Why Can a Tens-of-Tons Excavator Spin Gracefully? Swing System (Reducer + Motor) Principle, Brand Comparison & Maintenance Guide

Have you ever watched a ballerina spin elegantly on her toes? But did you know that an excavator, weighing tens of tons, can also spin 360° smoothly, align precisely for dumping, and even "turn nimbly" in tight construction sites—just like a ballerina? However, if its swing system malfunctions, this heavy machine turns into a "clumsy giant": it spins slowly, shakes violently, takes an extra 2 minutes to unload a truck, and costs over $2,800 to repair!

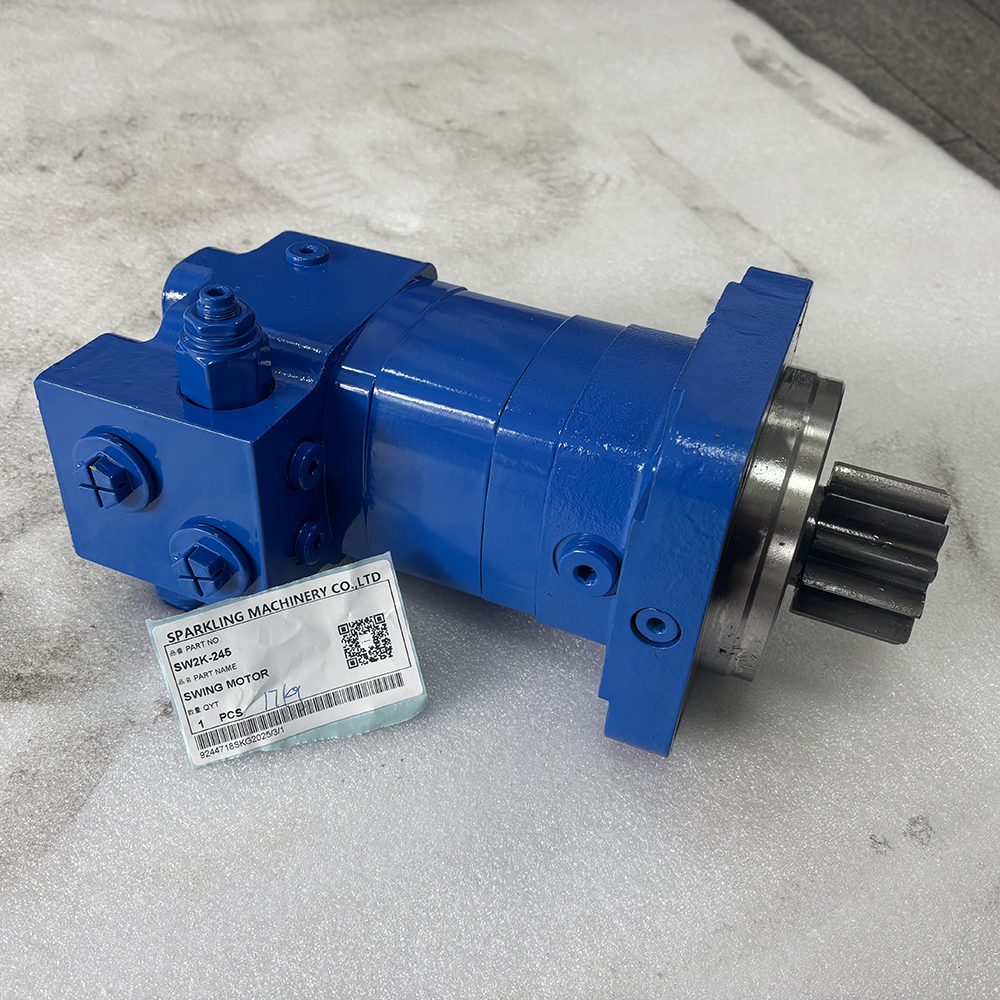

In fact, the core behind an excavator’s "elegant spins" is the combination of the swing reducer and swing motor—known together as the "swing system". Many operators only know how to use the excavator but don’t understand the system’s structure, how to switch between high and low gears, or how to maintain it properly. This article uses plain language to break down this "spin secret": from its structure and gear principles to brand comparisons and maintenance tips. Even beginners can easily learn, ensuring your excavator keeps spinning "smoothly and steadily"!

