Hydraulic Pump Selection Guide: 7 Core Essentials + Cost-Effective Options

The hydraulic pump is the "power heart" of an excavator. Choosing the wrong one will lead to problems such as insufficient power, soaring fuel consumption, and frequent failures, and may even cause collateral damage to the hydraulic system. Referring to professional purchasing logic, this article sorts out 7 key selection essentials, combined with brand comparisons, scenario suggestions, and daily inspection lists, helping you accurately avoid pitfalls and select a suitable and durable hydraulic pump!

I. 7 Core Essentials for Selecting a Hydraulic Pump

1. Match Machine Parameters: Prioritize checking the excavator's tonnage and engine power. Ensure the hydraulic pump's rated pressure (medium-high pressure of 16-32MPa is recommended) and displacement are consistent with the original factory specifications to avoid "underpowered operation" or poor adaptability.

2. Confirm Pressure Level: Select pressure based on working conditions—medium pressure (8-16MPa) for light conditions (municipal engineering), high pressure (16-32MPa) for heavy conditions (mine crushing), and ultra-high pressure (>32MPa) only for extreme heavy-load scenarios.

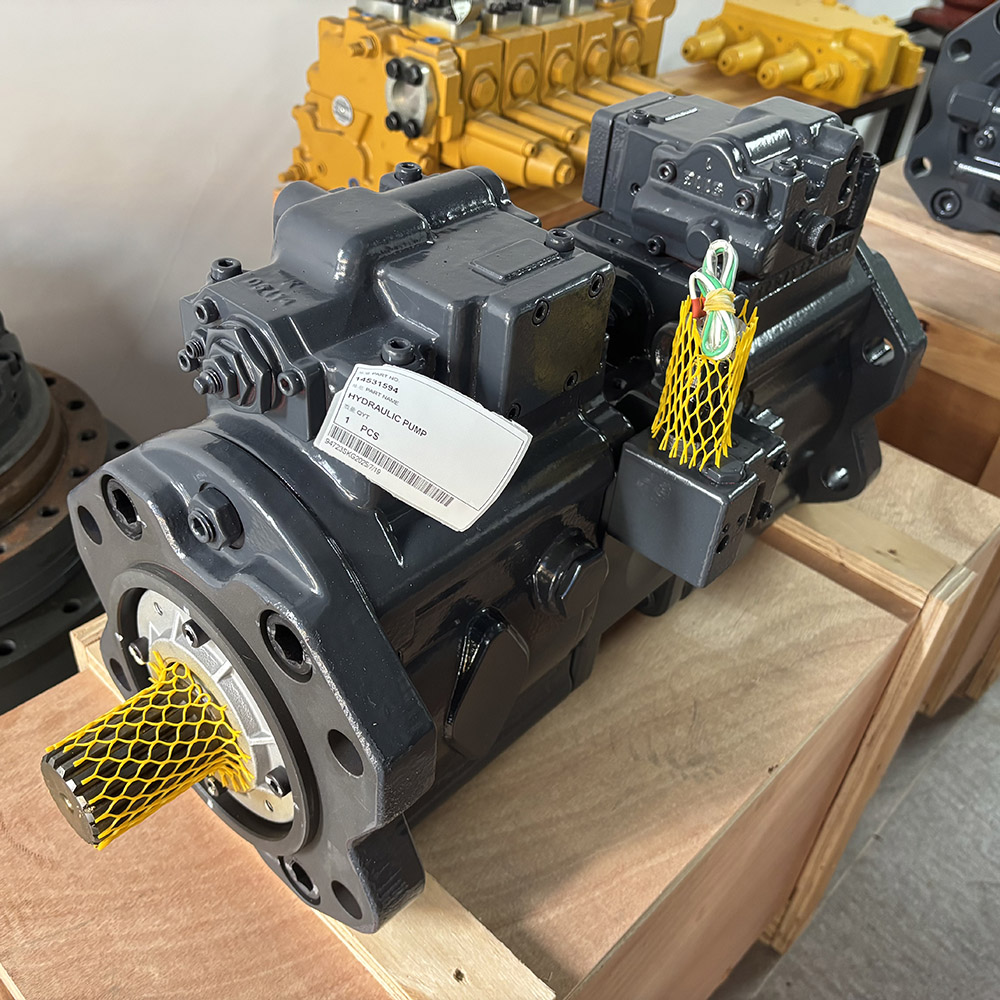

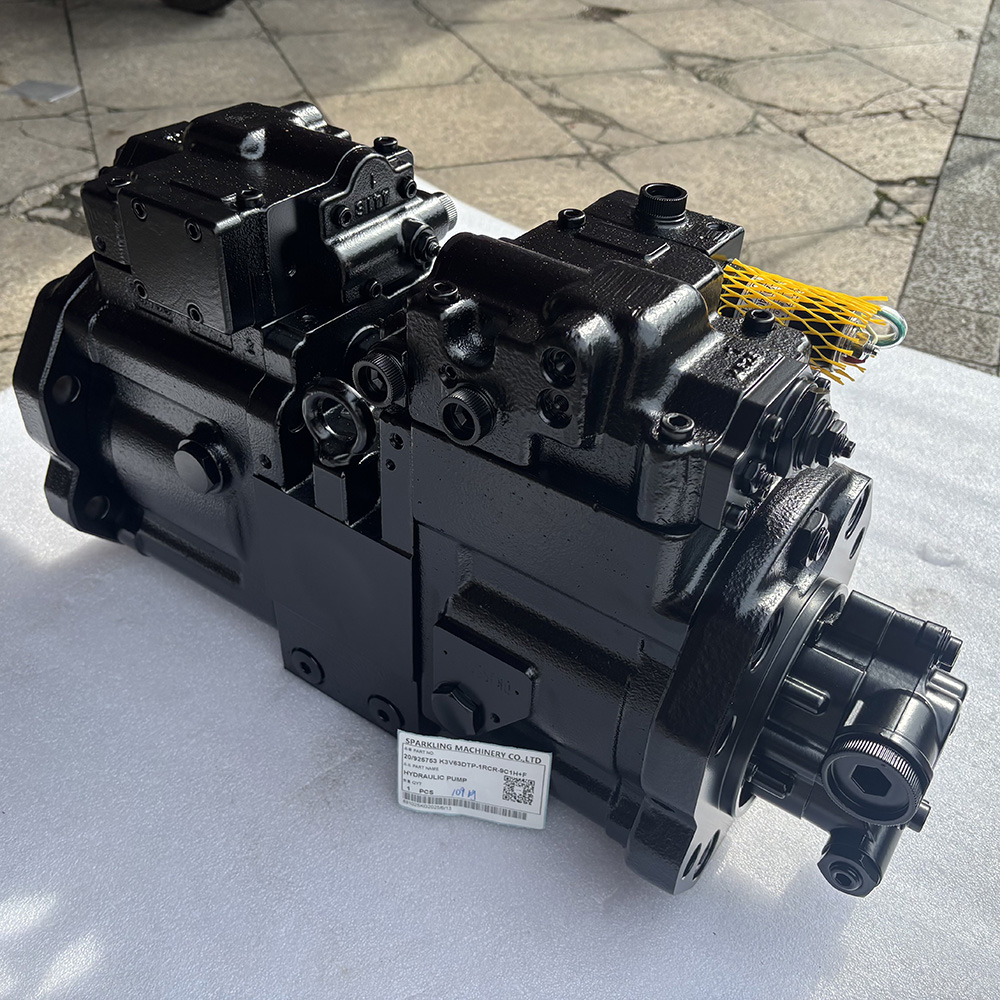

3. Inspect Core Materials: High-quality hydraulic pumps use high-strength alloy steel for the pump body, wear-resistant materials for bearings and seals, with a smooth surface free of burrs and cracks. Quality can be initially judged by appearance.

