Tracked vs. Wheeled Excavators: Which Is the "Workhorse" for Your Construction Site?

Did your excavator get stuck on the construction site during the rainy season in southern China, costing you $700 in towing fees and delaying the project by 3 days? When doing municipal repairs in the city, did your tracked excavator damage the road surface (leading to compensation) and force you to wait for a flatbed truck to move it between sites? Stop losing money due to poor excavator selection!

Now, we’ll help you solve this problem once and for all: from complex mountainous terrain to narrow urban alleys, from heavy-duty mining operations to scattered tasks across multiple sites, we’ll teach you how to match tracked and wheeled excavators to the right scenarios. We’ll also break down the "core advantages" of four popular models: Caterpillar 349 GC, Komatsu PC360LC, Hitachi ZX170W, and Volvo EWR170E. In just 3 minutes, you’ll not only avoid pitfalls like getting stuck, rework, and high maintenance costs but also directly identify the "cost-effective and efficient option" that best fits your construction site!

- I. Tracked vs. Wheeled Excavators: Which Is Better Suited for Your Construction Site?

- 1. Tracked Excavators: Reliable for Complex Terrain and Heavy-Duty Work

- Advantages:

- Disadvantages:

- Representative Brand Models:

- 2. Wheeled Excavators: Cost-Effective and Flexible for Urban Operations

- Advantages:

- Disadvantages:

- Representative Brand Models:

- One-Sentence Summary:

- II. Why Don’t Tracked Excavators Sink in Soft Ground, But Wheeled Ones Do? The Key Is "Ground Pressure"!

- Representative Brand Models:

- III. Summary

I. Tracked vs. Wheeled Excavators: Which Is Better Suited for Your Construction Site?

1. Tracked Excavators: Reliable for Complex Terrain and Heavy-Duty Work

Advantages:

• No Sinking in Soft Ground, No Fear of Steep Slopes: The ground contact area of tracks is 3-5 times larger than that of wheeled excavators of the same tonnage, with a ground pressure of ≤0.15MPa. They can move steadily in marshes, farmland, and on slopes steeper than 25°, making them ideal for construction during the rainy season in southern China and mountain road construction.

• Ultra-Stable for Heavy-Duty Operations: Track pads feature anti-slip grooves and independent left/right track drives, minimizing rework when digging deep foundations or loading heavy aggregates. They are indispensable for large-scale mining and infrastructure projects.

• Durable and Rugged: Failure rates are 30% lower than wheeled excavators in harsh working conditions, ensuring peace of mind during long-term high-intensity operations.

Disadvantages:

• Slow and Costly Transportation Between Sites: Maximum speed is only 3-5 km/h, requiring flatbed trucks for inter-site transport. A one-way trip for a 20-ton model costs 210-420.

• Damages Hard Surfaces and High Maintenance Costs: Prolonged travel on concrete or asphalt roads easily damages the pavement. Replacing a full set of tracks costs 2,800-7,000.

• Difficult to Operate in Tight Spaces: Large turning radius often leads to bottlenecks when digging trenches in residential areas or working in underground garages.

Representative Brand Models:

• Caterpillar 349 GC: Equipped with reinforced track pads and deep anti-slip grooves, it has a ground pressure as low as 0.14MPa, preventing sinking in marshes in southern China. Its built-in "Slope Assist" function enables precise angle control on slopes steeper than 25°, making it the top choice for mining crushing and deep foundation excavation.

• Komatsu PC360LC: Features an exclusive "Terrain Adaptive System" that automatically adjusts track tension, keeping the machine stable on soft farmland or hillsides. It also includes anti-roll sensors, maximizing safety during roadbed construction and mountain excavation—reliable for rainy-season operations.

2. Wheeled Excavators: Cost-Effective and Flexible for Urban Operations

Advantages:

• Fast and Cost-Free Inter-Site Movement: With a speed of 25-40 km/h, it can travel independently to sites within 5 km without waiting for a flatbed truck, saving 210-420 in transport fees and 1-2 hours of travel time.

• No Damage to Hard Surfaces: Wear-resistant industrial tires avoid scratching concrete or asphalt roads, eliminating compensation risks during municipal repairs or residential construction. Replacing a full set of tires costs only 700-1,680.

• Ultra-Flexible in Tight Spaces: Turning radius is half that of tracked excavators, enabling easy U-turns in underground garages or narrow alley pipeline construction—20% more efficient than tracked models.

Disadvantages:

• Prone to Sinking in Soft Ground: High ground pressure (0.3-0.5MPa) often leads to sinking in rain-soaked farmland or sandy soil, requiring towing services that cost over $280 and delaying the project.

• Incapable of Heavy-Duty Work or Steep Slope Operations: Wobbles when digging trenches deeper than 3 meters and slips on slopes steeper than 15°, making it unsuitable for mining or mountainous projects.

• Lower Durability: Tires have poor impact resistance, easily puncturing in gravel-rich sites—frequent repairs and replacements increase costs.