- I. Swing Reducer + Swing Motor: The "Spin Partners" of an Excavator—No Them, No Graceful Spins!

- 1. Structure: Two "Partners" with Clear Roles—Each Masters a Spin Key

- 2. Core Principle: High/Low Gears—Make Spins Fast AND Elegant

- 3. Importance: Without It, the Excavator Becomes a "Clumsy Scrap Heap"—Spins Fail Completely

- II. Don’t Ruin Your Excavator’s "Elegant Spins"! Avoid These 5 Mistakes

- 1. Jerky Joystick Moves: "Sudden Brakes/Accelerations" Damage Gears

- 2. Heavy Loads in High Gear: "Insufficient Torque" Ruins the Motor

- 3. Contaminated Hydraulic Oil: "Jammed Spins" Wear Parts

- 4. Not Locking on Slopes: "Unstable Spins" Age Gears

- 5. Hitting Obstacles While Spinning: "Out-of-Control Spins" Damage Components

- III. Swing System Comparison: Domestic vs. International Brands—Choose Right for Elegant, Durable Spins!

- IV. Maintenance Tips: 5 Steps to Keep Your Excavator Spinning Gracefully for 3 More Years

- 1. "Gentle" Operation: No Sudden Brakes or Jerky Spins

- 2. "Clean" Oil Changes: Feed the Swing System Clean Oil

- 3. Weekly "Checks": Catch Spin Issues Early

- 4. Avoid "Collisions": Check Surroundings Before Spinning

- 5. "Spin" During Long Downtime: Don’t Let the System Rust

- V. Conclusion

I. Swing Reducer + Swing Motor: The "Spin Partners" of an Excavator—No Them, No Graceful Spins!

The reason a tens-of-tons excavator can spin as flexibly as a ballerina lies entirely in this "golden pair": the swing reducer and swing motor. Simply put, the swing motor is the "power source for spinning" (it makes the upper structure turn), while the swing reducer is the "spin controller" (it ensures spins are stable, accurate, and fast). For beginners, just remember these 3 key points:

1. Structure: Two "Partners" with Clear Roles—Each Masters a Spin Key

• Swing Motor: Acts like a "small hydraulic engine", with core components including "pistons, a cylinder block, and an output shaft". High-pressure hydraulic oil rushes into the cylinder block, pushing the pistons back and forth to drive the output shaft rotation. It’s like a ballerina’s "feet"—sustained power is needed to keep spinning. Without it, the excavator’s upper structure would be a "fixed, immovable block".

• Swing Reducer: Resembles a "gear adjustment box", filled with gears of different sizes (e.g., planetary gears, sun gears—beginners don’t need to memorize the names). The motor’s output shaft connects to the reducer; through gear meshing, the reducer converts the motor’s "high-speed, low-torque" power into "low-speed, high-torque" power. For example, if the motor spins 10 times, the reducer outputs only 1 spin—but with 10 times more force. This not only keeps the upper structure spinning smoothly but also controls the rotation angle precisely, avoiding messy, unstable shakes.

2. Core Principle: High/Low Gears—Make Spins Fast AND Elegant

Just like a ballerina has "fast spins" and "slow toe spins", an excavator’s swing system has "high gear" and "low gear". Using the right gear for different scenarios doubles work efficiency:

• High Gear (Fast Gear): Ideal for "quick position adjustments"

Principle: Inside the reducer, "small gears drive large gears"—this increases rotation speed but reduces torque. It’s used when you need to quickly spin the empty upper structure (e.g., aligning with a truck after digging a bucket of soil). In high gear, the excavator spins a full circle in just 8–10 seconds—half the time of low gear. It’s like a ballerina’s "fast spins": no slow adjustments needed, boosting efficiency.

