The "Rotary Joint" of Excavators! A Complete Guide to Slewing Ring (Large Turntable): Structure, Selection & Maintenance

When operating an excavator, have you ever encountered issues like the machine body failing to rotate, abnormal noises during rotation, or automatic "slipping rotation" when working on slopes? Most of these problems stem from the "large turntable" — technically known as the slewing ring. As the core component connecting the upper and lower machine bodies, it enables the excavator to adjust its working direction; without it, the machine cannot change the direction of operation at all.

However, many operators neglect its maintenance and only repair it when the raceway is worn out, which not only costs tens of thousands of dollars but also results in days of downtime. This article thoroughly explains its structure, risk factors, brand comparisons, and maintenance methods in plain language — even beginners can understand it, helping the slewing ring rotate smoothly and last longer!

- I. Understanding the Slewing Ring (Large Turntable): The "Rotary Core" of the Excavator

- 1. Structure: 3 Key Components Support "Rotation + Load - Bearing"

- 2. Core Principle: "Rolling Friction" Enables Flexible Rotation

- 3. Importance: Without It, the Excavator "Can’t Turn Around"

- II. 5 Things the Slewing Ring Fears the Most!

- III. Cost - Effectiveness Comparison of Slewing Rings from Domestic and Foreign Excavator Brands

