Excavator Main Hydraulic Pump: Essential Knowledge You Can’t Miss

This article focuses on the main hydraulic pump, a core component of excavators. It details the main pump’s role and significance in excavators, summarizes factors that pose threats to it, compares the cost-effectiveness of main pump types across domestic and foreign excavator brands, provides practical maintenance guidelines, and concludes with key insights—helping readers fully understand and effectively manage the excavator’s main hydraulic pump.

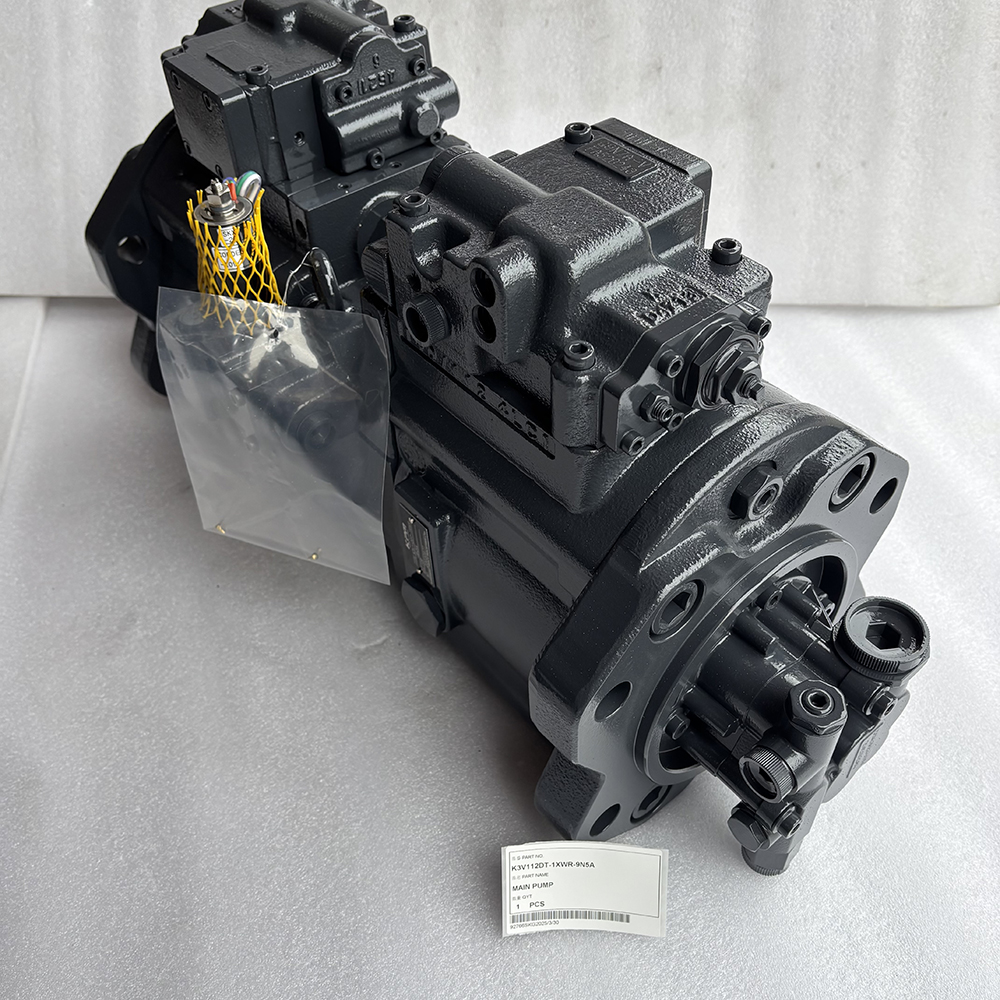

I. Introduction to the Main Hydraulic Pump

• As the "power core" of the excavator’s hydraulic system, the main hydraulic pump is responsible for converting the mechanical energy from the excavator’s engine into hydraulic energy. It draws hydraulic oil from the oil tank, pressurizes it, and then delivers high-pressure hydraulic oil to various actuators (such as boom cylinders, arm cylinders, and travel motors) via hydraulic pipelines—enabling the excavator to perform operations like lifting, lowering, rotating, and moving.

• Without a properly functioning main hydraulic pump, the excavator’s hydraulic system loses its power source, rendering the excavator unable to carry out any operational tasks. A high-performance main hydraulic pump directly determines the excavator’s working efficiency, response speed, and operational stability. For instance, a well-matched main hydraulic pump can reduce energy loss, allowing the excavator to achieve faster digging cycles and handle heavier loads.

• It acts as a key link in coordinating the excavator’s overall performance. By adjusting the main hydraulic pump’s output flow and pressure based on the excavator’s working conditions (e.g., light load, heavy load, or idling), it ensures the excavator adapts to different construction scenarios (such as earth excavation, rock breaking, or precision hoisting) while avoiding unnecessary energy waste and component wear.