4. Test Operating Status: A normal hydraulic pump operates with low noise, no metal friction or hissing sounds; no obvious leakage after startup, and the outlet pressure is stable within the rated range, which can be verified by on-site pressure gauge measurement.

5. Verify Warranty Service: Prioritize products with a 3-12 month warranty. OEM parts usually come with a 6-12 month warranty, while top aftermarket brands offer 3-6 months. Be sure to request warranty certificates.

6. Adapt to Working Speed: Ensure the hydraulic pump's rated speed matches the excavator's engine speed (common rated speed: 1500-2500r/min). Mismatched speeds will reduce efficiency and shorten service life.

7. Choose Formal Channels: Purchase through brand authorized stores or regular distributors to avoid unbranded products—low-quality hydraulic pumps may cause hydraulic oil leakage and pump body cracking due to poor sealing and weak materials.

II. Cost-Effectiveness Comparison of Popular Hydraulic Pump Brands

|

Brand Type |

Representative Brands |

Core Advantages |

Applicable Working Conditions |

Rated Pressure |

Reference Price (for 20-ton Excavator) |

Warranty Period |

|

OEM |

Kawasaki |

Original factory adaptation, high-quality materials, stable pressure |

Heavy conditions, large-scale infrastructure |

25-32MPa |

USD 3,437.5 - USD 5,500 |

12 months |

|

OEM |

Rexroth Bosch |

High efficiency, low noise, strong durability |

Mine crushing, extreme environments |

28-32MPa |

USD 3,850 - USD 6,187.5 |

12 months |

|

OEM |

Caterpillar |

Perfect matching with own models, comprehensive after-sales service |

Exclusive for Caterpillar excavators, heavy conditions |

26-30MPa |

USD 4,125 - USD 6,875 |

12 months |

|

AFTERMARKET |

Sany(Aftermarket) |

High cost-effectiveness, wide adaptability, easy access to spare parts |

Light to medium conditions, municipal engineering |

20-25MPa |

USD 1,375 - USD 2,475 |

6 months |

|

AFTERMARKET |

XCMG (Aftermarket) |

Quality close to OEM, affordable price |

Rural renovation, site leveling |

20-25MPa |

USD 1,237.5 - USD 2,200 |

6 months |

III. Selection Suggestions for Different Scenarios

1. Heavy-Duty Operations: For high-intensity scenarios such as mining and crushing, directly select OEM hydraulic pumps like Kawasaki and Rexroth Bosch. Their high rated pressure and durable materials can avoid frequent failure downtime (a single day of downtime results in losses exceeding USD 1,375).

2. Light to Medium-Duty Operations: For operations such as municipal engineering and rural renovation, choose top aftermarket brands like Sany and XCMG. The price is only 40%-60% of OEM, which can meet daily operation needs.

3. Old Machine Maintenance: When original parts are discontinued or overpriced, select professional third-party brands like Wuxi Youli. They offer strong adaptability and high cost-effectiveness, and can be installed without major modifications.

4. Budget-Limited Scenarios: For short-term use or transition with second-hand excavators, reliable aftermarket brands can be chosen. However, regular pressure and leakage checks are required to avoid hidden dangers.

IV. Daily Hydraulic Pump Inspection Checklist (Daily/Weekly Must-Do)

|

Inspection Cycle |

Inspection Items |

Inspection Content & Standards |

Abnormal Handling Methods |

|

Before Daily Operation |

Appearance & Leakage Inspection |

No cracks or deformation on the pump body surface; no hydraulic oil leakage at seals (shaft ends, interfaces); no loose oil pipe joints |

Replace seals or tighten joints for leakage; immediately shut down and contact maintenance for pump body cracks |

|

Before Daily Operation |

Hydraulic Oil Level & Quality |

Oil level between "MIN-MAX" of the oil tank; oil is clear without impurities, foam, or burnt odor |