- IV. 5 - Step Maintenance for the Slewing Ring

- V. Summary

I. Understanding the Slewing Ring (Large Turntable): The "Rotary Core" of the Excavator

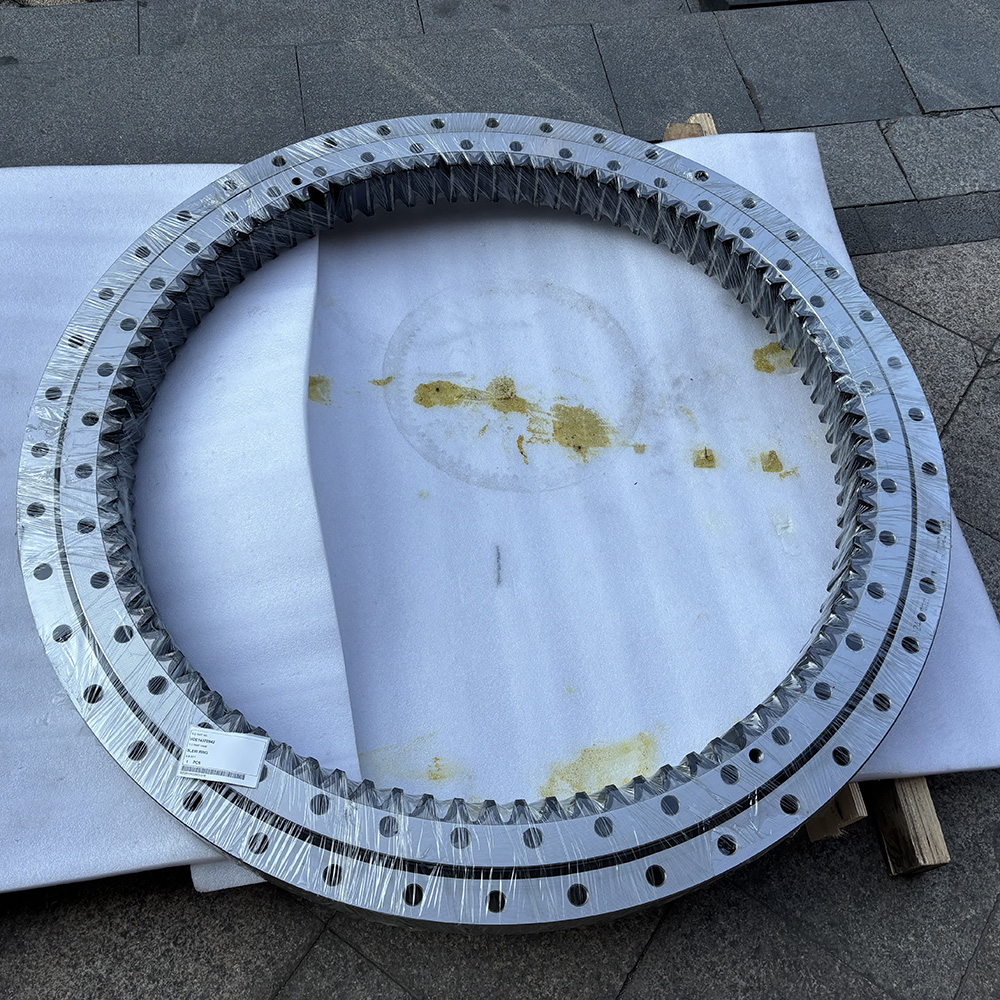

1. Structure: 3 Key Components Support "Rotation + Load - Bearing"

• Inner Ring & Outer Ring: Circular rings made of high - strength alloy steel. The inner ring is connected to the upper machine body (cab, boom), while the outer ring is attached to the chassis. The inner side is equipped with a "raceway" for placing rolling elements;

• Rolling Elements: Steel balls or rollers (about 50 - 80 pieces for a 20 - ton excavator). Their surfaces are quenched (hardness HRC55 - 60) to reduce friction;

• Cage & Seals: The cage separates the rolling elements to prevent friction between them. The seals (rubber sealing rings) prevent impurities and water from entering and retain lubricating grease.

2. Core Principle: "Rolling Friction" Enables Flexible Rotation

The swing motor drives a small gear, which meshes with the inner or outer ring of the slewing ring. The rolling elements in the raceway roll, allowing the upper machine body to rotate 360 degrees. At the same time, it transfers the weight of the upper body to the chassis, realizing the dual functions of "rotation + load - bearing". It can be compared to an "office chair swivel base".

3. Importance: Without It, the Excavator "Can’t Turn Around"

• Foundation for Rotation: Without the slewing ring, the bucket can only operate in one direction, reducing work efficiency by 60%;

• Key to Load - Bearing: It bears the weight of the upper body (10 - 12 tons). If damaged, the machine body may tilt;

• Expensive Maintenance: An imported slewing ring costs USD 2,750 - USD 6,875. Replacing it requires hoisting the machine body, resulting in 3 - 5 days of downtime, and the downtime loss is even higher than the maintenance cost.

II. 5 Things the Slewing Ring Fears the Most!

1. Lack of Lubricating Grease: Dry friction occurs between the raceway and rolling elements, causing scratches and abnormal noises. The repair or replacement cost ranges from USD 137.5 - USD 6,875;

2. Impurities & Water Ingress: Cracked seals allow gravel and water to enter the raceway, leading to wear and rust and accelerating damage;

3. Unilateral Load - Bearing: Long - term one - sided operation causes "uneven wear" of the raceway, reducing its service life by half;

4. Sudden Acceleration / Emergency Stop: Impact loads cause rolling elements to break and raceways to deform, resulting in machine body jamming;

5. Overload Operation: Installing overweight equipment or digging excessive materials exceeds the load - bearing limit, leading to raceway cracking.

III. Cost - Effectiveness Comparison of Slewing Rings from Domestic and Foreign Excavator Brands

|

Excavator Brand |

Configuration Highlights |

Suitable Scenarios |

Service Life Under Heavy Working Conditions (20 - ton Excavator) |

Replacement Cost (Including Labor) |

|

Caterpillar |

Outer ring made of 50Mn alloy steel (quenching depth 5 - 8mm), HRC60 steel balls, oil - resistant seals |

Mine crushing, large - scale infrastructure construction |

8,000 - 10,000 hours |

USD 5,500 - USD 11,000 |

|

Komatsu |

Polished raceway, roller load - bearing, dust - proof seals |

Municipal engineering, farmland transformation |

7,000 - 9,000 hours |

USD 4,787.5 - USD 9,625 |

|

Volvo |

Double quenching, anti - corrosion rolling elements, low - temperature resistant seals (-30℃) |

Urban demolition, winter construction in northern regions |

7,500 - 9,500 hours |

USD 5,225 - USD 10,125 |

|

Sany |

Outer ring made of 45Mn steel, cost - effective steel balls, easy - to - replace seals |

Rural house renovation, small - scale construction sites |

5,000 - 7,000 hours |

USD 2,062.5 - USD 4,125 |

|

XCMG |

Inner ring with reinforcing ribs, roller load - bearing, anti - aging seals (2 - year service life) |