Representative Brand Models:

• Hitachi ZX170W: Fuel-efficient engine reduces inter-site travel costs by 15% compared to similar models. Its compact design allows flexible movement during residential trench digging or municipal repairs, making it the first choice for scattered tasks across multiple sites.

• Volvo EWR170E: Equipped with a "Quick Shift" system, it reaches speeds of 40 km/h for smooth acceleration during transport. With a turning radius of only 4.2 meters, it easily maneuvers in underground garages—perfect for urban renewal projects.

One-Sentence Summary:

Tracked excavators (Caterpillar 349 GC, Komatsu PC360LC) are suitable for heavy-duty work on complex terrain; wheeled excavators (Hitachi ZX170W, Volvo EWR170E) are ideal for flexible operation scenarios.

II. Why Don’t Tracked Excavators Sink in Soft Ground, But Wheeled Ones Do? The Key Is "Ground Pressure"!

Many people wonder: Why can a 20-ton tracked excavator move on soft ground without sinking, while a wheeled one of the same tonnage cannot? The core reason is ground pressure—the pressure exerted by the machine’s weight on the ground. Lower pressure means less likelihood of sinking!

• Tracked Excavators: Distribute Weight Evenly: For example, a 20-ton tracked excavator has a total ground contact area of approximately 1.3㎡, resulting in a pressure of only 1.5 kg per square centimeter (equivalent to an apple resting on a table). Soft ground can easily withstand this pressure. Additionally, track pads make continuous contact with the ground, ensuring uniform weight distribution and further reducing the risk of sinking.

• Wheeled Excavators: Concentrate Weight: A 20-ton wheeled excavator has a total ground contact area of only 0.2㎡ via its four tires, creating a pressure of 10 kg per square centimeter (equivalent to 10 apples stacked on a table). Soft ground is instantly compressed into pits, and spinning tires only deepen the sinkage—eventually requiring rescue.

Representative Brand Models:

• Tracked Excavators (Caterpillar, Komatsu): The Caterpillar 349 GC has a ground contact area of 1.3㎡ and a pressure of only 1.5 kg/cm² (like an apple on a table), easily handling soft ground. The Komatsu PC360LC further reduces pressure with widened tracks, ensuring stability even in marshes.

• Wheeled Excavators (Hitachi, Volvo): The Hitachi ZX170W has a ground contact area of only 0.2㎡ and a pressure of up to 10 kg/cm² (like 10 stacked apples), instantly sinking in soft ground. Although the Volvo EWR170E uses lightweight materials to reduce weight, it still cannot match the low-pressure advantage of tracked excavators.

III. Summary

When choosing an excavator, avoid following trends blindly. Focus on two core factors: construction site terrain and type of work:

• If your site is in a mine, mountain, or marsh, and requires deep foundation digging or heavy material loading—choose a tracked excavator! Prioritize the Caterpillar 349 GC (excellent for mining) or Komatsu PC360LC (stable for mountainous areas). Although transport and maintenance costs are higher, they prevent sinking and rework, ultimately saving money.

• If your site is in an urban area, and involves municipal repairs, residential renovations, or scattered tasks across multiple sites—choose a wheeled excavator! Opt for the Hitachi ZX170W (fuel-efficient) or Volvo EWR170E (fast transport). Their flexibility and non-damaging nature to roads will save you the price difference in the short term.

Remember: There is no "best" excavator—only the one that best fits your construction site as a "workhorse"! Next time you select equipment, match brand models to your site’s needs, and you’ll avoid costly mistakes!

About SPARKLING MACHINERY:

- Founded in 2013, SPARKLING focuses on high-quality excavator parts across hydraulics, undercarriage, engines and electrical systems. We prioritize stability, precision and continuous service, offering worldwide distribution, tailored solutions and strict QC to help customers reduce cost and increase uptime.

Get In Touch:

- Replace your failing ECU confidently. Contact SPARKLING for pricing, lead time, and technical support — restore optimal machine control quickly and reliably.

Top 15 Excavator Parts Manufacturers for 2026

Understanding the Key Parts of an Excavator and Their Functions 2026

Ultimate Guide to Hydraulic Cylinder Components: Anatomy, Function, & Selection for 2025 and Beyond

Christmas Excavators: From Construction Sites to Holiday Heroes!