Scenarios: Adjusting the working angle with an empty bucket, or quickly spinning to dump materials. Using high gear saves 10–20 seconds per cycle, allowing you to unload 10 more trucks a day.

• Low Gear (Slow Gear): Ideal for "precision spins"

Principle: Inside the reducer, "large gears drive small gears"—this slows down rotation but increases torque. It’s used when the bucket is full (e.g., carrying soil or breaking rocks) and precise alignment is needed. In low gear, the excavator shakes less than 2cm during spins, so no materials spill. It’s like a ballerina’s "slow toe spins": every movement is accurate, with no mistakes.

Scenarios: Mining crushing, deep foundation excavation—low gear ensures safety and precision during heavy-load spins.

3. Importance: Without It, the Excavator Becomes a "Clumsy Scrap Heap"—Spins Fail Completely

• Spin "Elegance" Depends on It: A well-functioning swing system lets the excavator spin fast and steady. For example, during municipal pipeline repairs, it can align with the trench precisely without repeated adjustments. If the system fails, slow, shaky spins add 2 minutes per truck—costing you 5–8 fewer loads a day.

• Safety Relies on It: When working on slopes, the swing system has a "locking function"—like a ballerina’s stable center of gravity. It keeps the upper structure fixed, preventing accidental sliding down the slope. A broken lock can cause sudden spins, leading to spilled materials or even safety accidents.

• Repair Costs Are Sky-High: An imported swing system (motor + reducer) costs 11,200–14,000, while a domestic one costs 2,800–4,200. Repairs also require disassembling the upper structure and lifting the chassis, leading to at least 3 days of downtime. Combined with lost work costs, a single repair can cost 1,400–2,800—making it the "unaffordable core component".

II. Don’t Ruin Your Excavator’s "Elegant Spins"! Avoid These 5 Mistakes

To keep your excavator spinning gracefully, steer clear of these 5 mistakes—they’re like "tripping hazards for ballerinas" and will damage the swing system quickly:

1. Jerky Joystick Moves: "Sudden Brakes/Accelerations" Damage Gears

Many operators, in a hurry, push the swing joystick all the way forward—making the excavator spin suddenly, then slam on the brakes. This is like a ballerina stopping abruptly mid-spin: she loses balance, and the excavator’s reducer gears "collide hard". Minor damage wears down gear teeth; severe damage breaks gears entirely. Soon, you’ll hear a "clunking sound" during spins, and eventually, the system will stop working.

2. Heavy Loads in High Gear: "Insufficient Torque" Ruins the Motor

Using high gear when the bucket is full (e.g., carrying 3 tons of soil) is a big mistake. High gear has low torque and can’t handle heavy loads, so the motor is forced to "overwork". Its internal pistons get deformed by high hydraulic pressure—like a ballerina trying to spin with a heavy weight: she’ll fall. Soon, the motor will leak oil and lose power, costing 1,400–2,800 to repair.

3. Contaminated Hydraulic Oil: "Jammed Spins" Wear Parts

The swing motor relies on clean hydraulic oil for lubrication and power. If dust or metal shavings mix into the oil (e.g., not replacing the filter on time), it’s like "sand in a ballerina’s shoes". The contaminants scratch the motor’s pistons and cylinder block, causing oil leaks. Spins will get slower and shakier over time, and replacing all seals costs 700–1,120.

4. Not Locking on Slopes: "Unstable Spins" Age Gears

When parking on a slope, always activate the "swing lock" (some excavators lock automatically; others need a manual button). Without it, gravity will pull the upper structure toward the slope, and the reducer gears will be forced to "hold it in place"—like a ballerina balancing on tiptoes on a slope: she must strain to stay steady. Over time, the gears wear out, the lock fails, and the upper structure can’t stay fixed.