II. What the Main Hydraulic Pump Fears Most

• Contaminated hydraulic oil: Impurities (such as metal shavings, dust, and sludge) in hydraulic oil can scratch the inner cavity of the main hydraulic pump, damage precision mating parts (e.g., plungers and cylinder blocks), and block oil passages. This leads to increased internal leakage of the pump, reduced output pressure, and even severe failures like pump seizure.

• Oil shortage or insufficient oil level: If the hydraulic oil level is too low, the main hydraulic pump cannot draw in enough oil, resulting in cavitation (air bubble formation in the oil). These air bubbles burst under high pressure, generating shock waves that erode the pump’s internal components—causing abnormal noise, reduced pump efficiency, and accelerated wear.

• Hydraulic system overheating: Prolonged high-temperature operation (typically when hydraulic oil temperature exceeds 65°C) degrades the performance of hydraulic oil—its viscosity decreases, lubricating ability declines, and the seal rings in the main hydraulic pump age and lose their sealing effect. This not only increases internal leakage of the pump but also shortens the service life of the pump’s core components.

• Improper operation: Frequent rapid switching of the excavator’s control lever (causing sudden changes in hydraulic pressure and flow), long-term overload operation (forcing the main hydraulic pump to work under excessive pressure for extended periods), or starting the pump at full load—all these actions exert excessive stress on the main hydraulic pump, leading to premature fatigue damage of parts and reduced pump reliability.

III. Cost-Effectiveness of Main Hydraulic Pump Types by Excavator Brand

|

Brand Category |

Brand Name |

Main Hydraulic Pump Type |

Cost-Effectiveness Highlights |

|

Domestic Brands |

Sany Heavy Industry |

"A8V Variable Displacement Axial Piston Pump" (co-developed with Bosch Rexroth) |

Applied in medium and large excavators (e.g., SY215C, SY365H). High volumetric efficiency (up to 95%), stable pressure output, low energy consumption. Reduces fuel consumption by 8-12% vs. ordinary pumps; service life: 8,000-10,000 working hours. Ideal for large-scale earthwork and mining projects. |

|

|

XCMG |

Independently developed "PVG Series Proportional Variable Piston Pump" |

Equipped in excavators (e.g., XE200DA, XE490DK). Strong anti-pollution capability, easy maintenance (local availability of common spare parts). Failure rate 15-20% lower than imported pumps; maintenance cost ~30% lower than imports. Suitable for users prioritizing low long-term maintenance costs. |

|

|

Liugong |

"K3V Series Axial Piston Pump" (authorized production by Kawasaki) |

Used in mainstream excavators (e.g., CLG920E, CLG950E). Good adaptability to harsh conditions (high dust, high temperature), stable performance. Proven service life over 9,000 working hours; price ~20% cheaper than original imported Kawasaki pumps. Cost-effective for municipal engineering and road construction. |

|

Foreign Brands |

Caterpillar |

Independently developed "Variable Displacement Piston Pump Matched with CAT C7.1 Engine" |

Used in large excavators (e.g., CAT 349 GC, CAT 395). Optimal integration with engine power output—strong power under heavy loads (e.g., rock excavation) and low fuel consumption. Initial cost 25-30% higher than domestic pumps, but service life (12,000-15,000 working hours) and low failure rate (<5% within 8,000 hours) make it cost-effective for long-term, high-intensity projects. |

|

|

Komatsu |

"HPV Series Axial Piston Pump" |

Equipped in excavators (e.g., PC200-11, PC360LC-11). Precise flow control, smooth operation (reduces hydraulic shock impact on excavator structure), low noise. Ideal for precision construction (e.g., building foundation excavation, pipeline laying). Excellent overall cost-effectiveness with balanced initial investment and long-term usage costs. |

|

|

Volvo Construction Equipment |

"Linde B Series Variable Piston Pump" (customized cooperation) |

Used in excavators (e.g., EC220EL, EC380EL). High energy efficiency—automatically adjusts output flow and pressure based on load to reduce unnecessary energy waste. Performs well in low-temperature environments (works normally at -30°C); service life: 10,000-12,000 working hours. Cost-effective for users in cold regions or those focusing on energy conservation. |

IV. How to Maintain the Main Hydraulic Pump

• Regularly check and replace hydraulic oil and oil filters: Replace hydraulic oil strictly in accordance with the excavator’s maintenance manual (usually every 2,000-2,500 working hours) and use the oil grade specified by the manufacturer (e.g., ISO VG 46 hydraulic oil). Replace the suction filter, return oil filter, and pressure filter simultaneously to ensure effective filtration of impurities and prevent oil contamination from damaging the main hydraulic pump.