Add the same type of hydraulic oil if the level is insufficient; fully replace oil and clean filters if oil quality deteriorates |

|

During Operation (Real-Time Observation) |

Operating Noise & Vibration |

Operating noise ≤75 decibels, no metal friction or impact sounds; small pump body vibration amplitude, no obvious jitter |

Shut down for inspection if noise/vibration is abnormal (may be due to bearing wear or internal part damage), requiring disassembly and maintenance |

|

During Operation (Real-Time Observation) |

Outlet Pressure Monitoring |

Check via pressure gauge; pressure is stable within the rated range (±0.5MPa) without large fluctuations |

Inspect relief valve or pump internal part wear if pressure fluctuates significantly; adjust or replace damaged parts in time |

|

Weekly Inspection |

Oil Temperature & Heat Dissipation |

Hydraulic oil temperature maintains 45-55℃ during operation; no blockage in the radiator, fan operates normally |

Clean the radiator and check the temperature control valve if oil temperature is too high; repair fan faults promptly to avoid pump body damage due to high temperature |

|

Weekly Inspection |

Connecting Bolts & Fixings |

No loose pump body fixing bolts or coupling bolts; no displacement or deformation at connection parts |

Tighten loose bolts according to specified torque (reference: 80-120N・m); replace deformed parts |

|

Monthly Inspection |

Filter Cleanliness |

No blockage in hydraulic pump inlet and return filters, no excessive impurity accumulation on the surface |

Replace blocked filters immediately; if blockage occurs frequently, check hydraulic oil cleanliness or internal tank impurities |

About SPARKLING MACHINERY:

- Founded in 2013, SPARKLING focuses on high-quality excavator parts across hydraulics, undercarriage, engines and electrical systems. We prioritize stability, precision and continuous service, offering worldwide distribution, tailored solutions and strict QC to help customers reduce cost and increase uptime.

Get In Touch:

- Replace your failing ECU confidently. Contact SPARKLING for pricing, lead time, and technical support — restore optimal machine control quickly and reliably.

Fixing Oil Cooler Leaks in Heavy Machinery: A Complete Guide

Engine Oil Leak Repair Costs: A Comprehensive Guide

Hyundai & Doosan Wheel Excavator Parts Supplier | Complete Range of Replacement Components

Kubota Error Codes: A Comprehensive Diagnostic & Reset Manual

How to Resolve Error Code P0037: A Comprehensive Guide

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

CATERPILLAR EXCAVATOR 349 541-1387 5411387 OIL COOLER ASSY CHINA MADE

CATERPILLAR EXCAVATOR 349 541-1387 5411387 OIL COOLER ASSY CHINA MADE

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Temperature sensor 14509344 16688307 For Volvo EC210B EC290C L60F L70F

Temperature sensor 14509344 16688307 For Volvo EC210B EC290C L60F L70F

KOBELCO EXCAVATOR SK115SR SK135SR YV22E00001F8 YV22E00001F5 CPU CONTROLLER UNIT ORIGINAL

KOBELCO EXCAVATOR SK115SR SK135SR YV22E00001F8 YV22E00001F5 CPU CONTROLLER UNIT ORIGINAL

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX70 ZX85US-3 ZX75US-3 4446258 CYL;BUCKET SPARKLING MACHINERY

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX70 ZX85US-3 ZX75US-3 4446258 CYL;BUCKET SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 140M 330D 336D 336D2 265-1401 PISTON SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 140M 330D 336D 336D2 265-1401 PISTON SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 551-0841+524-5566+6V-5589 PISTON KIT SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 551-0841+524-5566+6V-5589 PISTON KIT SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW C9 CX31-C9I TH31-E61 250-7701 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW C9 CX31-C9I TH31-E61 250-7701 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 350 594-7756 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 350 594-7756 TURBO SPARKLING MACHINERYGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879