5. Hitting Obstacles While Spinning: "Out-of-Control Spins" Damage Components

If you spin without checking your surroundings and hit a utility pole or truck, the impact directly damages the swing system. It can bend reducer gears or deform the swing bearing—like a ballerina crashing mid-spin: she gets hurt. Replacing the entire system costs 4,200–7,000, plus a week of downtime.

III. Swing System Comparison: Domestic vs. International Brands—Choose Right for Elegant, Durable Spins!

|

Brand Type |

Excavator Brand |

Swing System Configuration (Motor + Reducer) |

Spin Performance (Elegance + Efficiency) |

Cost-Effectiveness Highlights |

Suitable Scenarios |

Estimated Lifespan (Heavy-Duty) |

|

International |

Caterpillar |

In-house Cat® Swing Motor + Planetary Reducer |

High gear: 8s/full spin; Low gear: ≤2cm shake (ultra-stable) |

Overload-resistant; spins gracefully even in mining/rock work; low failure rate |

Mining crushing, large-scale infrastructure |

6,000–8,000 hours |

|

Komatsu |

In-house PC Series Motor + Sumitomo Reducer |

High gear: smooth (no shakes); Low gear: handles 5-ton loads (precise spins) |

Fuel-efficient (5% less than peers); no wasted fuel during spins |

Municipal projects, port loading |

5,000–7,000 hours |

|

|

Volvo |

Bosch Rexroth Motor + Volvo Reducer |

High gear: ≤70dB (quiet); spins gracefully even at -30℃ |

Cold-resistant; quiet for urban work (no noise complaints) |

Urban demolition, winter construction (Northern China) |

5,500–7,500 hours |

|

|

Domestic |

Sany Heavy Industry |

In-house SY Series Motor + Jiangsu Tailong Reducer |

High gear: 10s/full spin; Low gear: performance close to international brands |

Affordable (2,800–4,200/set); easy to find spare parts; convenient repairs |

Rural house renovation, small construction sites |

4,000–6,000 hours |

|

XCMG |

XCMG Self-Developed Motor + German ZF Reducer |

High gear: 9s/full spin; Low gear: handles 4-ton loads (efficient spins) |

Cost-effective; handles medium-heavy work gracefully; 50% cheaper than imports |

Municipal repairs, mountain road construction |

4,500–6,500 hours |

|

|

Liugong |

Liugong Motor + Guangxi Weixiang Reducer |

High gear: dust-resistant; Low gear: stable lock (no shakes) |

Dust-proof; spins gracefully even in dusty gravel yards |

Gravel yard operations, roadbed construction |

4,000–5,500 hours |

IV. Maintenance Tips: 5 Steps to Keep Your Excavator Spinning Gracefully for 3 More Years

To keep the swing system in top shape and the excavator spinning gracefully, follow these 5 simple maintenance steps—even beginners can do them, saving thousands in repairs:

1. "Gentle" Operation: No Sudden Brakes or Jerky Spins

• Push/pull the swing joystick slowly to accelerate/decelerate smoothly—avoid sudden stops.

• Use low gear for heavy loads and high gear for empty spins. Never "use high gear for heavy loads"—this keeps spins stable.

2. "Clean" Oil Changes: Feed the Swing System Clean Oil

• Hydraulic Oil: Change every 2,000 hours for heavy-duty work (e.g., mining) or 3,000 hours for light work (e.g., municipal projects). Keep the oil level between "MIN" and "MAX"—never run low.

• Filters: Replace the "swing system-specific filter" (some share the main hydraulic filter) every time you change the oil. Check it every 500 hours—replace if dirty to keep contaminants out.

3. Weekly "Checks": Catch Spin Issues Early

• Leak Checks: Inspect the swing system’s seals and oil pipe joints for leaks (leaked oil leaves stains on the chassis). Replace seals immediately if leaks are found.

