK115SR SK135SR YV22E00001F8 YV22E00001F5 CPU CONTROLLER UNIT ORIGINAL

KOBELCO EXCAVATOR SK115SR SK135SR YV22E00001F8 YV22E00001F5 CPU CONTROLLER UNIT ORIGINAL

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX70 ZX85US-3 ZX75US-3 4446258 CYL;BUCKET SPARKLING MACHINERY

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX70 ZX85US-3 ZX75US-3 4446258 CYL;BUCKET SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 140M 330D 336D 336D2 265-1401 PISTON SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 140M 330D 336D 336D2 265-1401 PISTON SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 551-0841+524-5566+6V-5589 PISTON KIT SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 551-0841+524-5566+6V-5589 PISTON KIT SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW C9 CX31-C9I TH31-E61 250-7701 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW C9 CX31-C9I TH31-E61 250-7701 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 350 594-7756 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 350 594-7756 TURBO SPARKLING MACHINERYGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879