Volvo Excavator Hydraulic Pump Selection Guide: Original vs. China-Made – How to Choose Without Pitfalls?

faq

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW PC220 PC240 PC290 PC300 PC350 20Y-54-52860 LOCK ASS'Y SPARKLING MACHINERY

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW PC220 PC240 PC290 PC300 PC350 20Y-54-52860 LOCK ASS'Y SPARKLING MACHINERY

Kobelco HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW SK200LC-6ES SK235SRLC-1ES SK235SR-1ES ME077148 RELAY,ALTNT SPARKLING MACHINERY

Kobelco HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW SK200LC-6ES SK235SRLC-1ES SK235SR-1ES ME077148 RELAY,ALTNT SPARKLING MACHINERY

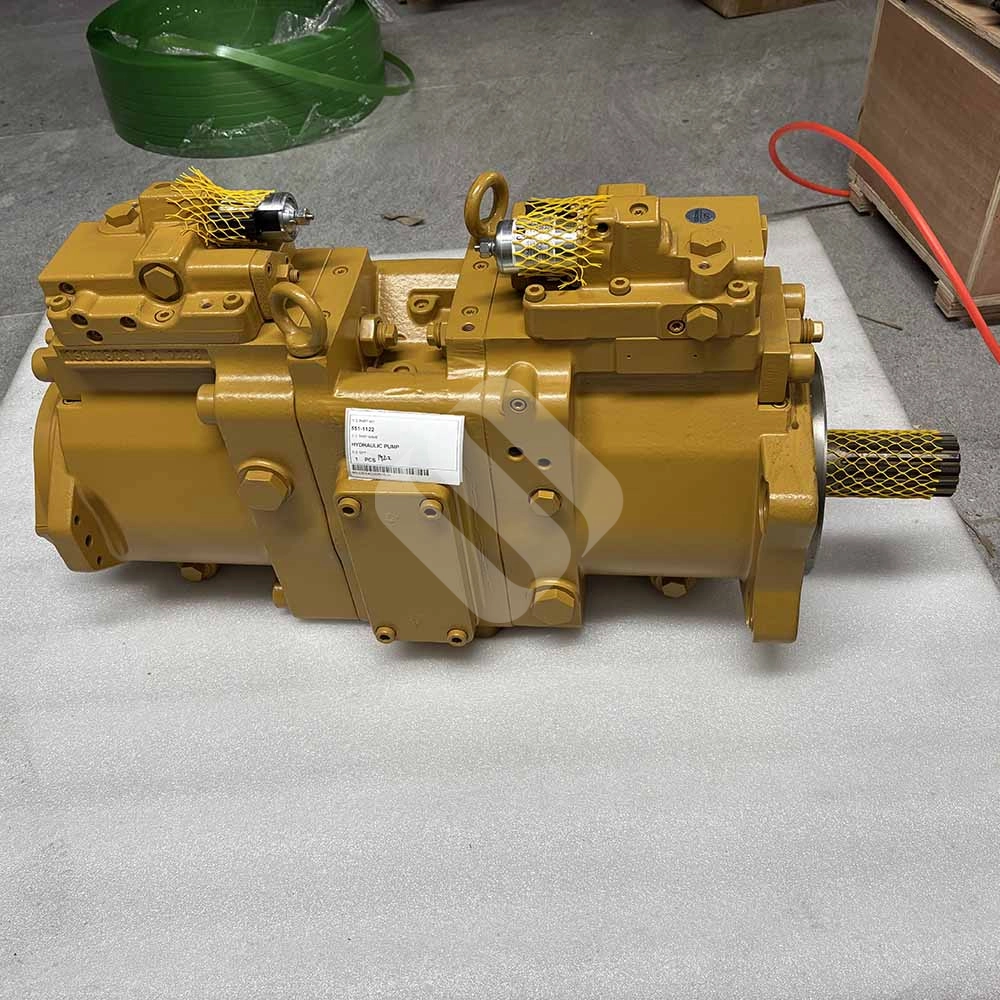

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 330 330GC 551-1122 HYDRAULIC PUMP SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 330 330GC 551-1122 HYDRAULIC PUMP SPARKLING MACHINERY

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW DX180 K9004306 GEAR DRIVE SPARKLING MACHINERY

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW DX180 K9004306 GEAR DRIVE SPARKLING MACHINERY

Atlas Copco HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 1089037601 TEMPERATURE SWITCH SPARKLING MACHINERY

Atlas Copco HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 1089037601 TEMPERATURE SWITCH SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 302.7D 386-0875 3860875 RELIEF VALVE SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 302.7D 386-0875 3860875 RELIEF VALVE SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 120G 120H 130G 140G 140H 135H 6L-8617 RADIATOR CAP SPARKLING MACHINERY

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 120G 120H 130G 140G 140H 135H 6L-8617 RADIATOR CAP SPARKLING MACHINERY

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW FV30 ZX450 ZX450H ZX450H-HHE ZX460LCH-AMS 4435106 CUSHION SPARKLING MACHINERY

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW FV30 ZX450 ZX450H ZX450H-HHE ZX460LCH-AMS 4435106 CUSHION SPARKLING MACHINERY

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 100D-7 50DE 50DEACE 50DF 50DS-7E 80D-7 11LD-20240 HEAD FILTER SPARKLING MACHINERY

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 100D-7 50DE 50DEACE 50DF 50DS-7E 80D-7 11LD-20240 HEAD FILTER SPARKLING MACHINERY

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 301.4C 3792809 TURBOCHARGER SPARKLING MACHINERY

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 301.4C 3792809 TURBOCHARGER SPARKLING MACHINERYGet in touch

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1