• Noise Checks: Listen to the swing system while spinning—normal operation makes a "steady hum". A "clunking or squealing sound" means parts are faulty—don’t keep using it.

• Lock Checks: After parking on flat ground, try moving the swing joystick. The upper structure should stay fixed (if the lock works). If it moves, repair the lock immediately.

4. Avoid "Collisions": Check Surroundings Before Spinning

Always look around for utility poles, trucks, or workers before spinning—especially in tight sites. Spin slowly to avoid hitting obstacles and damaging the swing system.

5. "Spin" During Long Downtime: Don’t Let the System Rust

If the excavator is unused for over a month, start it every 10 days. Spin it 3–5 times in low gear, then 3–5 times in high gear. This circulates hydraulic oil, preventing rust and seal aging.

V. Conclusion

To make a tens-of-tons excavator spin as gracefully as a ballerina, the core lies in its swing system (swing reducer + swing motor). Beginners should remember 3 key points:

1. Use the Right Gear: High gear for empty spins (saves time); low gear for heavy loads (stays steady)—this ensures elegant spins.

2. Choose the Right Brand: International brands (Caterpillar, Volvo) for heavy work; domestic brands (Sany, XCMG) for light work—this ensures durability.

3. Maintain Properly: Operate gently, use clean oil, and check weekly. These steps keep the swing system working well for 3 more years, saving repair costs.

A well-maintained swing system lets your excavator spin smoothly and steadily—boosting work efficiency and saving money. That’s what "elegant and practical" really means!

About SPARKLING MACHINERY:

- Founded in 2013, SPARKLING focuses on high-quality excavator parts across hydraulics, undercarriage, engines and electrical systems. We prioritize stability, precision and continuous service, offering worldwide distribution, tailored solutions and strict QC to help customers reduce cost and increase uptime.

Get In Touch:

- Replace your failing ECU confidently. Contact SPARKLING for pricing, lead time, and technical support — restore optimal machine control quickly and reliably.

Hyundai & Doosan Wheel Excavator Parts Supplier | Complete Range of Replacement Components

Kubota Error Codes: A Comprehensive Diagnostic & Reset Manual

How to Resolve Error Code P0037: A Comprehensive Guide

The Definitive Guide to Excavator Diesel Engine Turbochargers: Maximizing Power with High-Performance Forced-Induction Core Components

The Ultimate Guide to Excavator Parts: Anatomy, Functionality & Future Trends for 2026

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

CATERPILLAR EXCAVATOR 349 541-1387 5411387 OIL COOLER ASSY CHINA MADE

CATERPILLAR EXCAVATOR 349 541-1387 5411387 OIL COOLER ASSY CHINA MADE

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Temperature sensor 14509344 16688307 For Volvo EC210B EC290C L60F L70F

Temperature sensor 14509344 16688307 For Volvo EC210B EC290C L60F L70F

KOBELCO EXCAVATOR SK115SR SK135SR YV22E00001F8 YV22E00001F5 CPU CONTROLLER UNIT ORIGINAL

KOBELCO EXCAVATOR SK115SR SK135SR YV22E00001F8 YV22E00001F5 CPU CONTROLLER UNIT ORIGINAL

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX70 ZX85US-3 ZX75US-3 4446258 CYL;BUCKET SPARKLING MACHINERY

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX70 ZX85US-3 ZX75US-3 4446258 CYL;BUCKET SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 140M 330D 336D 336D2 265-1401 PISTON SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 140M 330D 336D 336D2 265-1401 PISTON SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 551-0841+524-5566+6V-5589 PISTON KIT SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 551-0841+524-5566+6V-5589 PISTON KIT SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW C9 CX31-C9I TH31-E61 250-7701 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW C9 CX31-C9I TH31-E61 250-7701 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 350 594-7756 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 350 594-7756 TURBO SPARKLING MACHINERYGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879