• Keep hydraulic oil level and temperature within normal ranges: Check the hydraulic oil level before starting the excavator daily—ensure the oil level is between the "MIN" and "MAX" marks on the oil level gauge. During operation, monitor the hydraulic oil temperature via the excavator’s instrument panel; if the temperature exceeds 65°C, stop the machine immediately to cool down and identify the cause (e.g., blocked radiator, insufficient oil) to avoid pump damage from overheating.

• Conduct daily inspections and troubleshooting: Before each shift, inspect the main hydraulic pump’s oil pipes, joints, and seal rings for oil leakage. If leakage is found, tighten the joints or replace the seals promptly to prevent oil shortage and air intake. Listen to the main hydraulic pump’s operating sound during operation—if abnormal noise (e.g., sharp squealing, dull knocking) occurs, stop the machine to check for issues (e.g., cavitation, component wear, oil contamination) and resolve them immediately.

• Standardize operation and avoid overload: Train operators to operate the excavator in a standardized manner—avoid rapid lever switching, long-term overload operation, or full-load pump startup. For example, when the excavator encounters hard materials (e.g., rocks), do not force excavation; instead, use a breaker to crush the materials first to reduce the load on the main hydraulic pump.

• Arrange regular professional maintenance and inspection: Every 5,000-6,000 working hours, invite professional technicians to disassemble and inspect the main hydraulic pump—check the wear of core components (e.g., plungers, cylinder blocks, valve plates), measure the pump’s internal clearance, and replace severely worn parts. Meanwhile, perform precision debugging of the pump’s pressure and flow to ensure it operates within the optimal performance range.

V. Conclusion

The main hydraulic pump is the core power component of an excavator, and its performance and service life directly affect the excavator’s operational efficiency, construction costs, and reliability. By understanding the main pump’s importance, avoiding harmful factors (e.g., oil contamination, oil shortage, overheating), selecting excavator brands with cost-effective main pumps based on project needs, and implementing standardized maintenance measures, users can maximize the main hydraulic pump’s service life, reduce failure rates and maintenance costs, and ensure the excavator maintains stable and efficient operation in various construction scenarios. For excavator operators, maintenance personnel, and procurement managers, mastering this knowledge is crucial for improving equipment management capabilities and project economic benefits.

About SPARKLING MACHINERY:

- Founded in 2013, SPARKLING focuses on high-quality excavator parts across hydraulics, undercarriage, engines and electrical systems. We prioritize stability, precision and continuous service, offering worldwide distribution, tailored solutions and strict QC to help customers reduce cost and increase uptime.

Get In Touch:

- Replace your failing ECU confidently. Contact SPARKLING for pricing, lead time, and technical support — restore optimal machine control quickly and reliably.

Hyundai & Doosan Wheel Excavator Parts Supplier | Complete Range of Replacement Components

Kubota Error Codes: A Comprehensive Diagnostic & Reset Manual

How to Resolve Error Code P0037: A Comprehensive Guide

The Definitive Guide to Excavator Diesel Engine Turbochargers: Maximizing Power with High-Performance Forced-Induction Core Components

The Ultimate Guide to Excavator Parts: Anatomy, Functionality & Future Trends for 2026

faq

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

CATERPILLAR EXCAVATOR 349 541-1387 5411387 OIL COOLER ASSY CHINA MADE

CATERPILLAR EXCAVATOR 349 541-1387 5411387 OIL COOLER ASSY CHINA MADE

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Hyundai Made In China Sparkling Machinery New r200w-7 r200w-7a Zgaq-02342 Fork-Joint 8.8kg

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

Temperature sensor 14509344 16688307 For Volvo EC210B EC290C L60F L70F

Temperature sensor 14509344 16688307 For Volvo EC210B EC290C L60F L70F

KOBELCO EXCAVATOR SK115SR SK135SR YV22E00001F8 YV22E00001F5 CPU CONTROLLER UNIT ORIGINAL

KOBELCO EXCAVATOR SK115SR SK135SR YV22E00001F8 YV22E00001F5 CPU CONTROLLER UNIT ORIGINAL

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX70 ZX85US-3 ZX75US-3 4446258 CYL;BUCKET SPARKLING MACHINERY

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX70 ZX85US-3 ZX75US-3 4446258 CYL;BUCKET SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 140M 330D 336D 336D2 265-1401 PISTON SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 140M 330D 336D 336D2 265-1401 PISTON SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 551-0841+524-5566+6V-5589 PISTON KIT SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 551-0841+524-5566+6V-5589 PISTON KIT SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW C9 CX31-C9I TH31-E61 250-7701 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW C9 CX31-C9I TH31-E61 250-7701 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 350 594-7756 TURBO SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 350 594-7756 TURBO SPARKLING MACHINERYGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879