Municipal repairs, mountain road construction |

5,500 - 7,500 hours |

USD 2,475 - USD 4,787.5 |

|

Liugong |

Outer ring made of ordinary alloy steel, basic steel balls, affordable price |

Gravel yard operations, roadbed construction |

5,000 - 6,500 hours |

USD 1,650 - USD 3,850 |

IV. 5 - Step Maintenance for the Slewing Ring

1. Add Grease on Time: Under heavy working conditions (e.g., mines), add "lithium - based grease" every 100 - 200 hours; under light working conditions (e.g., municipal engineering), add it every 300 - 500 hours until the grease overflows;

2. Inspect Seals: Check weekly if the seals are cracked, and after rain, check for water leakage. Replace damaged seals promptly (domestic seals cost USD 27.5 - USD 68.75 per set);

3. Avoid Unbalanced Loads & Overloads: Alternate operations on both sides of the machine, do not install overweight equipment, and do not dig excessive materials;

4. Operate Smoothly: Push and release the swing control lever slowly, avoiding sudden acceleration and emergency stops;

5. Protection During Idleness: If the excavator is idle for more than 1 month, rotate the slewing ring 360 degrees and replenish grease monthly. Cover it with a waterproof cloth when parked outdoors.

V. Summary

The slewing ring is the "rotary joint" of the excavator. There are 3 key points to remember: understand its structure (inner ring/outer ring + rolling elements), avoid 5 types of risks (lack of grease, impurity ingress, etc.), and conduct maintenance in 5 steps. Proper maintenance of the slewing ring ensures smooth rotation of the excavator, fewer failures, reduced maintenance costs, and improved efficiency — truly "saving big money with small maintenance"!

About SPARKLING MACHINERY:

- Founded in 2013, SPARKLING focuses on high-quality excavator parts across hydraulics, undercarriage, engines and electrical systems. We prioritize stability, precision and continuous service, offering worldwide distribution, tailored solutions and strict QC to help customers reduce cost and increase uptime.

Get In Touch:

- Replace your failing ECU confidently. Contact SPARKLING for pricing, lead time, and technical support — restore optimal machine control quickly and reliably.

Hyundai & Doosan Wheel Excavator Parts Supplier | Complete Range of Replacement Components

Kubota Error Codes: A Comprehensive Diagnostic & Reset Manual

How to Resolve Error Code P0037: A Comprehensive Guide

The Definitive Guide to Excavator Diesel Engine Turbochargers: Maximizing Power with High-Performance Forced-Induction Core Components

The Ultimate Guide to Excavator Parts: Anatomy, Functionality & Future Trends for 2026

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX70 ZX85US-3 ZX75US-3 4446258 CYL;BUCKET SPARKLING MACHINERY

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX70 ZX85US-3 ZX75US-3 4446258 CYL;BUCKET SPARKLING MACHINERY

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX110 ZX130H ZX130K ZX120 4469057 CORE SPARKLING MACHINERY

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX110 ZX130H ZX130K ZX120 4469057 CORE SPARKLING MACHINERY

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW DL200 DL250 DL300 DL400 2920-6112 HEATER CORE SPARKLING MACHINERY

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW DL200 DL250 DL300 DL400 2920-6112 HEATER CORE SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 307D 312D 313D 319D 320D 245-7833 HEATER CORE SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 307D 312D 313D 319D 320D 245-7833 HEATER CORE SPARKLING MACHINERY

JCB HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 25/221094 25/222891 PILOT VALVE SPARKLING MACHINERY

JCB HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 25/221094 25/222891 PILOT VALVE SPARKLING MACHINERY

Komatsu HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 14X-12-11103 DAMPER SPARKLING MACHINERY

Komatsu HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 14X-12-11103 DAMPER SPARKLING MACHINERY

XCMG HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 4110002549009 TENSION PULLEY SPARKLING MACHINERY

XCMG HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 4110002549009 TENSION PULLEY SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 416F 420F 422F 428F 430F 343-5643 AIR CLEANER SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 416F 420F 422F 428F 430F 343-5643 AIR CLEANER SPARKLING MACHINERYGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879